Method for slowing dissolving speed of non-crosslinked gel in blockage-adjusting agent for oil field

A dissolution rate, non-crosslinking technology, applied in the field of oil and gas field chemistry, can solve problems affecting pump injection construction, pump blockage, etc., and achieve the effect of improving swelling and sticking time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

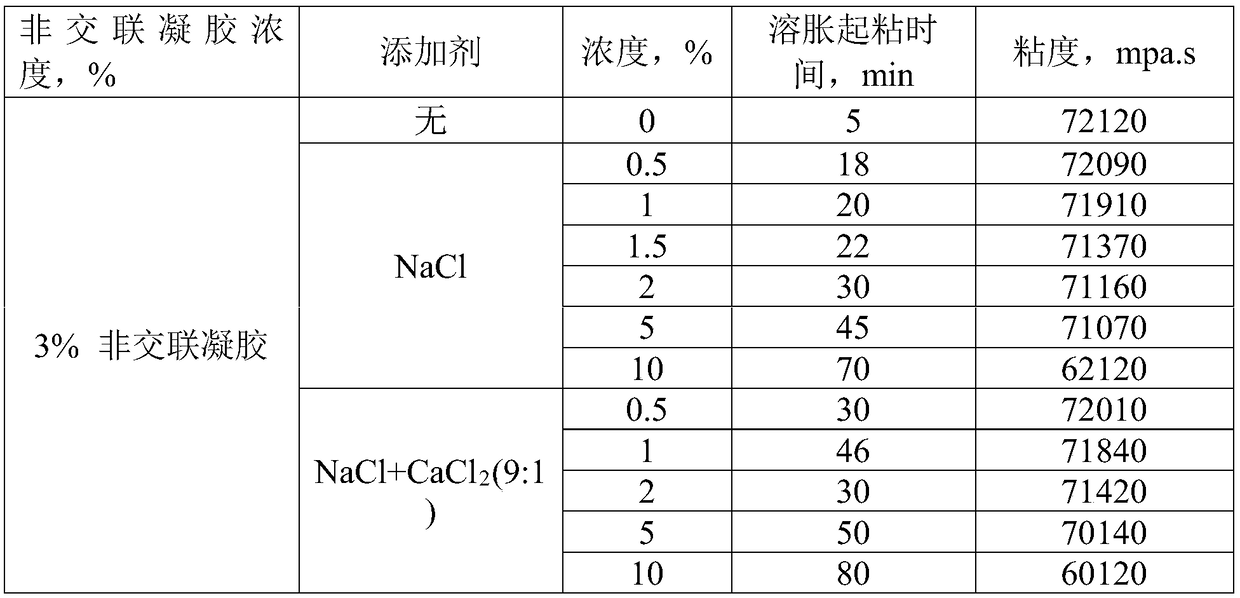

[0030] (1) The non-cross-linked gel was added into clear water to prepare a non-cross-linked gel solution with a concentration of 3% by mass, and the swelling and viscous time and viscosity of the solution were measured.

[0031] (2) Sodium chloride is dissolved in clear water to prepare saline solutions with mass percent concentrations of 0.5%, 1%, 1.5%, 2%, 5%, and 10%, respectively, and then add non- The cross-linked gel was prepared into a non-cross-linked gel solution with a concentration of 3% by mass, and the swelling and viscous time and viscosity value of the solution were measured.

[0032] (3) Sodium chloride and calcium chloride are dissolved in clear water at a mass ratio of 9:1, and the total mass percentage concentrations of sodium chloride and calcium chloride are respectively made into 0.5%, 1%, 2%, 5%, 10% salt solution, and then add non-crosslinked gel to each concentration of salt solution to prepare a non-crosslinked gel solution with a mass percent concen...

Embodiment 2

[0040] Wells 40-6-3 and 38-9 in an oilfield belong to typical complex fault-block reservoirs, with many faults, casing leakage, casing damage, casing deformation, and casing damage. Water accidents cause pollution of wetlands, farmland, villages and farms. High formation pressure caused by high injection-production ratio, coupled with the fact that old wells have been abandoned for a long time, the original wellhead cannot be found after the surface is restored, casing damage and leakage, pipe leakage, fault blocks and many other factors are potential factors, making this type of accident There are many difficulties in the processing measures. The use of various plugging agents to control the problem of ground water channeling has ended in failure, such as: cement plugging (near wellbore plugging), chemical cross-linked gel plugging (formation gelation performance and uncontrollable plugging position), Walnut shell rubber powder inorganic material plugging (plugging near the ...

Embodiment 3

[0044] Environmental protection treatment of a certain oilfield: due to poor early cementing quality, insufficient cement return height, poor casing material, and development time of more than 40 years in a certain oilfield, there are many casing corrosion, perforation and fractures, and the formation crude oil has a high gas content pressure coefficient High and high pressure fluids enter the leakage point through the cement annulus, and then enter the under-compacted formation on the surface, causing ground leakage and affecting environmental protection. It is recommended to seal the underground leakage point in the well area to ensure the normal opening of the oil field and environmental protection .

[0045] The construction process is as follows: starting the production string, drilling the well, washing the well, lowering the construction string, pressure testing, construction equipment entering the site, construction materials entering the site, and construction starting...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com