Hot metal based hydraulic clay gun and use method

A liquid metal and hydraulic technology, applied to blast furnace parts, furnaces, blast furnace details, etc., can solve the problems of reducing lubrication performance, increasing system pressure loss, and reducing efficiency, so as to reduce the number of replacements, improve safety, and facilitate installation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

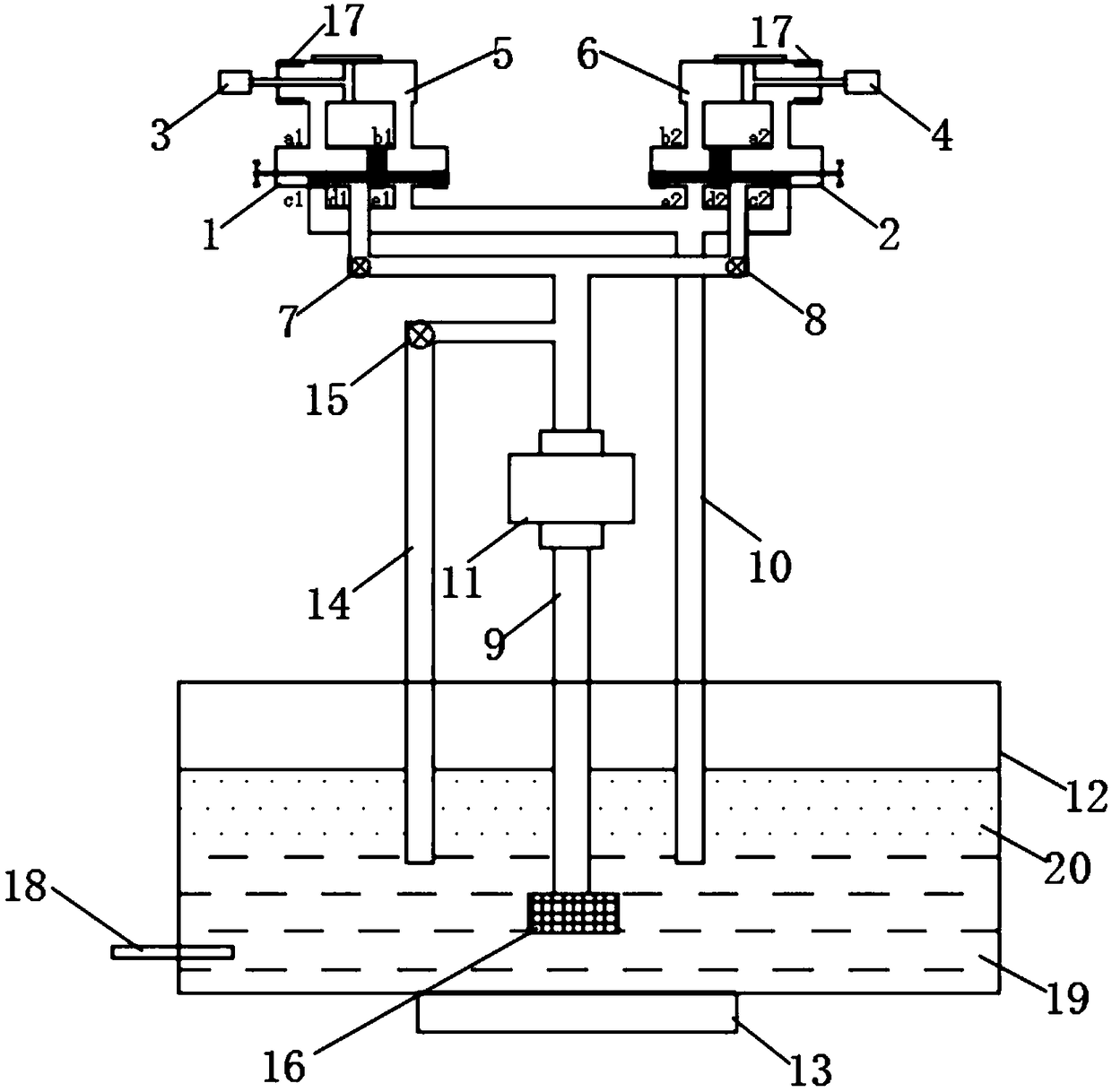

[0039] Such as figure 1As shown, the present invention provides a hydraulic mud gun based on liquid metal, the hydraulic mud gun includes a controller, a first hydraulic cylinder 5, a second hydraulic cylinder 6, a first steering valve 1, a second steering valve 2, a A flow sensor, a second flow sensor, a first valve 7, a second valve 8, an inflow pipe 9, a return pipe 10, a liquid storage tank 12 filled with liquid metal 19, a heater 13 arranged on the liquid storage tank 12, The drive pump 11 that is arranged on the inflow pipe 9, the gun mechanism 3 that is connected with the piston rod of the first hydraulic cylinder 5, and the mud-beating mechanism 4 that is connected with the piston rod of the second hydraulic cylinder 6; One port a1, the second port b1, the third port c1, the fourth port d1 and the fifth port e1, the end of the first hydraulic cylinder 5 adjacent to the gun mechanism 3 communicates with the first port a1 of the first steering valve 1, the first port On...

Embodiment 2

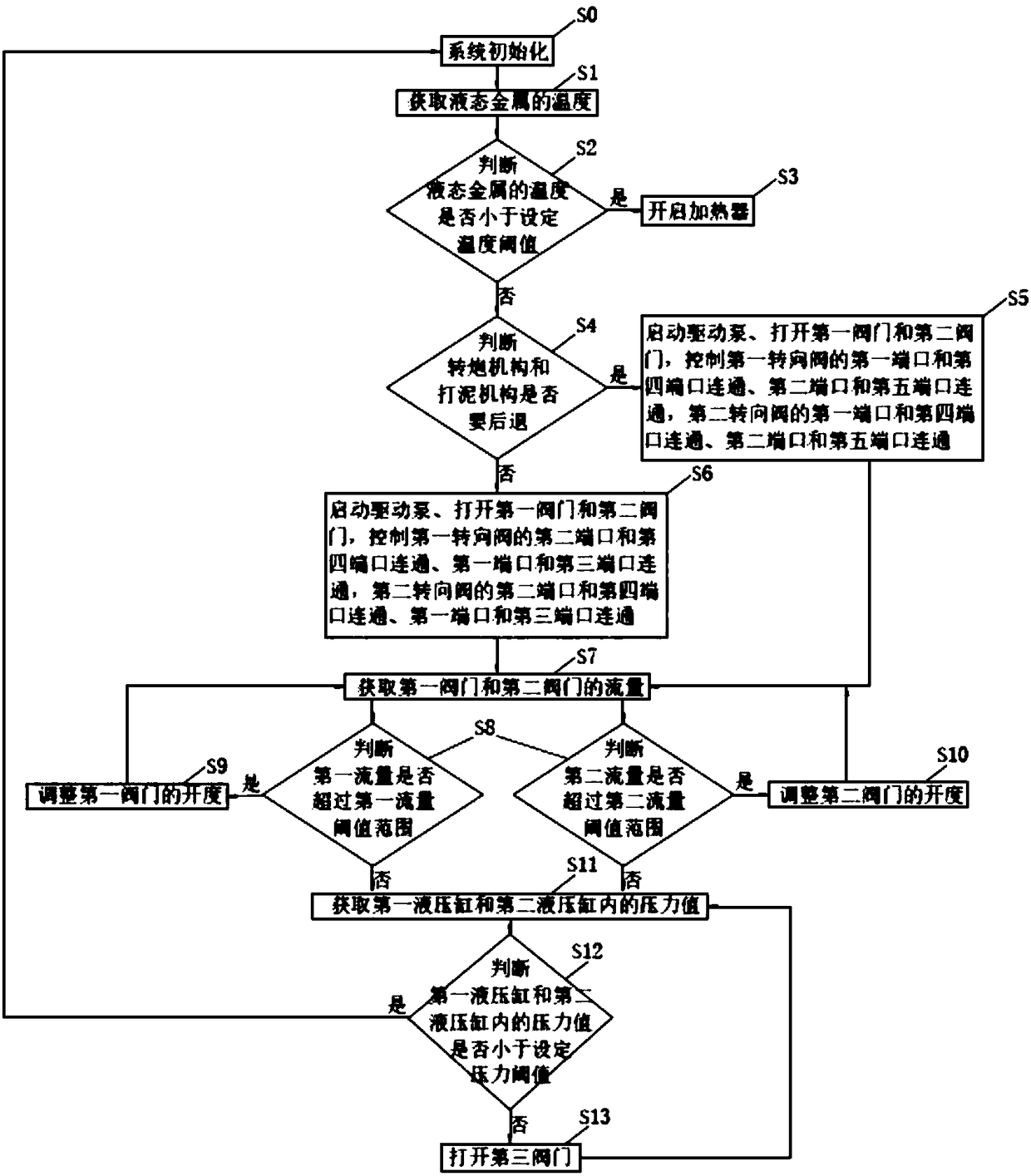

[0055] Such as figure 2 Shown, the present invention also provides a kind of using method based on liquid metal hydraulic mud cannon, and this using method comprises the following steps:

[0056] S0, system initialization, and execute step S1;

[0057] S1. Obtain the temperature of the liquid metal 19 in the liquid storage tank 12, and jump to step S2;

[0058] S2. Determine whether the temperature of the liquid metal 19 is lower than the set temperature threshold, if so, skip to step S3, and otherwise skip to step S4;

[0059] S3, turn on the heater 13, and skip to step S0;

[0060] S4. Judging whether the gun-rotating mechanism 3 and the mud-beating mechanism 4 are to retreat, if so, skip to step S5, otherwise skip to step S6;

[0061] S5. Start the driving pump 11, open the first valve 7 and the second valve 8 at the same time, and control the communication between the first port a1 of the first steering valve 1 and the fourth port d1, and the second port b1 of the firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com