A kind of phosphorus-containing polyarylether ketone and its toughened film capable of interlayer toughening dual-horse resin-based composite material

A polyaryletherketone and dual-horse resin technology, which is applied in the field of phosphorus-containing polyaryletherketone and its toughening film, can solve problems such as increasing the difficulty of resin injection, sudden increase in viscosity, composite material manufacturing process and product control impact, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

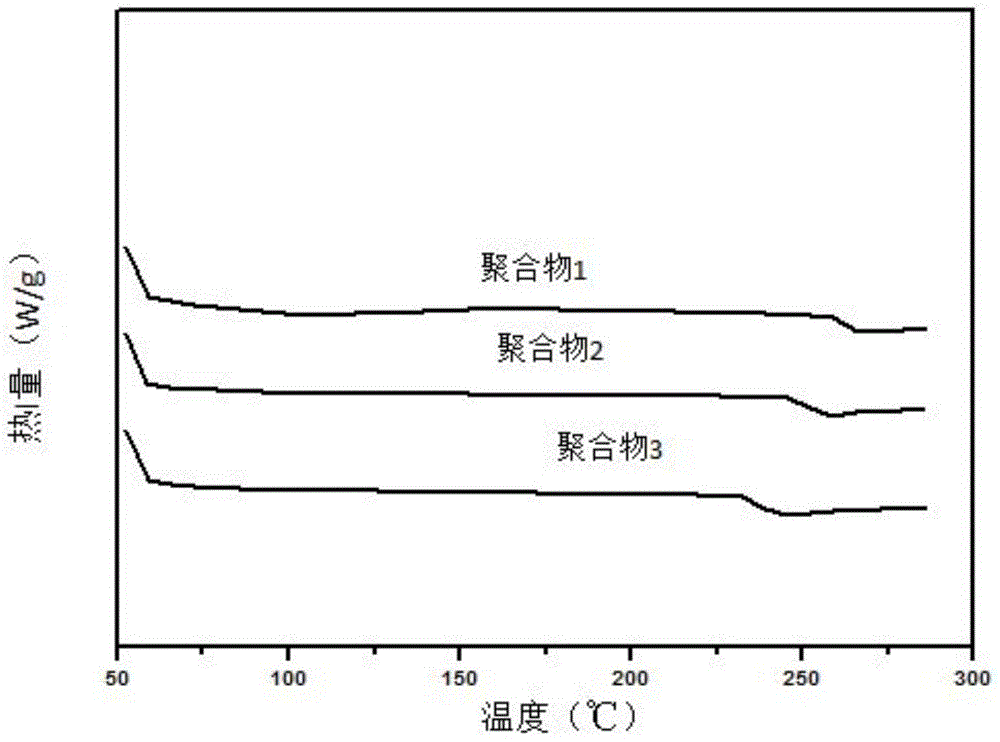

[0032] Add 31.83g (0.1mol) of phenolphthalein, 13.82g (0.1mol) of potassium carbonate, 4,4'-difluorodi Benzophenone 2.25g (0.0103mol), 4,4'-difluorodiphenylphenylphosphine 29.12g (0.0927mol), sulfolane 150ml, xylene 40ml, the solid content of the solution is about 25%.

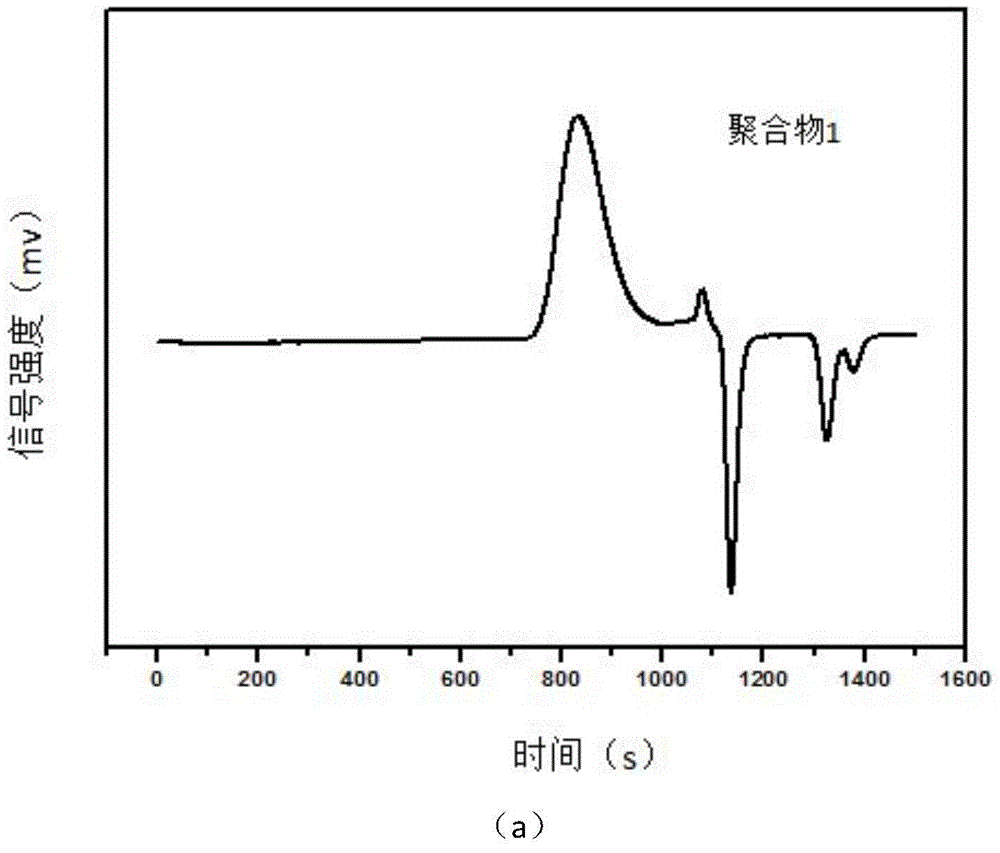

[0033] Introduce nitrogen protection, reflux reaction at 200°C for 4 hours, distill out the xylene, raise the temperature to 220°C, and react for 4 hours to obtain a viscous reaction product, which is slowly poured into distilled water in the form of white strips, and passed through a pulverizer Pulverized, then boiled with deionized water 10 times to remove solvent and inorganic salts, the final product was dried in an oven at 100°C for 24 hours to obtain polymer 1, which contained 4.79% phosphorus and had a number average molecular weight of 13W.

[0034] 1.2 g of polymer 1 was dissolved in 22.8 g of N,N’-dimethylformamide to prepare a dilute solution with a mass concentration of 5%. The solution was poured...

Embodiment 2

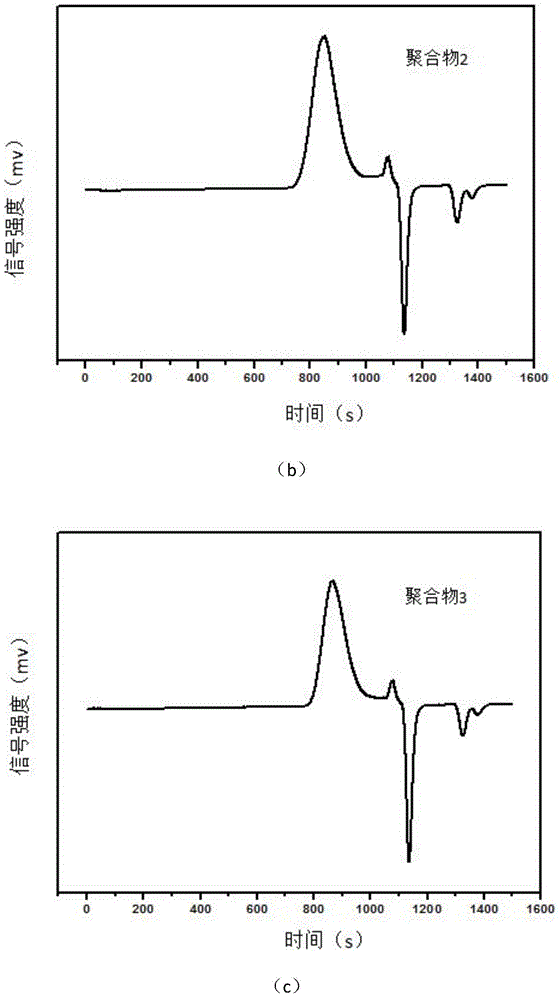

[0037]Add 31.83g (0.1mol) of phenolphthalein, 13.82g (0.1mol) of potassium carbonate, 4,4'-difluorodi Benzophenone 11.24g (0.0515mol), 4,4'-difluorodiphenylphenylphosphine 16.18g (0.0515mol), sulfolane 140ml, xylene 40ml, the solid content of the solution is about 25%. Introduce nitrogen protection, reflux reaction at 200°C for 4 hours, distill out the xylene, raise the temperature to 220°C, and react for 4 hours to obtain a viscous reaction product, which is slowly poured into distilled water in the form of white strips, and passed through a pulverizer Pulverized, then boiled with deionized water 10 times to remove solvent and inorganic salts, the final product was dried in an oven at 100°C for 24 hours to obtain polymer 2, the specific gravity of the polymer containing phosphorus was 2.85%, and the number average molecular weight was 10W.

[0038] 1.2 g of polymer 2 was dissolved in 10.8 g of N,N’-dimethylacetamide to prepare a solution with a mass concentration of 10%. Pou...

Embodiment 3

[0041] Add 31.83g (0.1mol) of phenolphthalein, 13.82g (0.1mol) of potassium carbonate, 4,4'-difluorodi Benzophenone 17.98g (0.0824mol), 4,4'-difluorodiphenylphenylphosphine 6.47g (0.0206mol), sulfolane 134ml, xylene 40ml, the solid content of the solution is about 25%. Introduce nitrogen protection, reflux reaction at 200°C for 4 hours, distill out the xylene, raise the temperature to 220°C, and react for 4 hours to obtain a viscous reaction product, which is slowly poured into distilled water in the form of white strips, and passed through a pulverizer Pulverized, then boiled 10 times with deionized water to remove solvents and inorganic salts, the final product was dried in an oven at 100°C for 24 hours to obtain polymer 3, the specific gravity of the polymer containing phosphorus was 1.20%, and the number average molecular weight was 6W.

[0042] 1.2 g of polymer 3 was dissolved in 10.8 g of chloroform to prepare a solution with a mass concentration of 10%. Pour the soluti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com