Intensifier for paper as well as preparation method and application thereof

A technology for strengthening agent and paper, applied in the direction of strengthening agent addition, etc., can solve the problems of low degree of product substitution and complex synthesis steps, and achieve the effect of expanding the scope of application, simple operation and reducing equipment investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

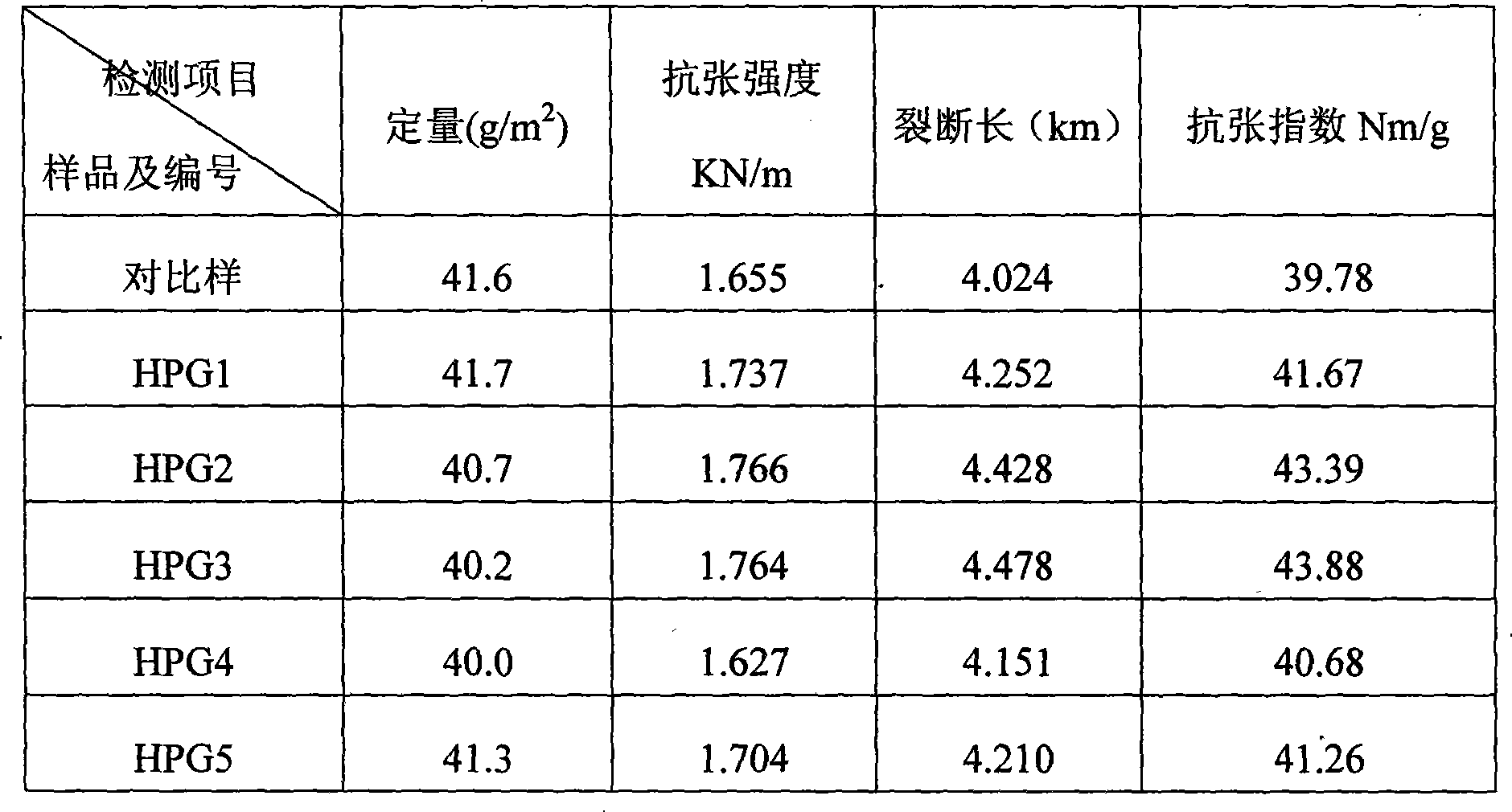

Embodiment 1

[0018] Add 32kg of ethanol and 8kg of deionized water into a 100-liter reactor, stir, add 20kg of guar collagen powder, add 0.2kg of diethanolamine while stirring, heat up to 35°C while stirring, react at this temperature for 90min, and then cool down to 25°C, replace the air with nitrogen, add 8kg of ethylene oxide in an oxygen-free atmosphere, heat up to 50°C, react at this temperature for 5 hours, then cool down to 30°C, and adjust the pH value with glacial acetic acid to Around 7.0.

[0019] The material is filtered with suction, washed once with ethanol / water mixture (ethanol: water = 9: 1), filtered with suction, washed once with 95% ethanol, washed, filtered with suction, and the filter cake is dried under vacuum at a temperature of 70°C After 2 hours, dry it, crush it, and pass through a 100-mesh sieve to get the finished product; the code is HPG1.

Embodiment 2

[0021] Add 32kg of industrial ethanol and 8kg of deionized water into a 100-liter reactor, stir, add 20kg of guar collagen powder, add 0.5kg of triethanolamine under stirring, heat up to 40°C under stirring, and react at this temperature for 75min, then Cool down to 27°C, then replace the air with nitrogen, add 10kg of ethylene oxide in an oxygen-free atmosphere, heat up to 60°C, react at this temperature for 4 hours, then cool down to 30°C, adjust the pH with glacial acetic acid value to around 7.0.

[0022] The material is filtered with suction, washed once with ethanol / water mixture (ethanol: water = 9: 1), filtered with suction, washed once with 95% ethanol, washed, filtered with suction, and the filter cake is dried under vacuum at a temperature of 70°C After 2 hours, dry and pulverize, and pass through a 100-mesh sieve to obtain a finished product, numbered HPG2.

Embodiment 3

[0024] Add 28kg of industrial ethanol and 12kg of deionized water into a 100-liter reactor, add 30kg of guar collagen powder under stirring, add 0.7kg of diethylamine under stirring, heat up to 45°C under stirring, and react at this temperature for 60min. Then cool down to 30°C, then replace the air with nitrogen, add 4.5kg of propylene oxide in an oxygen-free atmosphere, heat up to 50°C, react at this temperature for 5 hours, then cool down to 30°C, adjust with glacial acetic acid The pH value is around 7.0. The material is filtered with suction, washed once with ethanol / water mixture (ethanol: water = 9: 1), filtered with suction, washed once with 95% ethanol, washed, filtered with suction, and the filter cake is dried under vacuum at a temperature of 70°C After 2 hours, dry and pulverize, and pass through a 100-mesh sieve to obtain a finished product, numbered HPG3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com