Low emulsifier-added oil-based drilling fluid

A technology of oil-based drilling fluid and emulsifier, applied in the field of drilling fluid, can solve the problems of low demulsification voltage of drilling fluid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] In the present invention, the raw material for preparing the low-emulsifier added oil-based drilling fluid includes an emulsifier. In the present invention, the emulsifier is preferably a mixture of long-chain fatty acid amides and dimer acids. In the present invention, the mass ratio of the long-chain fatty acid amide to the dimer acid is preferably (90-100):(30-50), more preferably (92-98):(33-47), most preferably (94~96):(37~42). In the present invention, the preparation method of the long-chain fatty acid amides preferably comprises the following steps:

[0032] Under vacuum conditions, oleic acid, tall oil fatty acid, diethanolamine and triethanolamine are thermally mixed to obtain a thermal mixture;

[0033] Heat treatment of the hot mixture yields long chain fatty acid amides.

[0034] In the invention, oleic acid, tall oil fatty acid, diethanolamine and triethanolamine are thermally mixed under vacuum conditions to obtain a thermal mixture. In the present in...

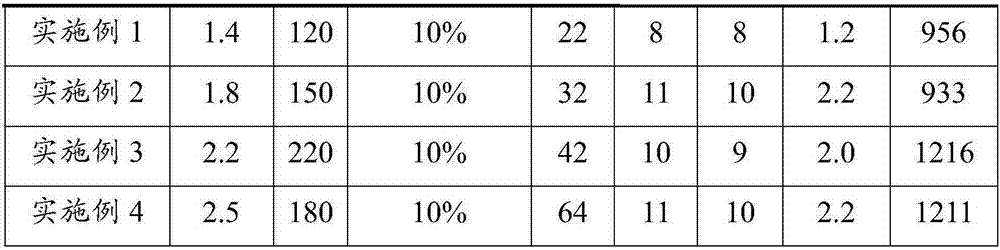

Embodiment 1

[0055] 20 parts of oleic acid and 25 parts of tall oil fatty acid are heated to 120° C., sealed and evacuated until the vacuum degree is lower than -0.1 MPa, and 30 parts of diethanolamine and 20 parts of triethanolamine are inhaled. After heat preservation reaction for 2 hours, continue to heat up to 330°C (heating time is 2h), heat preservation reaction for 2 hours, and cool to 210°C to obtain long-chain fatty acid amides. The long-chain fatty acid amide and the dimer acid are mixed according to the mass ratio of 90:40 to obtain the emulsifier.

[0056] Mix and stir 20 parts of acrylic acid and 30 parts of styrene evenly, heat to 90°C, react for 2 hours, add 20 parts of maleic anhydride, heat to 160°C, keep warm for 2 hours, and then continue to add 30 parts of tripolymer Acid, heated to 210 ° C for 2 hours to obtain modified styrene acrylic resin. The sulfonated asphalt, humic acid amide resin and modified propylene phenylacetate are mixed according to the mass ratio of 30...

Embodiment 2

[0062] 20 parts of oleic acid and 25 parts of tall oil fatty acid are heated to 120° C., sealed and evacuated until the vacuum degree is lower than -0.1 MPa, and 30 parts of diethanolamine and 20 parts of triethanolamine are inhaled. After heat preservation reaction for 2 hours, continue to heat up to 330°C (heating time is 2h), heat preservation reaction for 2 hours, and cool to 210°C to obtain long-chain fatty acid amides. The long-chain fatty acid amide and the dimer acid are mixed according to the mass ratio of 90:35 to obtain the emulsifier.

[0063] Mix and stir 20 parts of acrylic acid and 30 parts of styrene evenly, heat to 90°C, react for 2 hours, add 20 parts of maleic anhydride, heat to 160°C, keep warm for 2 hours, and then continue to add 30 parts of tripolymer Acid, heated to 210 ° C for 2 hours to obtain modified styrene acrylic resin. The sulfonated asphalt, humic acid amide resin and modified propylene phenylacetate are mixed according to the mass ratio of 30...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Plastic viscosity | aaaaa | aaaaa |

| Plastic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com