Phosphorus-containing polyaryletherketone capable of increasing interlaminar toughness of bismaleimide resin based composite material and its toughening film

A polyaryletherketone and dual-horse resin technology, which is applied in the field of phosphorus-containing polyaryletherketone and its toughening film, can solve problems such as increasing the difficulty of resin injection, sudden increase in viscosity, composite material manufacturing process and product control impact, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

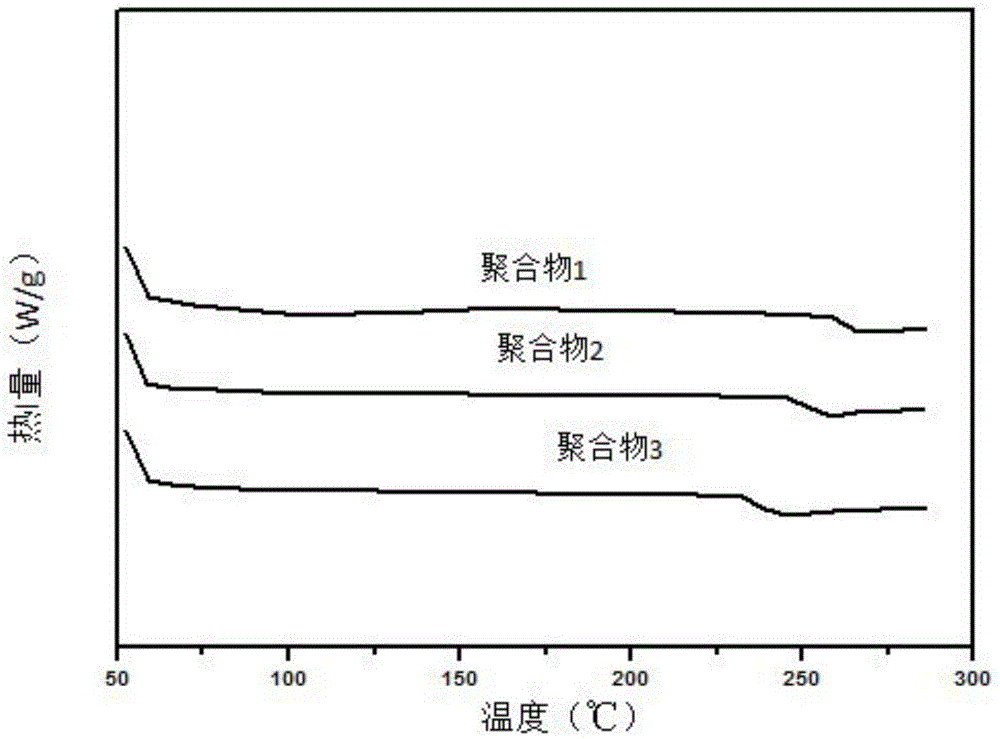

[0032] Add 31.83g (0.1mol) of phenolphthalein, 13.82g (0.1mol) of potassium carbonate, and 4,4'-difluorodifluoride into a dry three-necked flask equipped with mechanical stirring, spherical condenser, nitrogen inlet, water separator and thermometer. 2.25g (0.0103mol) of benzophenone, 29.12g (0.0927mol) of 4,4'-difluorodiphenoxy, 150ml of sulfolane, 40ml of xylene, the solid content of the solution is about 25%.

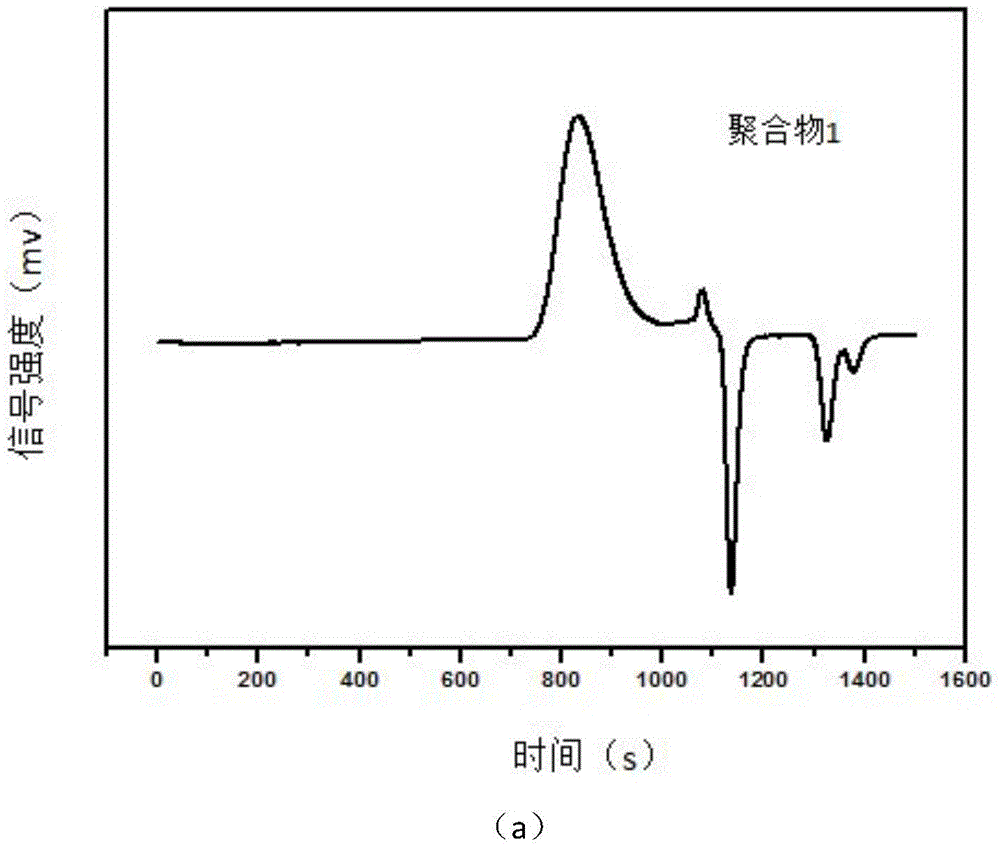

[0033] Pour in nitrogen protection, reflux at 200°C for 4 hours, then distill the xylene out, heat up to 220°C, react for 4 hours to obtain a viscous reaction product, slowly pour it into distilled water, in a white strip shape, pass through a crusher After pulverization, it was boiled with deionized water 10 times to remove the solvent and inorganic salt. The final product was dried in an oven at 100°C for 24 hours to obtain polymer 1. The polymer had a phosphorus specific gravity of 4.79% and a number average molecular weight of 13W.

[0034] Dissolve 1.2 g of polymer 1 ...

Embodiment 2

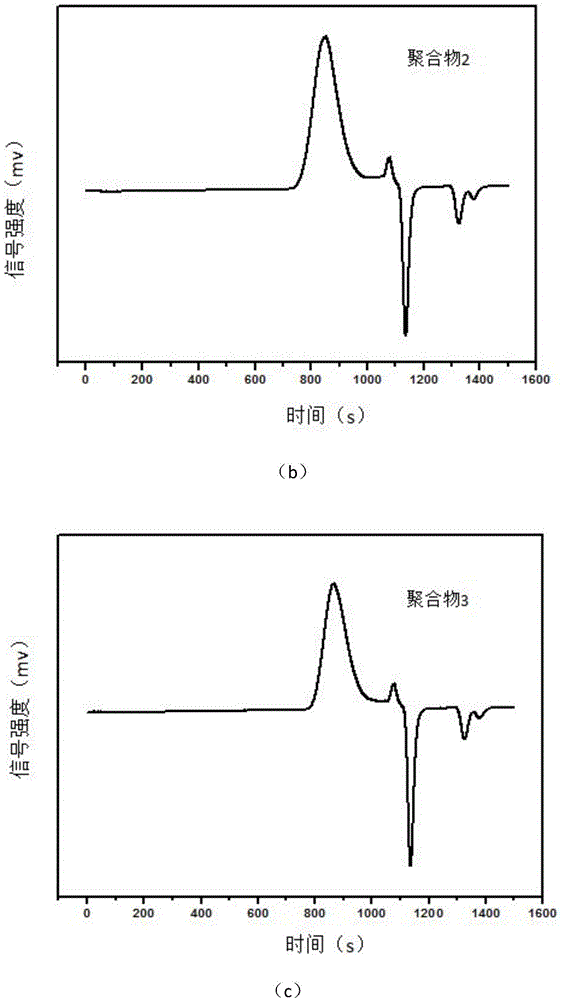

[0037] Add 31.83g (0.1mol) of phenolphthalein, 13.82g (0.1mol) of potassium carbonate, and 4,4'-difluorodifluoride into a dry three-necked flask equipped with mechanical stirring, spherical condenser, nitrogen inlet, water separator and thermometer. Benzophenone 11.24g (0.0515mol), 4,4'-difluorodiphenylphosphine 16.18g (0.0515mol), sulfolane 140ml, xylene 40ml, the solid content of the solution is about 25%. Pour in nitrogen protection, reflux at 200°C for 4 hours, then distill the xylene out, heat up to 220°C, react for 4 hours to obtain a viscous reaction product, slowly pour it into distilled water, in a white strip shape, pass through a crusher After pulverization, it was boiled 10 times with deionized water to remove the solvent and inorganic salt. The final product was dried in an oven at 100°C for 24 hours to obtain polymer 2. The polymer had a phosphorus specific gravity of 2.85% and a number average molecular weight of 10W.

[0038] Dissolve 1.2 g of polymer 2 in 10.8 g ...

Embodiment 3

[0041] Add 31.83g (0.1mol) of phenolphthalein, 13.82g (0.1mol) of potassium carbonate, and 4,4'-difluorodifluoride into a dry three-necked flask equipped with mechanical stirring, spherical condenser, nitrogen inlet, water separator and thermometer. Benzophenone 17.98g (0.0824mol), 4,4'-difluorodiphenylphosphine 6.47g (0.0206mol), 134ml sulfolane, 40ml xylene, the solid content of the solution is about 25%. Pour in nitrogen protection, reflux at 200°C for 4 hours, then distill the xylene out, heat up to 220°C, react for 4 hours to obtain a viscous reaction product, slowly pour it into distilled water, in a white strip shape, pass through a crusher After crushing, boiling with deionized water 10 times to remove the solvent and inorganic salt, the final product was dried in an oven at 100°C for 24 hours to obtain polymer 3 with a phosphorous specific gravity of 1.20% and a number average molecular weight of 6W.

[0042] 1.2 g of polymer 3 was dissolved in 10.8 g of chloroform to pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com