Epoxy anticorrosive paint, and preparation method thereof

A technology of epoxy anti-corrosion coating and epoxy resin, which is applied in the field of coatings, can solve the problems of poor corrosion resistance and high temperature resistance of epoxy resin, poor durability of epoxy resin, and reduced adhesion of epoxy resin, etc., to achieve broaden Application range, increasing thermal stability, improving self-cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

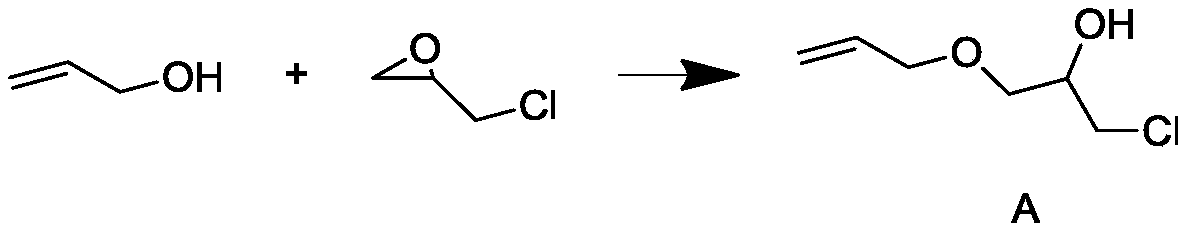

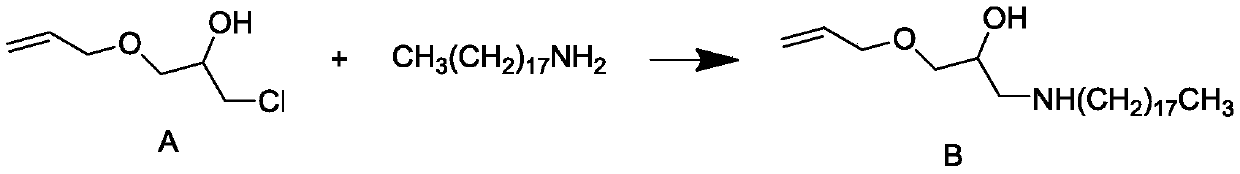

Method used

Image

Examples

preparation example Construction

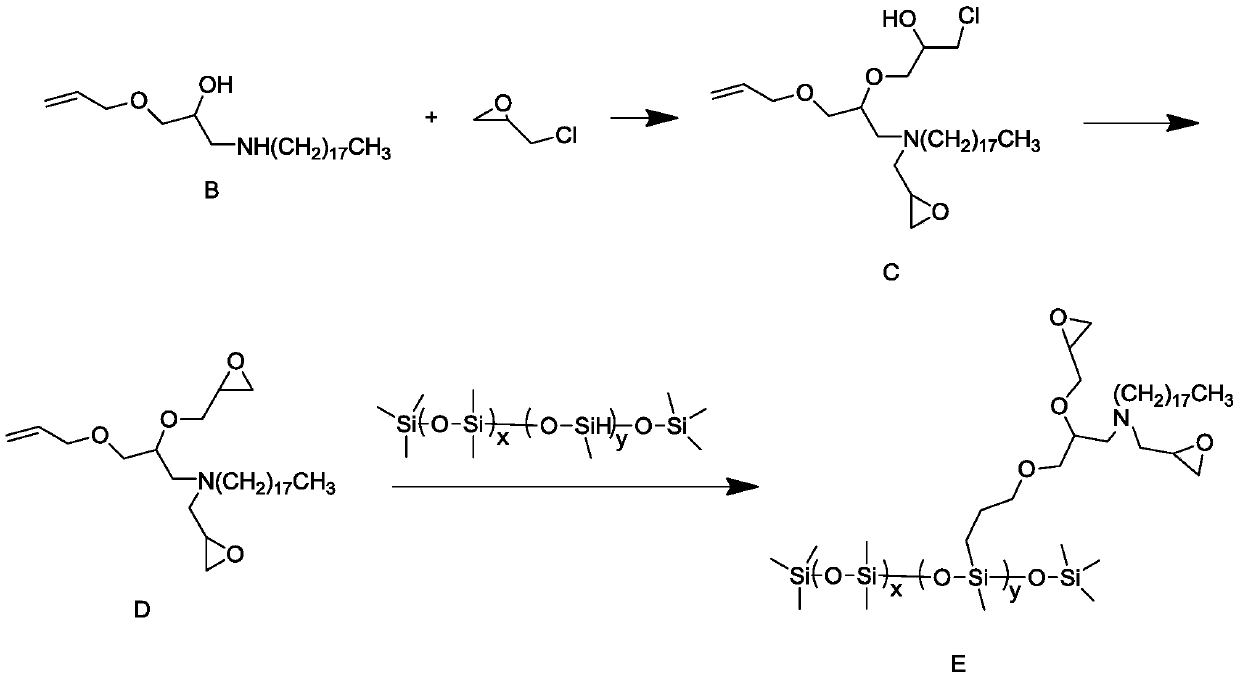

[0047] Preparation of S6 modified epoxy resin

[0048] Add 1kg of epoxy resin to the reactor, then add 200g of modifier E, stir evenly, heat to 100°C, then add 25ml of triethylamine dropwise, add dropwise within 30min, keep warm and continue stirring for 2h, Get modified epoxy resin;

[0049] The structure of possible modified epoxy resins is as follows:

[0050]

[0051] The alcoholic hydroxyl group on the epoxy resin can react with the two epoxy groups on the modifier E, or one molecule of the modifier E can be cross-linked with 2 molecules of the epoxy resin, thereby embedding and connecting the modifier E Branch into epoxy resin;

[0052] The infrared characterization of the modified epoxy resin is as follows: IR(KBr): 3032, 3005 (benzene ring), 2964, 2920 (-CH 2 -, -CH 3 ),1375(-CH 3 ), 1294, 1205 (-C-N), 1180 (-O-Si-C-), 915 (epoxy) cm -1 .

Embodiment 1

[0054] An epoxy anticorrosive coating, comprising raw materials of the following weights: 100g of modified epoxy resin, 80g of pigments and fillers, 5g of dispersant, 15g of film forming aid, 1g of leveling agent, and 1g of defoamer;

[0055] A preparation method of epoxy anticorrosive paint is as follows: put the raw materials of epoxy anticorrosive paint into a mixing tank for premixing for 5 minutes, and then melt and extrude the premix. The extrusion parameters are: one zone 120°C , The second zone 180℃, screw speed 50Hz extruded flakes are put into a ball mill for grinding, the speed of the ball mill is 2200rpm, the ground coarse powder is sieved through a 200-mesh sieve to obtain 10-80 micron fine powder as the final Epoxy anticorrosive coating.

Embodiment 2

[0057] An epoxy anticorrosive coating, comprising raw materials of the following weights: 100g of modified epoxy resin, 120g of pigments and fillers, 2g of dispersant, 20g of film-forming aids, 3g of leveling agent, and 3g of defoamer;

[0058] A preparation method of epoxy anticorrosive paint is as follows: put the raw materials of epoxy anticorrosive paint into a mixing tank for premixing for 10 minutes, and then melt and extrude the premix. The extrusion parameters are: 120°C in one zone , The second zone is 180℃, the screw speed is 50Hz, and the extruded flakes are put into a ball mill for grinding. The speed of the ball mill is 1600rpm. The ground coarse powder is sieved through a 200-mesh sieve to obtain a fine powder of 10-80 microns. Epoxy anticorrosive coating.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com