Patents

Literature

54 results about "Waxy Starch" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Starch from waxy maize differs from regular maize starch in both molecular structure and pasting characteristics. Pastes made from waxy starch are long and cohesive, whereas pastes made from regular maize starch are short and heavy bodied. Waxy maize starch is a major starch component in adhesives used for making bottle labels.

Edible Film

InactiveUS20100240724A1Excellent film forming property and solubility and feelingEasy to prepareBiocideNervous disorderSolubilityHydrolysate

The present invention relates to an edible film composition comprising a waxy starch hydrolysate, a modified starch and a water-soluble polymer, and an edible film comprising the same. The present edible film may not only have an excellent film forming property, solubility and feeling in the oral cavity, but also be easily prepared at low cost, and thus be usefully used as an oral cleanser or a bad breath remover for oral cleansing, and a soluble formulation on tongue for uptake of drug in the oral cavity.

Owner:C L PHARM

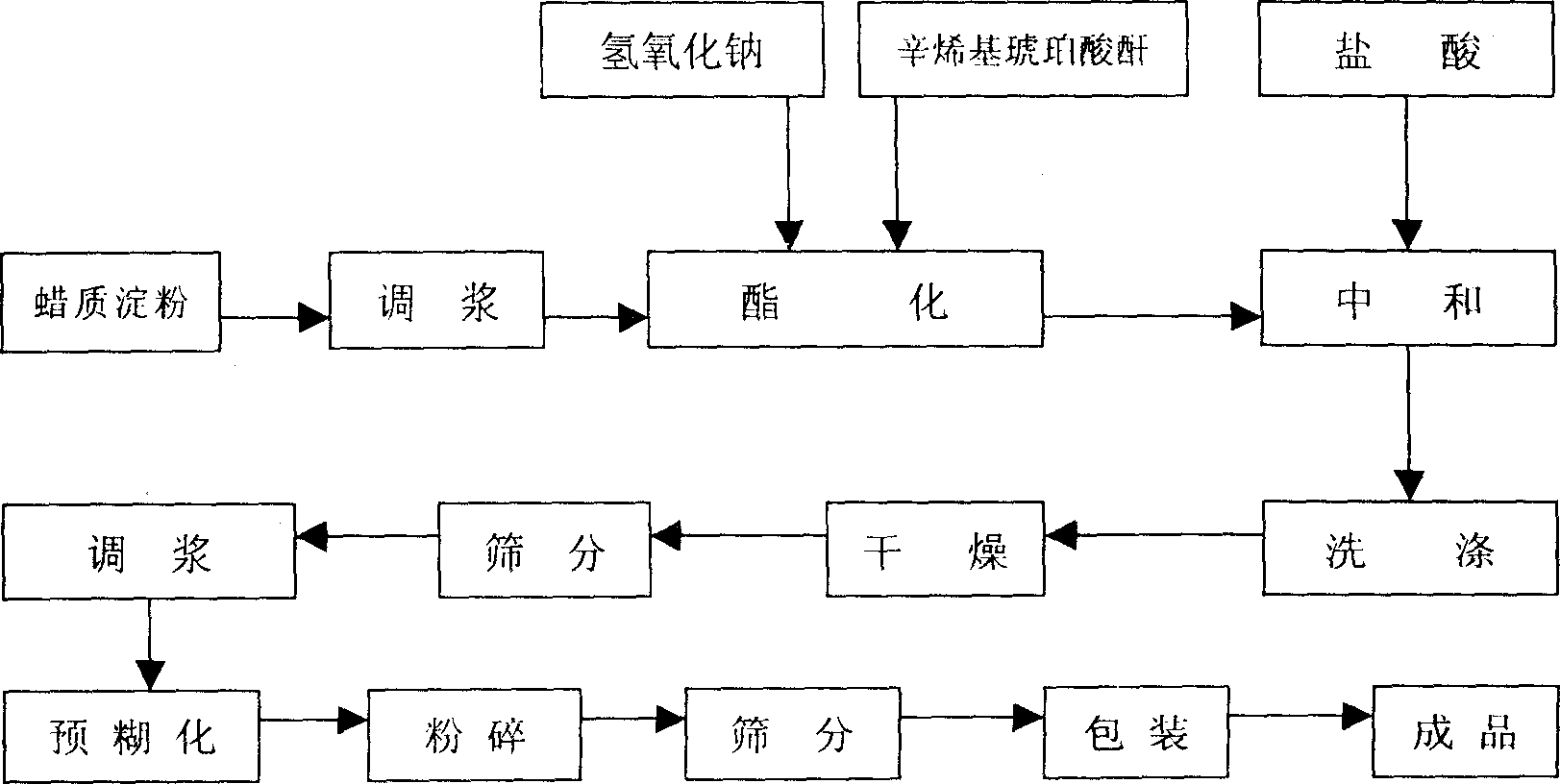

Predextrinization octeneyl succinate starch and its preparation method

InactiveCN1903883AWide variety of sourcesThe process flow is simple and applicableSolubilityOctenyl succinate

The present invention discloses a kind of pregelatinized octalkenyl succinate starch and its preparation method. It is made up by using waxy starch, octalkenyl succinic anhydride, hydrochloric acid and sodium hydroxide as raw material and making said raw materials undergo the processes of mixing paste, esterification, neutralization, washing, drying, screening, mixing paste, pregelatinizing, pulverizing, screening and packaging. Besides, said invention also provides its concrete application range.

Owner:四平帝达变性淀粉有限公司

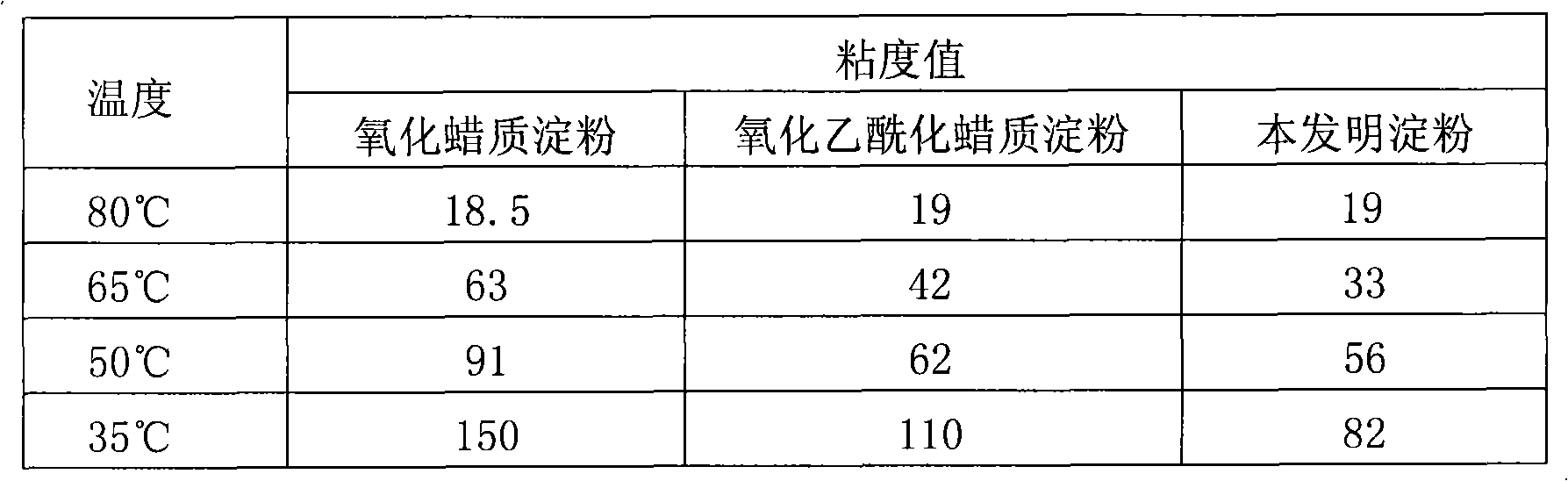

Waxy modified starch, preparation method and application thereof

InactiveCN101676308AGood viscosity stabilityViscosity unchangedWater-repelling agents additionFibre treatmentFreeze thawingSolubility

The invention provides a method for producing multiplex composite modified starch using pure branched chain waxy starch as raw paderial and product obtained using the method and application thereof. The production method of the modified starch is a complex reaction of grafting, cross-linking and oxidizing. The multiplex modified starch has features of good paste viscosity stability, high transparency, strong shear force resistance, high water-solubility, good freezing stability and freeze-thawing stability. The modified starch is a good adhesive and can be widely used in food industry, paper industry and weaving industry, especially suitable for surface glue-applying and coating technology in paper industry and warp sizing technology for weaving industry.

Owner:长春大成特用玉米变性淀粉开发有限公司

Barley cultivar salute

ActiveUS7652202B2Small sizeOther foreign material introduction processesFermentationFiberGenetic Materials

A barley cultivar, designated Salute, is disclosed. The invention relates to the seeds of barley cultivar Salute, to the plants of barley Salute, and to methods for producing a barley plant produced by crossing barley cultivar Salute with itself or another barley variety. The invention also relates to methods for producing a barley plant containing in its genetic material one or more transgenes and to the transgenic barley plants and plant parts produced by those methods. The invention also relates to barley varieties or breeding varieties and plant parts derived from barley cultivar Salute, to methods for producing other barley varieties, lines or plant parts derived from barley cultivar Salute, and to the barley plants, varieties, and their parts derived from the use of those methods. The invention further relates to hybrid barley seeds and plants produced by crossing barley cultivar Salute with another barley cultivar. This invention further relates to methods for developing other barley varieties or breeding lines derived from variety Salute including cell and tissue culture, haploid systems, mutagenesis, and transgenic derived lines. Salute demonstrates a unique combination of traits for the human food market including waxy starch, low cracking upon pearling and increased levels of Beta-glucan fiber and Beta-glucan fiber viscosity.

Owner:HIGHLAND SPECIALTY GRAINS

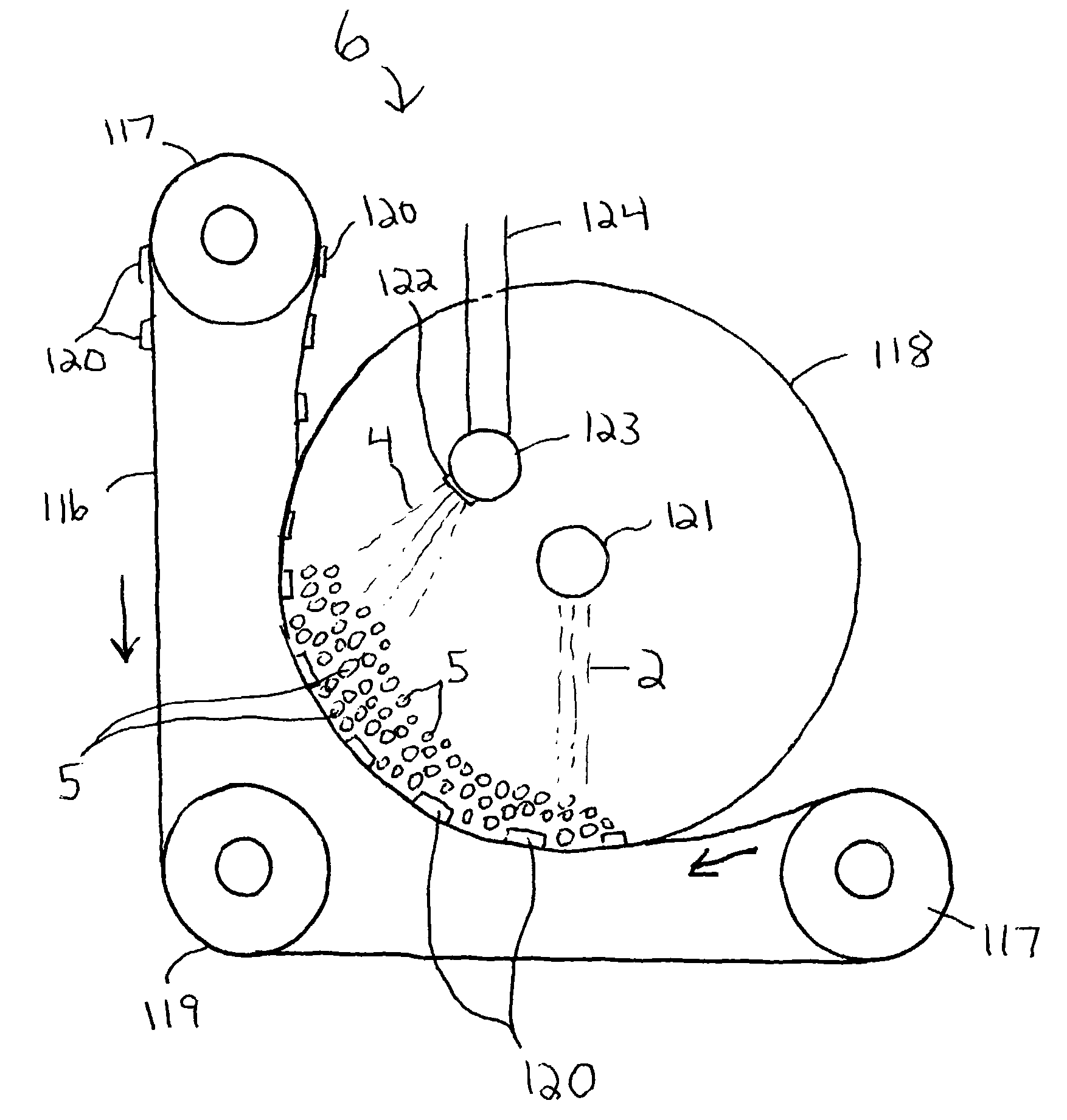

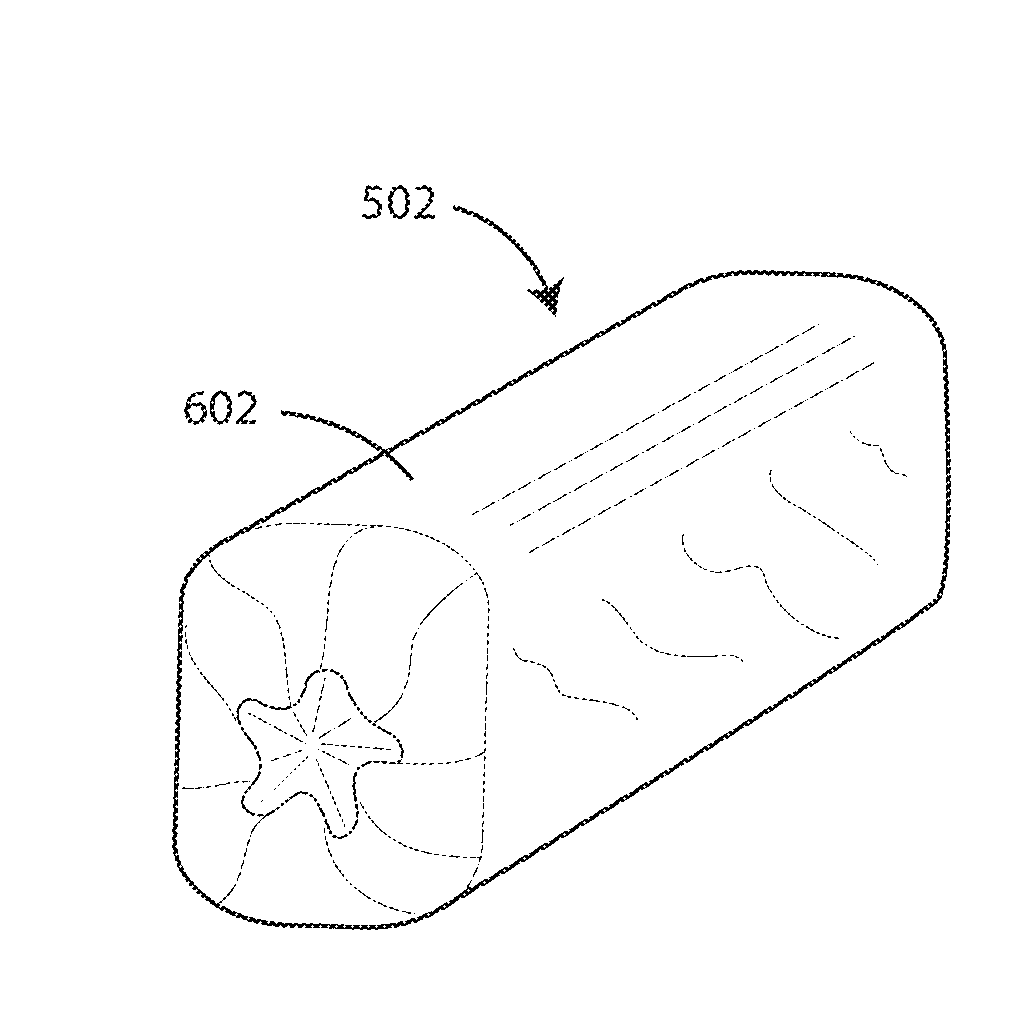

Production of snacks having an expanded, crispy, chip-like textured coating

InactiveUS7867537B2Increase heightReduce absorptionConfectionerySweetmeatsProduction ratePotato starch

A savory or sweet snack having an expanded, crispy, chip-like textured, substantially uniform, homogeneous, cellular coating is obtained by tumbling an edible core material, such as nuts or dried fruit, and alternately applying an aqueous component and a preblended dry mixture on the tumbling edible core material to form a dough coating on the edible core material. The dough-coated core material may be heated by frying or baking to substantially reduce the moisture content of the dough, and to substantially expand the dough. The thick, expanded coating has a substantial amount of wheat yet it possesses a crispy, crunchy texture of a chip, rather than a leavened, mealy or flaky texture. Use of a pregelatinized waxy starch, which is not chemically modified, provides crispness and a high degree of expansion Use of a pure, raw potato starch which is not chemically modified promotes crunchiness and a chip-like texture and reduces oil pick-up or absorption during frying. The tumbling is preferably performed in a continuous belt coating device to achieve high production rates and uniform coating of individual core material pieces without agglomeration or sticking of pieces to each other.

Owner:INTERCONTINENTAL GREAT BRANDS LLC

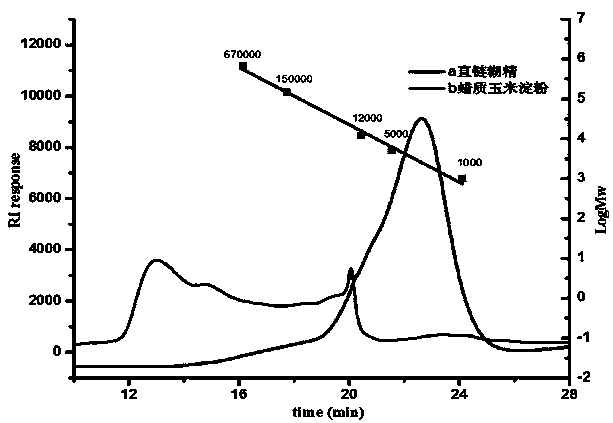

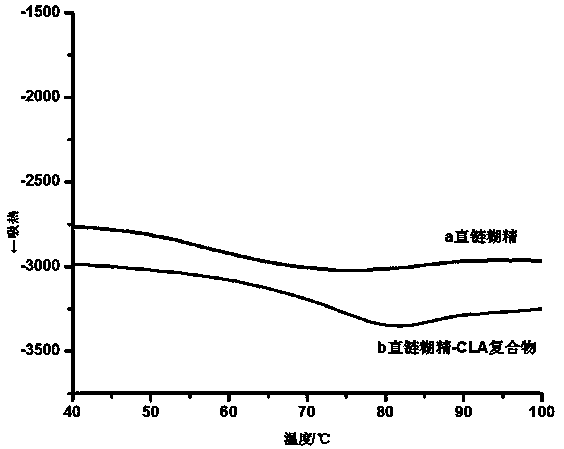

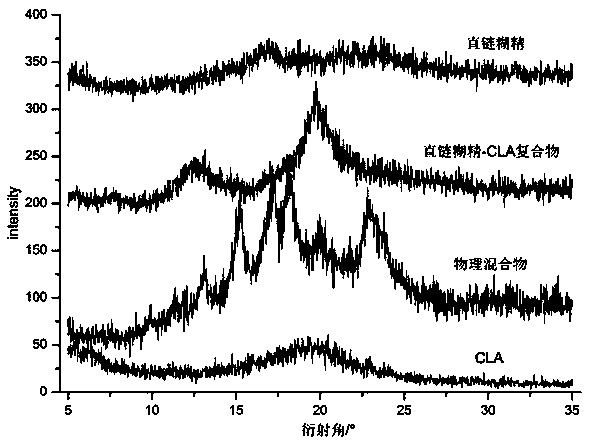

Preparation method of straight chain dextrin embedded conjugated linoleic acid microcapsules

ActiveCN103990424AAvoid Potential ToxicitySmall molecular weightMicroballoon preparationMicrocapsule preparationSolubilityFreeze-drying

A preparation method of straight chain dextrin embedded conjugated linoleic acid microcapsules comprises the following steps: dissolving waxy starch in water, heating for gelatinizing, cooling, adding isoamylase for complete debranching, centrifuging, and freeze-drying to obtain straight chain dextrin powder; and dissolving the straight chain dextrin powder, placing the obtained straight chain dextrin solution at a crystallization temperature, dissolving conjugated linoleic acid (CLA) in a preheated anhydrous ethanol solution, adding the obtained CLA solution into the solution, carrying out heat insulation stirring for a certain time, taking out, cooling to room temperature, centrifuging, washing the obtained precipitate by using an anhydrous ethanol / water mixed solution to remove uncompounded CLA, centrifuging, and carrying out vacuum drying on the finally obtained precipitate to obtain a microcapsule embedding material containing the CLA. The method improves the solubility of the straight chain dextrin and CLA compound, the oxidation stability of the CLA and the bioavailability in an aqueous solution, so the problems of low dissolvability of the straight chain starch compound, and easy automatic oxidation and low bioavailability of the CLA are solved, and the microcapsules can be added to functional nutrition reinforcement foods and staple foods as a nutrition reinforcement agent.

Owner:JIANGNAN UNIV

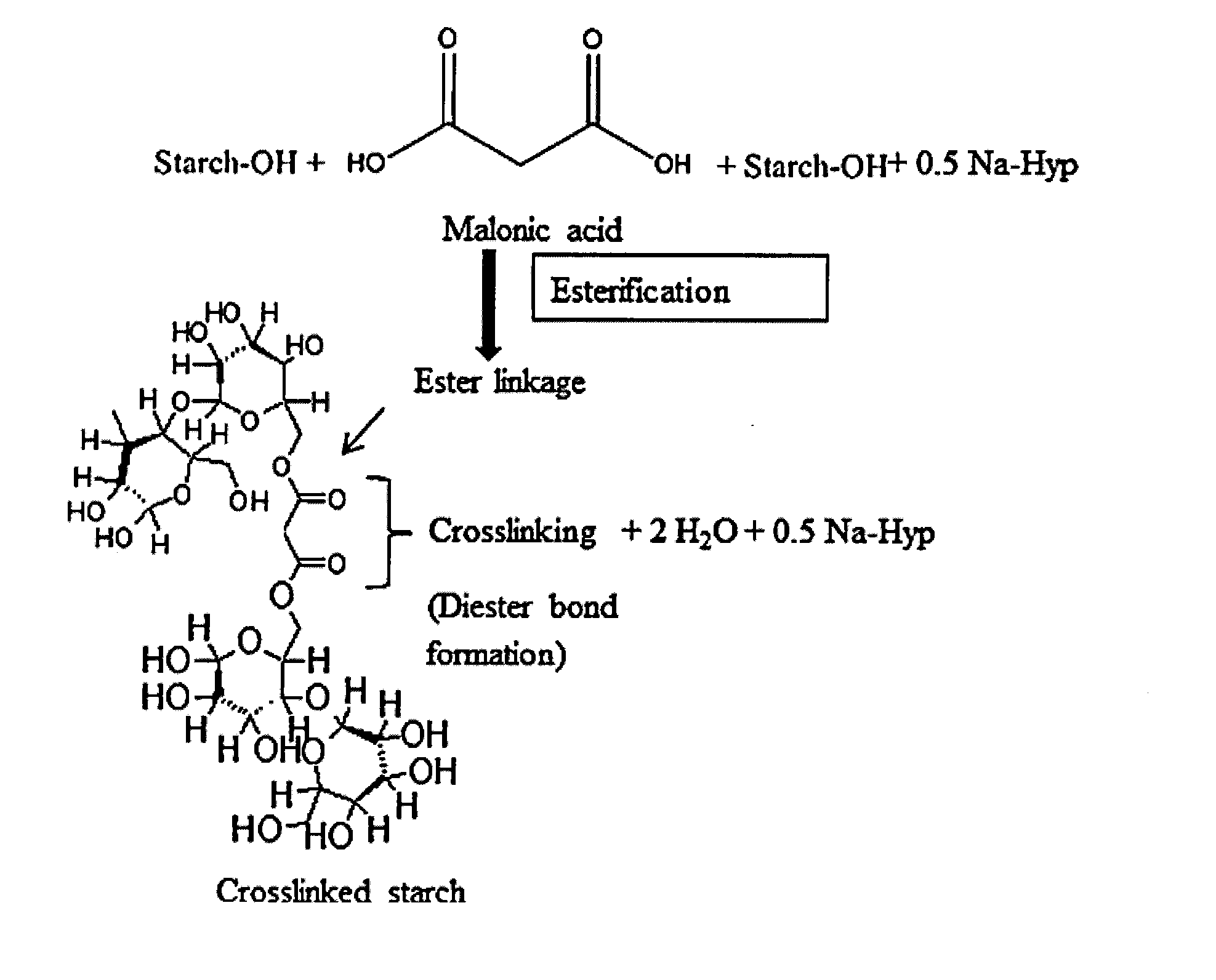

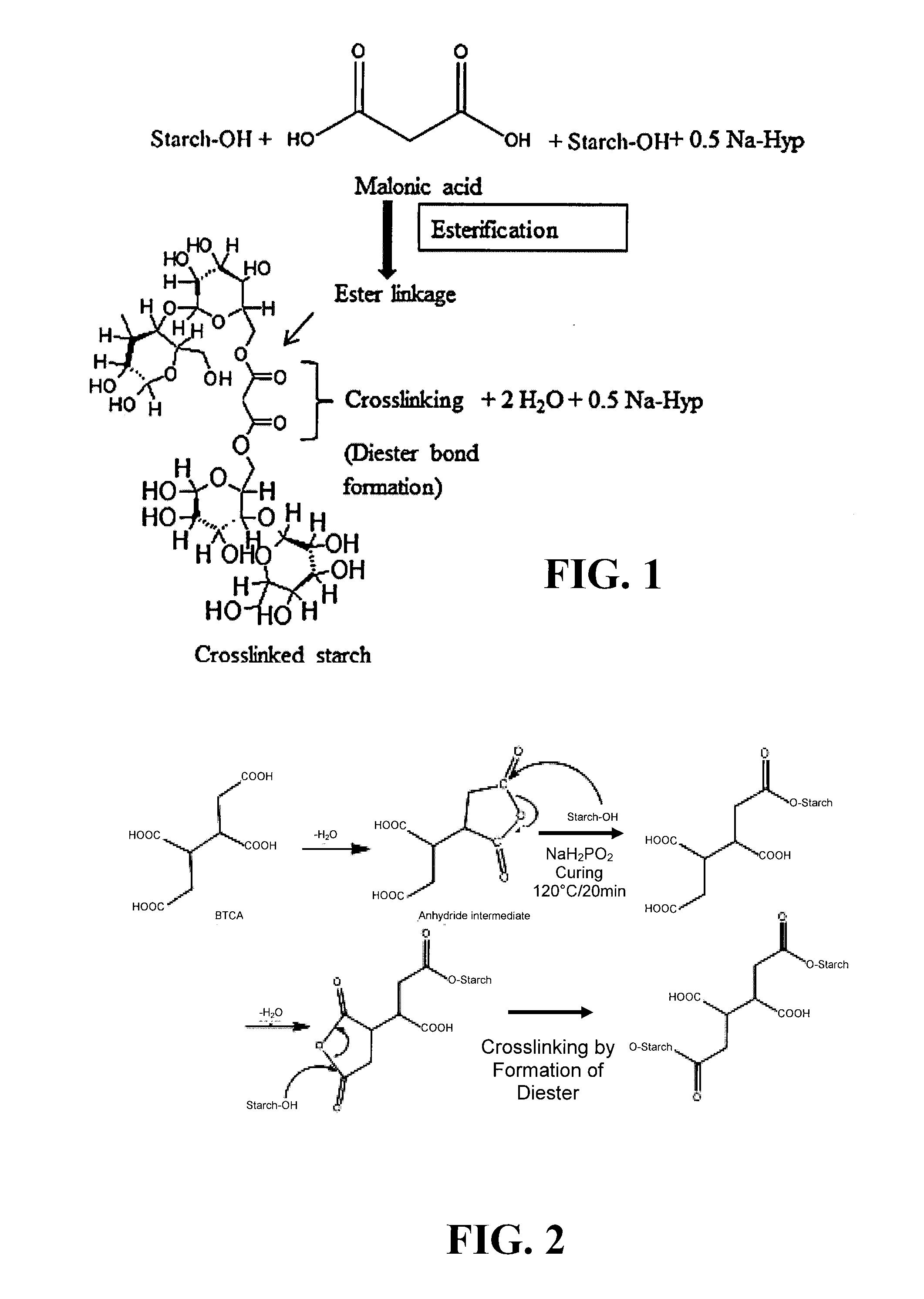

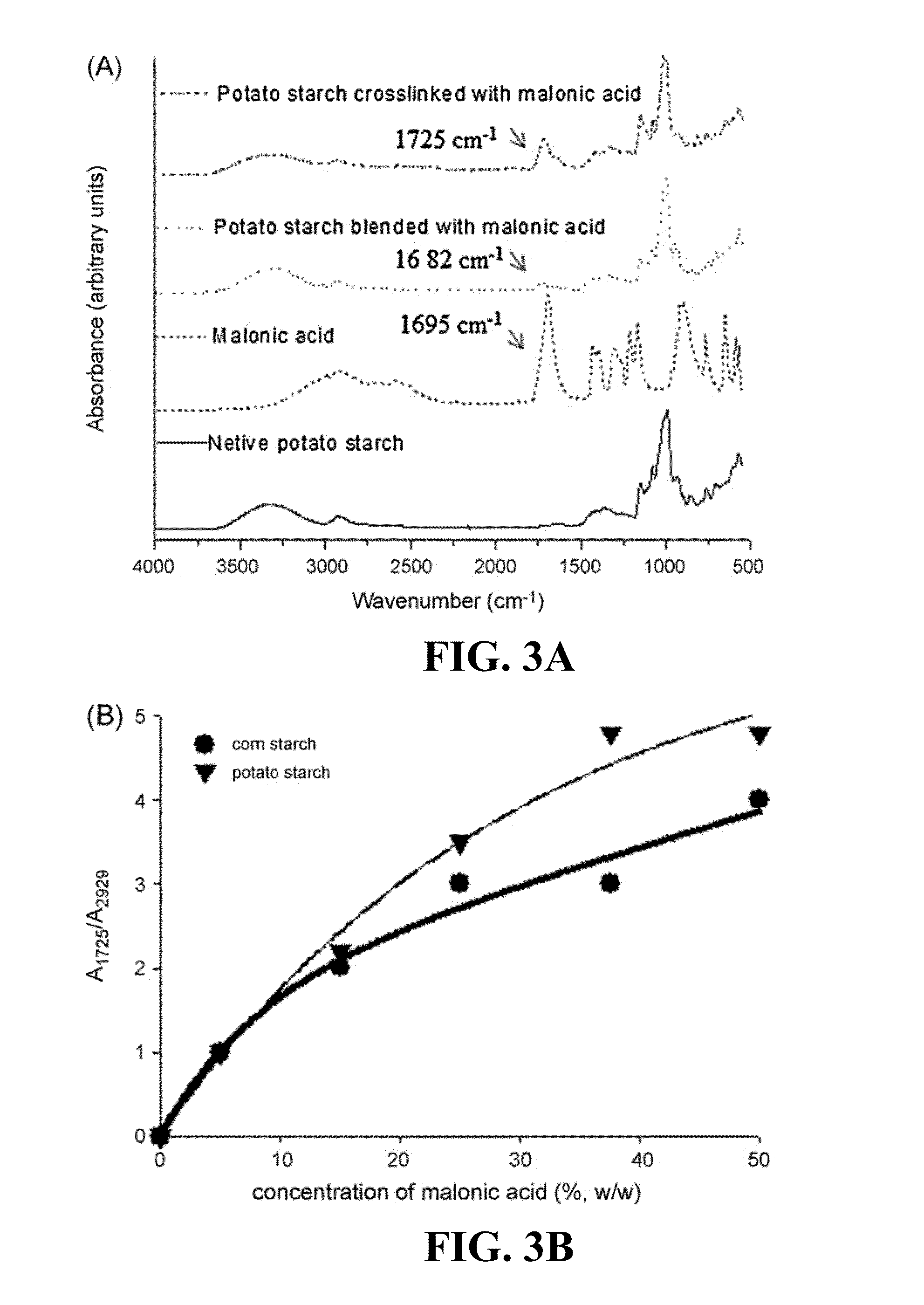

Crosslinked native and waxy starch resin compositions and processes for their manufacture

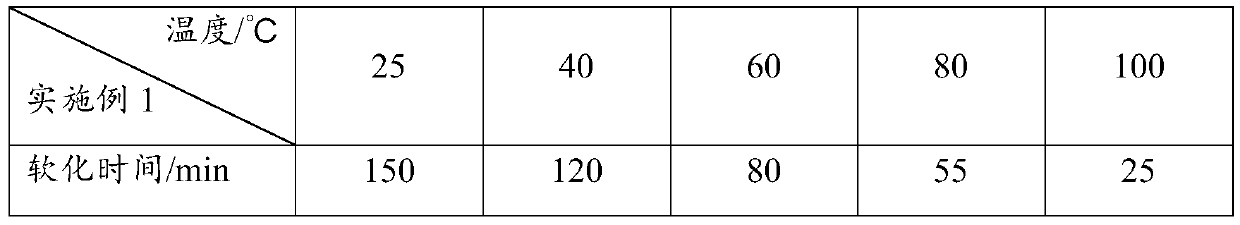

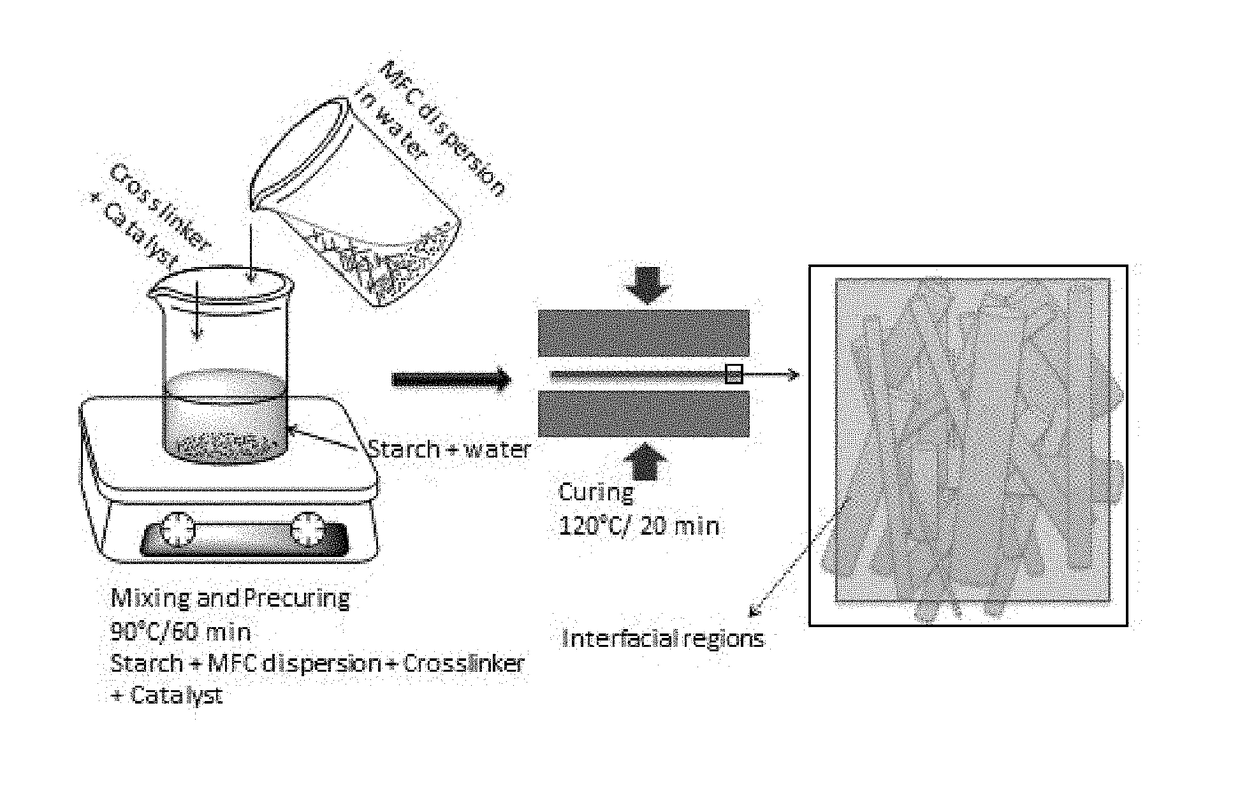

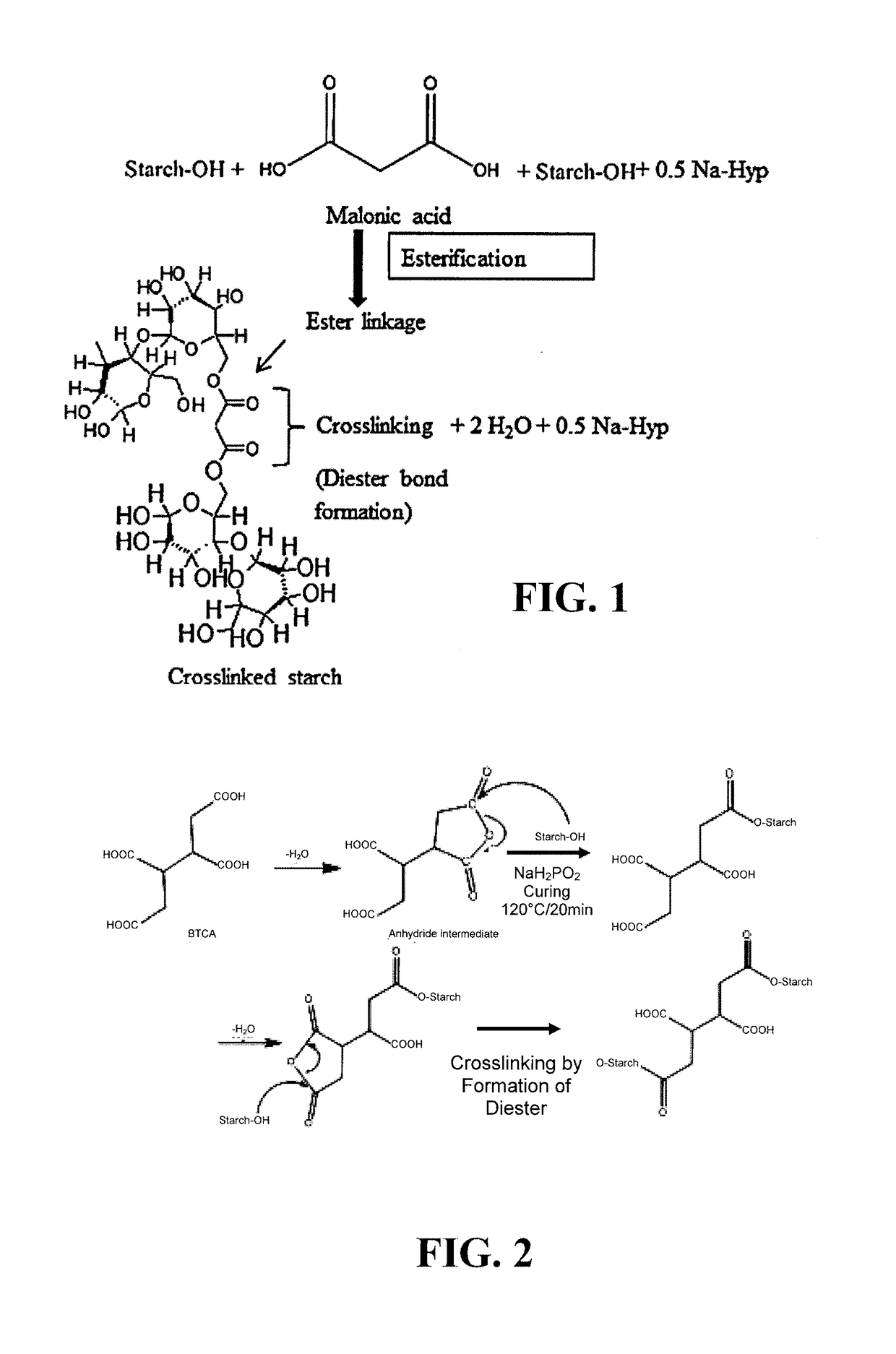

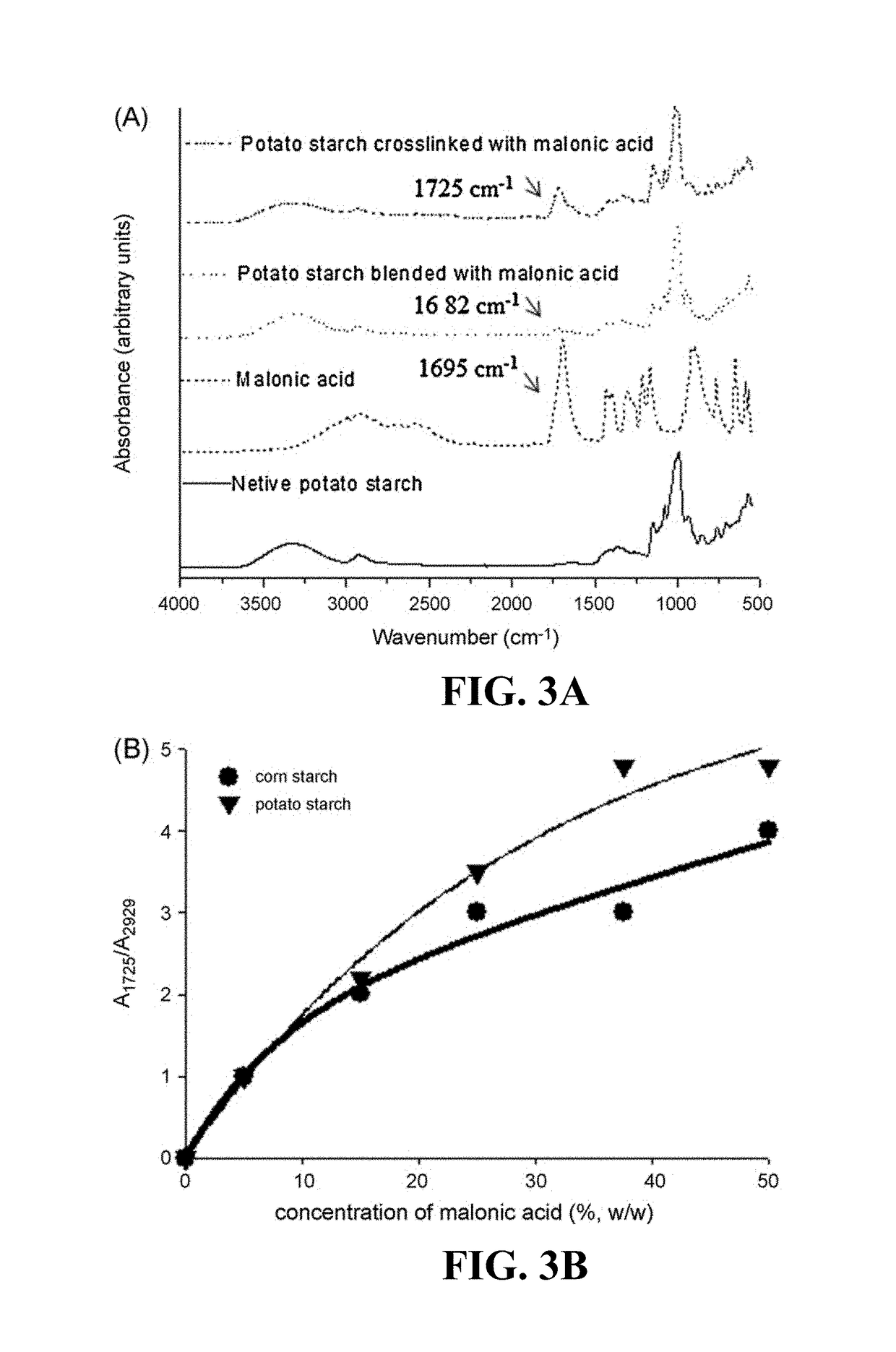

ActiveUS20150203667A1Improve mechanical propertiesLow moisture absorptionCellulose adhesivesCoatingsWater basedCarboxylic acid

The present invention relates to an enhanced starch resin composition, methods of making the enhanced starch resin composition using environmentally benign, water-based processes, and products produced using the enhanced starch resin composition. The enhanced starch resin composition comprises a native starch and / or a waxy starch crosslinked with a multi-functional polycarboxylic acid. The starch resin composition is formed by a water-based reaction comprising using a non-toxic, water-soluble catalyst to catalyze esterification of the native starch and / or the waxy starch with the multi-functional polycarboxylic acid, thereby yielding a crosslinked starch resin composition having at least one enhanced mechanical property and / or reduced moisture absorption as compared to the native starch and / or the waxy starch.

Owner:CORNELL UNIVERSITY

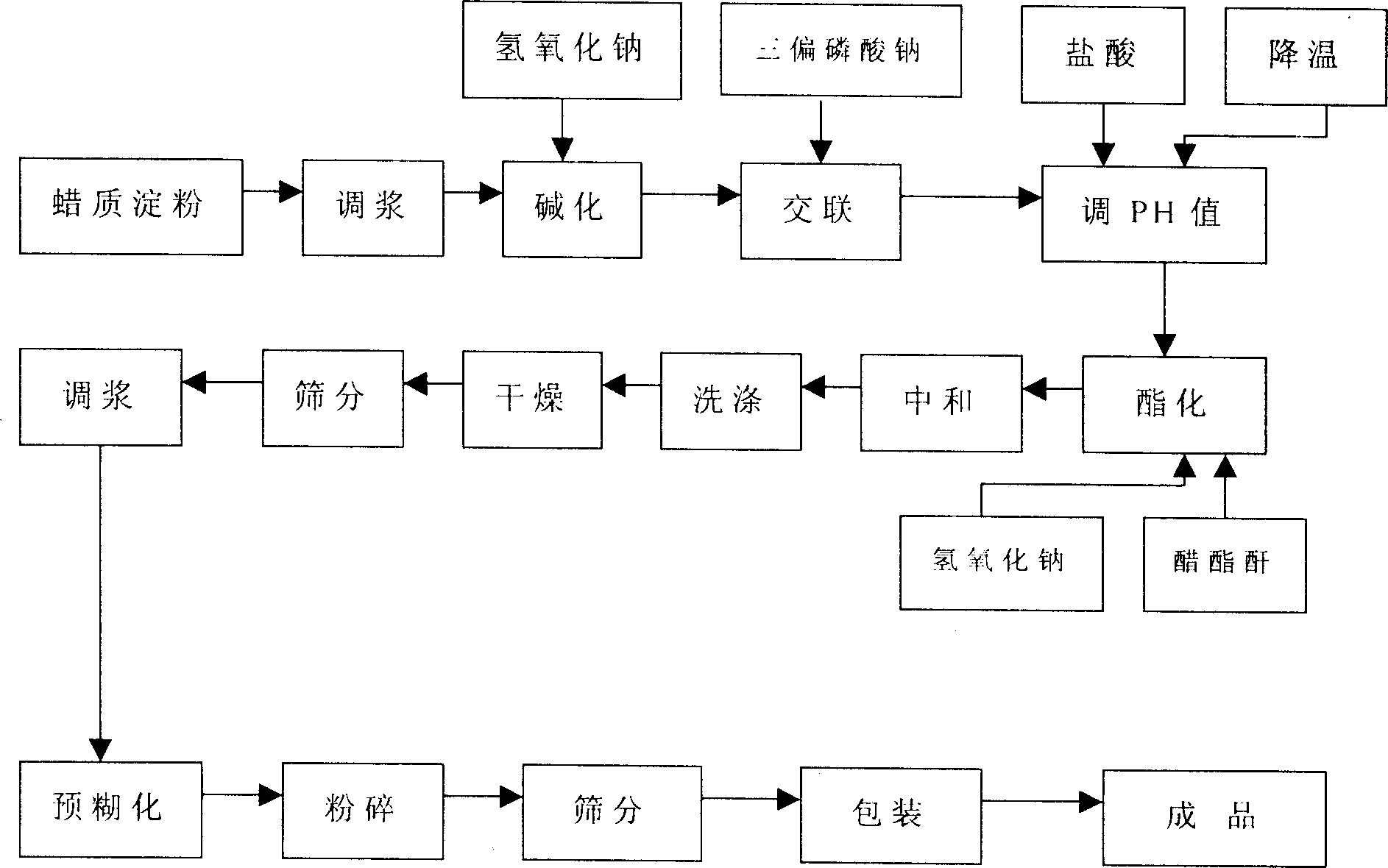

Predextrinization acetylated distarch phosphate and its preparation method

The present invention discloses a kind of pregelatinized acetylated distarch phosphate and its preparation method. It is made up by using water as medium and using waxy starch, acetic anhydride, hydrochloric acid, sodium hydroxide and sodium trimetaphosphate as raw material through 13 processes of mixing paste, alkalization, cross-linking, esterification, neutralization, washing, drying, screening, mixing paste, pregelatinizing, pulverizing, screening and packaging. It can be used as thickening and stabilizing agent in the flavouring material and snack food, etc.

Owner:四平帝达变性淀粉有限公司

Method for efficiently preparing starch nanocrystalline

InactiveCN109265570AReduce distributionSmall particle size distributionFermentationAlcoholCentrifugation

The invention provides a method for efficiently preparing starch nanocrystalline, and belongs to the field of starch processing. The method combines the techniques of waxy starch debranching to prepare straight-chain dextrin, the molecular weight distribution of straight-chain dextrin is narrowed through classification, self-assembly of straight-chain dextrin is accelerated by combining polyethylene glycol precipitation to form starch nanocrystalline, and the starch nanocrystalline is prepared. The method mainly comprises the steps that waxy starch is dextrinized, pullulanase is debranched toobtain a straight-chain dextrin solution, ethyl alcohol is added while stirring is conducted till the volume ratio of the straight-chain dextrin solution to ethyl alcohol is 3 to 1, the mixed solutionis continuously stirred for 10 min and standing for 1 h at the temperature of 4 DEG C, centrifugation is conducted, and the sediment is removed; ethyl alcohol is slowly added continuously in the supernatant liquid till the volume ratio of straight-chain dextrin to ethyl alcohol is 1 to 3, stirring is conducted continuously for 10 min, the obtained product is standing for 1 h at the temperature of4 DEG C, centrifugation is conducted, and straight-chain dextrin sediment is obtained; straight-chain dextrin is dispersed in water, the straight-chain dextrin solution with the concentration being 4.0-8.0% is prepared, polyethylene glycol is added in the straight-chain dextrin solution at the proportion of 40.0-50.0 g to 100 mL, the mixture is heated and stirred till polyethylene glycol is completely dissolved, the product is cooled to be 4 DEG C and standing for 1-2 h at the temperature of 4 DEG C, centrifugation is conducted to obtain the sediment, the residual polyethylene glycol is washed through trichloromethane, the product is blasted and dried for 5 min at the temperature of 40 DEG C, and the starch nanocrystalline is obtained.

Owner:NANCHANG UNIV

Starch-based steady-state vegetable oil compound and preparation method thereof

ActiveCN111990477AMild conditionsSimple and fast operationLipidic food ingredientsFood shapingVegetable oilPorous starch

The invention discloses a starch-based steady-state vegetable oil compound and a preparation method thereof. The preparation method comprises the following steps: (1), adding waxy starch with the molecular weight of 6000-10000 kda into water, and performing heating and stirring for complete gelatinizing to obtain a solution A; (2) adding gelatin into water, and performing heating for dissolving toobtain a solution B; (3) adding the solution A into the solution B, performing cooling and uniform stirring, adding a stabilizer, and performing shearing and homogenizing to obtain a water-in-water Pickering emulsion; (4) cooling the Pickering emulsion to swell the solution A and the solution B to form hydrogel, performing dialyzing in water to remove gelatin, and performing precipitating and drying with ethanol to obtain porous starch; and (5) mixing the vegetable oil with the porous starch, performing quick stirring, and carrying out vacuum drying to obtain the starch-based steady-state vegetable oil compound. The slow release of the vegetable oil is realized, the bioavailability is improved, and the oxidation reaction is effectively inhibited.

Owner:SOUTH CHINA UNIV OF TECH +1

Starch-based gluten-free baked foodstuffs

InactiveUS20150342201A1Extended shelf lifeProtein composition from fishDough treatmentPotato starchWaxy Starch

A composition useful as the principal component in a baked foodstuff is provided. The composition comprises an etherified, non-waxy starch selected from the group consisting of tapioca starch, corn starch, and mixtures thereof, and a native starch selected from the group consisting of corn starch, potato starch, and mixtures thereof. Also provided are compositions useful for preparing baked foodstuffs containing the principal component described above and additionally a minor amount of a non-gluten protein, and a minor amount of a hydrocolloid, and baked foodstuffs prepared by baking such compositions. The baked foodstuffs exhibit extended shelf-life without staling of the baked foodstuff by reason of the use of the compositions described above.

Owner:CORN PROD DEV INC

Expansion of Extruded Cereals with Good Source of Fiber

A cereal composition comprising a waxy starch in an amount from about 5 to about 15% by weight of the total composition and a cereal mixture comprising a fiber source in an amount from about 1 to about 15% by weight of the total composition. The cereal composition is mixed with water and expanded by extrusion to form a high-fiber cereal product. Also, a method of producing a high fiber expanded cereal product comprising the step of combining a waxy starch in an amount from about 5 to about 15% by weight of the total composition and a cereal mixture comprising a fiber source in an amount from about 1 to about 15% by weight of the total composition to form a total cereal composition. The total cereal composition is mixed with water and extruded to form an expanded cereal product.

Owner:THE QUAKER OATS CO

Method for processing artificial crab meat

The invention discloses a method for processing artificial crab meat. Due to the utilization of the method, the artificial crab meat which has delicious taste and good mouthfeel, and can enable the appearance, the flavor and the nutrition to approach natural crab meat. The invention is realized through the following technical scheme: the artificial crab meat is processed by the following raw materials by weight percent: 50% of minced fillet, 4% of potato starch, 2% of waxy starch, 15% of egg protein, 2% of crab meat, 1% of crab style spice, 1% of monosodium glutamate and 25% of common salt. The minced fillet and various ingredients are uniformly stirred, fully blended into pulp and poured into a rectangular metal box, the color of crab roe or the crab meat is colored on the top surface and the bottom surface of the rectangular metal box, then the rectangular metal box is put into a pot for stewing, gelatinization is carried out for about 60min at the temperature of 35-45 DEG C, and the stewing is finally carried out for about 40min for forming at the high temperature of 90-95 DEG C. Then the product is cut into threads, the threads are centralized into a beam, compressed and adhered tightly, the color of the crab roe or the crab meat is further colored on the surface, and sterilization is further carried out for 10min at the high temperature of 90 DEG C.

Owner:韦有照

Amino Acid And Protein Hydrolysate Based Formulas With A Stable Emulsion System

InactiveUS20140242216A1Provide supportMilk preparationVitamin food ingredientsMonoglycerideSuccinic acid

The present disclosure relates in part to an emulsion system comprising a waxy starch. The emulsion system is useful, in some embodiments, for incorporation into infant formulas comprising protein equivalent sources, such as formulas designed for individuals with certain protein allergies. Thus, in certain embodiments, the present disclosure relates to a nutritional composition comprising a protein equivalent source comprising a hydrolyzed protein, amino acids, or a mixture thereof, a fat source, a carbohydrate source, and an emulsifier system comprising a waxy starch. The emulsifier system may further include citric acid esters of mono- and di-glycerides or an octenyl succinic acid-modified starch, or both.

Owner:MEAD JOHNSON NUTRITION

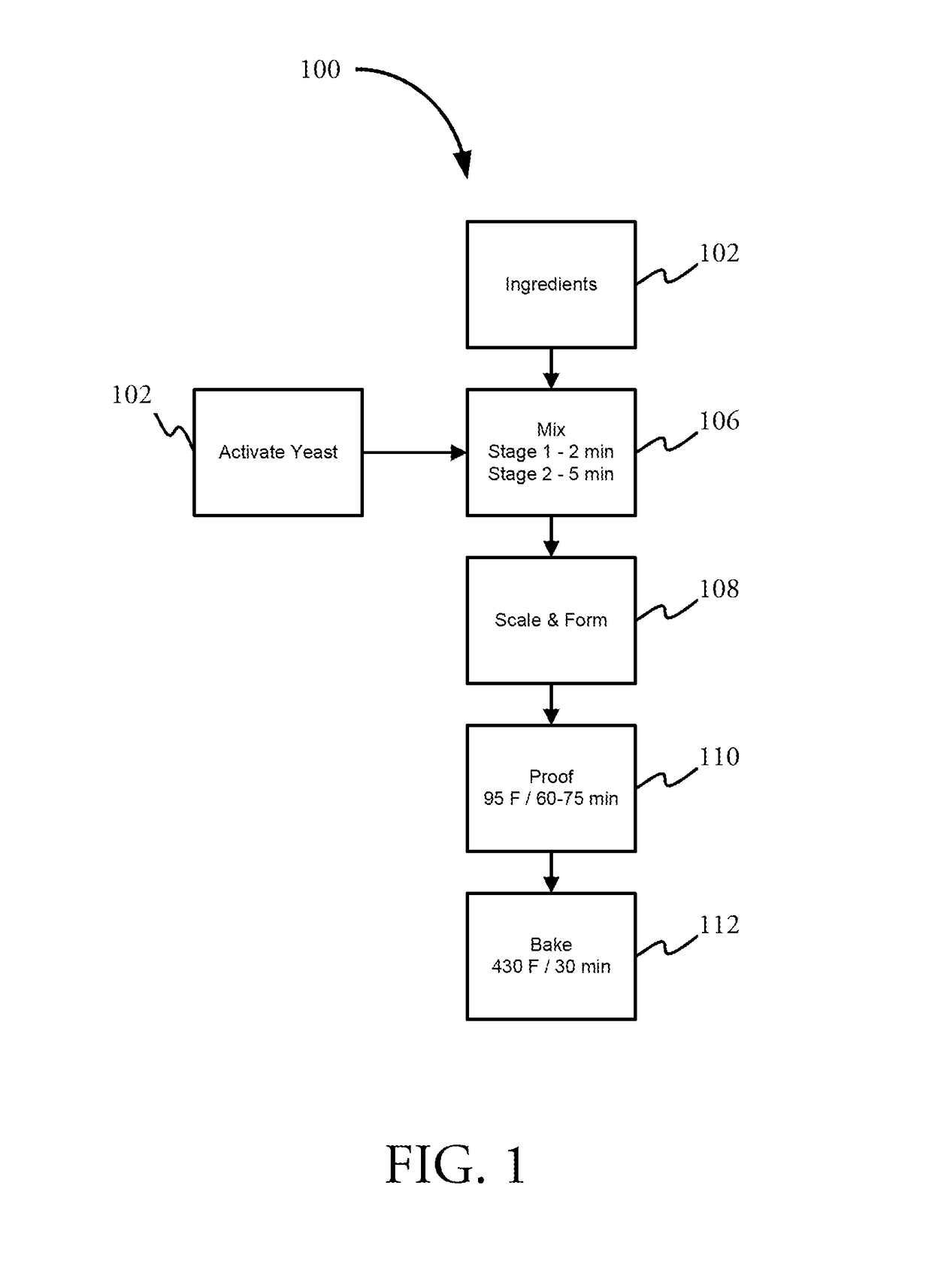

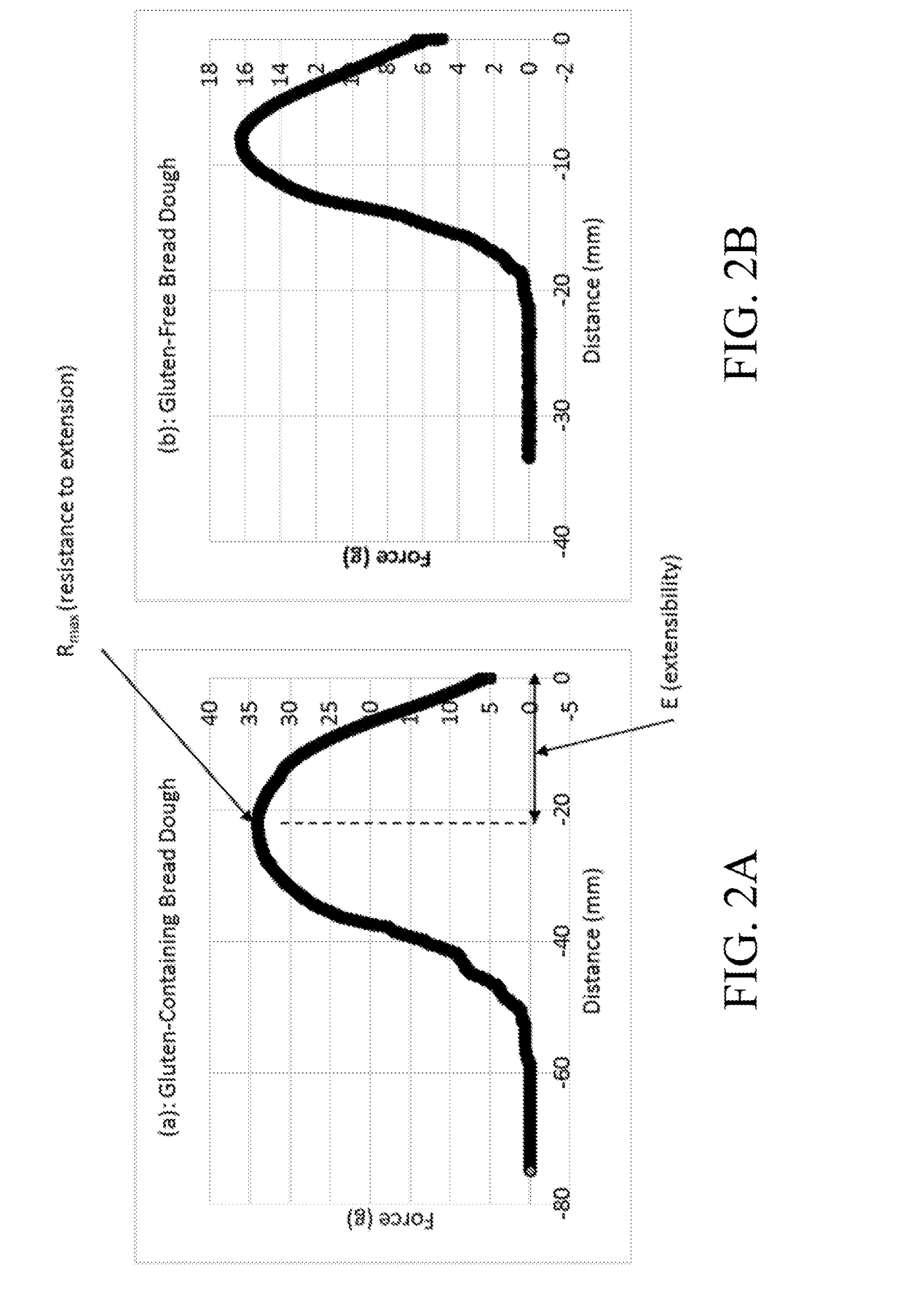

Gluten-free compositions and methods for producing shelf-stable breads and other bakery products

Embodiments herein include gluten-free baked products such as breads gluten-free flour formulations, and related methods. In an embodiment, a bread flour substitute composition is included having a starch blend and a hydrocolloid blend. The starch blend can include a native starch with 20-30% amylose content, a native waxy starch with 0-1% amylose content, and a cross-linked starch. The hydrocolloid blend can include hydroxypropyl methylcellulose (HPMC) and psyllium fiber. The composition can include between 0 and 20 ppm gluten. Other embodiments are also included herein.

Owner:CAMPBELL SOUP COMPANY

Barley cultivar ‘YU599-012’

ActiveUS7897851B2Small sizeVector-based foreign material introductionPlant genotype modificationFiberHordeum vulgare

A barley cultivar, designated YU599-012, is disclosed. The invention relates to the seeds of barley cultivar YU599-012, to the plants of barley YU599-012, and to methods for producing a barley plant produced by crossing barley cultivar YU599-012 with itself or another barley variety. The invention also relates to methods for producing a barley plant containing in its genetic material one or more transgenes and to the transgenic barley plants and plant parts produced by those methods. The invention also relates to barley varieties or breeding varieties and plant parts derived from barley cultivar YU599-012, to methods for producing other barley varieties, lines or plant parts derived from barley cultivar YU599-012, and to the barley plants, varieties, and their parts derived from the use of those methods. The invention further relates to hybrid barley seeds and plants produced by crossing barley cultivar YU599-012 with another barley cultivar. This invention further relates to methods for developing other barley varieties or breeding lines derived from variety YU599-012 including cell and tissue culture, haploid systems, mutagenesis, and transgenic derived lines. YU599-012 demonstrates a unique combination of traits for the human food market including waxy starch, hulless seed and increased levels of Beta-glucan fiber and Beta-glucan fiber viscosity.

Owner:HIGHLAND SPECIALTY GRAINS

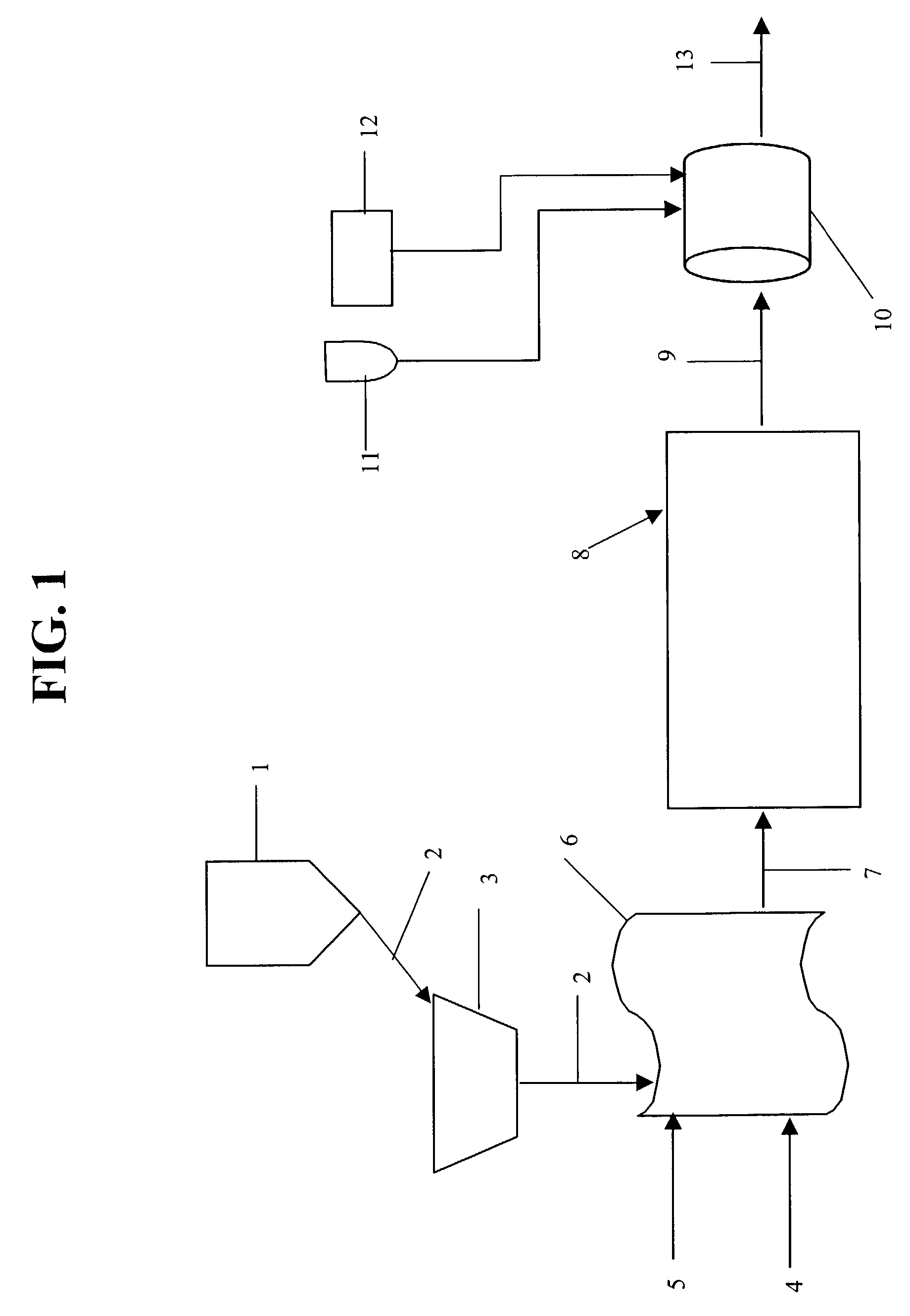

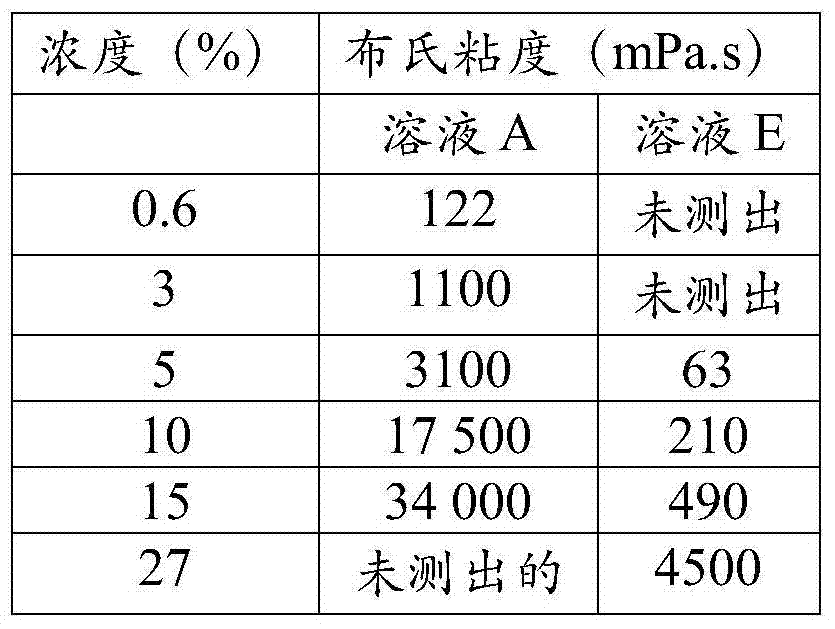

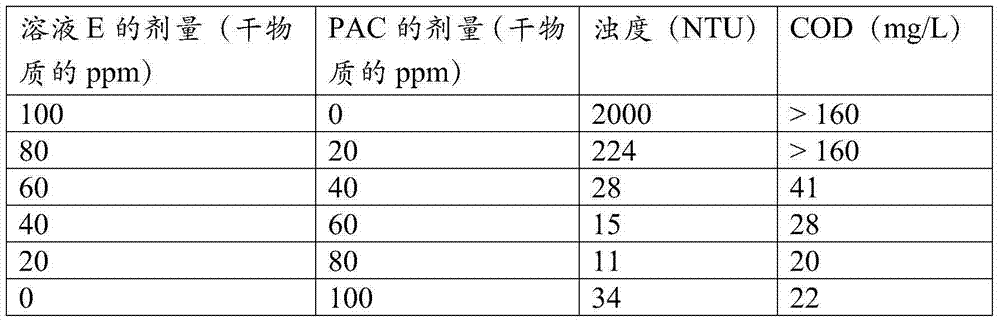

Potabilization process

InactiveCN104781196ALess quantityResidual limitWaste water treatment from plant processingWater/sewage treatment by flocculation/precipitationFlocculationSubject matter

The subject matter of the invention is a process for potabilization of an aqueous solution containing solids in suspension, comprising a coagulation-flocculation step, characterized in that said step comprises: a) a step of adding coagulants to the aqueous solution to be treated; b) a step of stirring the aqueous solution to which coagulants were thus added; c) a step of separating the coagulated solids by settling out or flotation; d) a step of recovering purified water; and in which the coagulants added in step a) comprise metal salts chosen from ferric salts and aluminium salts, and also a liquid starchy composition comprising a cationic waxy starch, said cationic starch having, when it is placed in the form of an aqueous composition, a viscosity, measured according to a test A, greater than 100 mPa.s and less than 1000 mPa.s, this test A consisting in adjusting the dry weight of cationic waxy starch of the aqueous composition to 10% and then measuring the Brookfield viscosity at 25°C of the resulting composition.

Owner:ROQUETTE FRERES SA

Barley Cultivar BZ493-46e

ActiveUS20100218268A1Reduced kernel sizeSmall sizeOther foreign material introduction processesFermentationFiberHordeum vulgare

A barley cultivar, designated BZ493-46e, is disclosed. The invention relates to the seeds of barley cultivar BZ493-46e, to the plants of barley BZ493-46e, and to methods for producing a barley plant produced by crossing barley cultivar BZ493-46e with itself or another barley variety. The invention also relates to methods for producing a barley plant containing in its genetic material one or more transgenes and to the transgenic barley plants and plant parts produced by those methods. The invention also relates to barley varieties or breeding varieties and plant parts derived from barley cultivar BZ493-46e, to methods for producing other barley varieties, lines or plant parts derived from barley cultivar BZ493-46e, and to the barley plants, varieties, and their parts derived from the use of those methods. The invention further relates to hybrid barley seeds and plants produced by crossing barley cultivar BZ493-46e with another barley cultivar. This invention further relates to methods for developing other barley varieties or breeding lines derived from variety BZ493-46e including cell and tissue culture, haploid systems, mutagenesis, and transgenic derived lines. BZ493-46e demonstrates a unique combination of traits for the human food market including waxy starch, hulless seed and increased levels of Beta-glucan fiber.

Owner:MONSANTO TECH LLC

Environment-friendly modified starch for wallpaper adhesive and method for preparing environment-friendly modified starch

The invention provides environment-friendly modified starch for wallpaper adhesive and a method for preparing the environment-friendly modified starch. The environment-friendly modified starch for thewallpaper adhesive mainly comprises starch raw materials and addition raw materials. The starch raw materials mainly include waxy starch, cassava starch and wheat starch, and the addition raw materials mainly include expansion inhibitors, etherifying agents and cross-linking agents. The method includes preparing the modified starch for the wallpaper adhesive with different degrees of viscosity from starch by means of etherifying and cross-linking. The environment-friendly modified starch and the method have the advantages that paste liquid of the environment-friendly modified starch is high in viscosity, good freeze-thaw property effects can be realized, and the environment-friendly modified starch is high in adhesive property; the environment-friendly modified starch is environmentally friendly and is free of harmful substances or peculiar smell; processes and equipment for producing the environment-friendly modified starch are simple and are low in production cost.

Owner:山东福洋生物科技股份有限公司

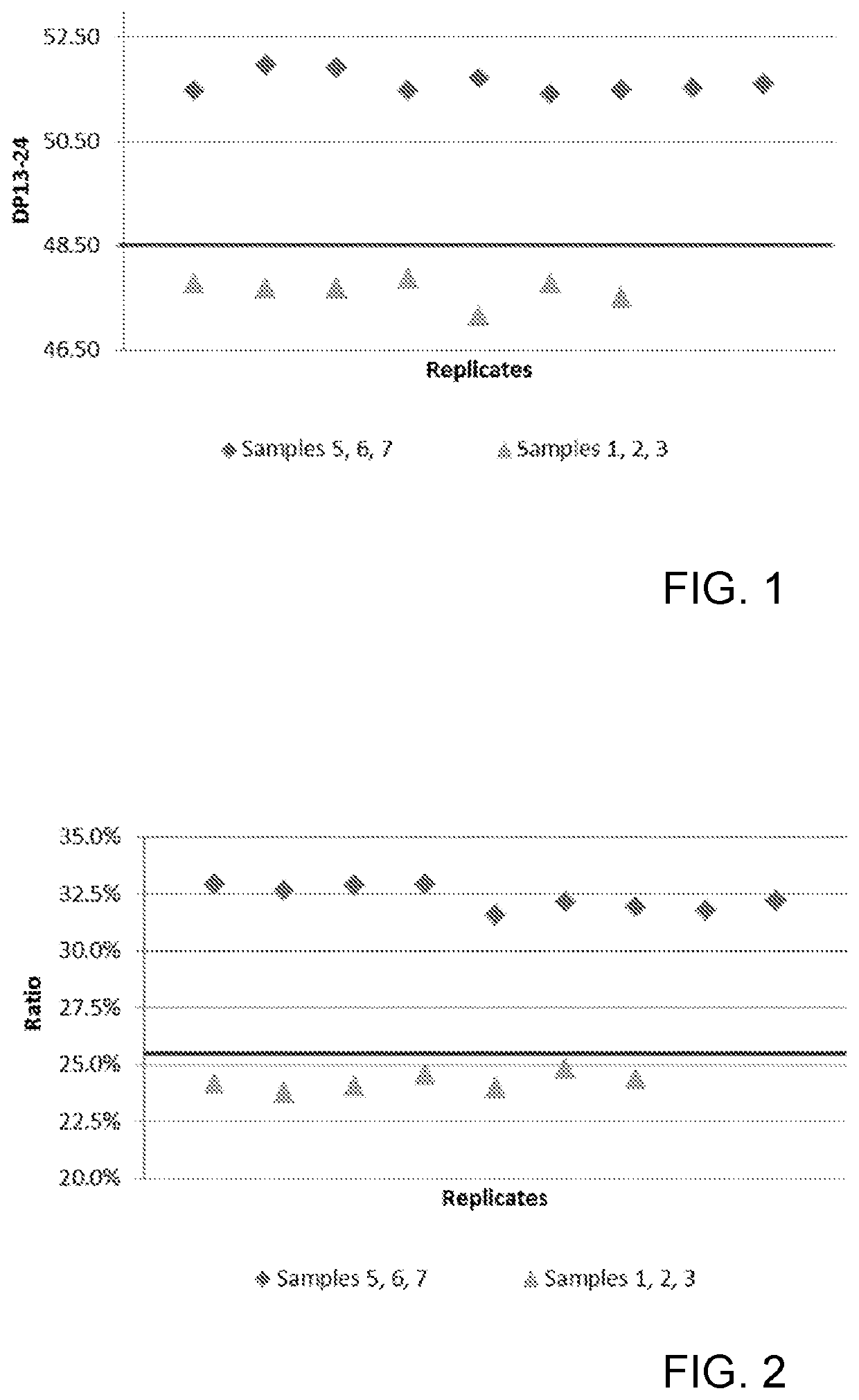

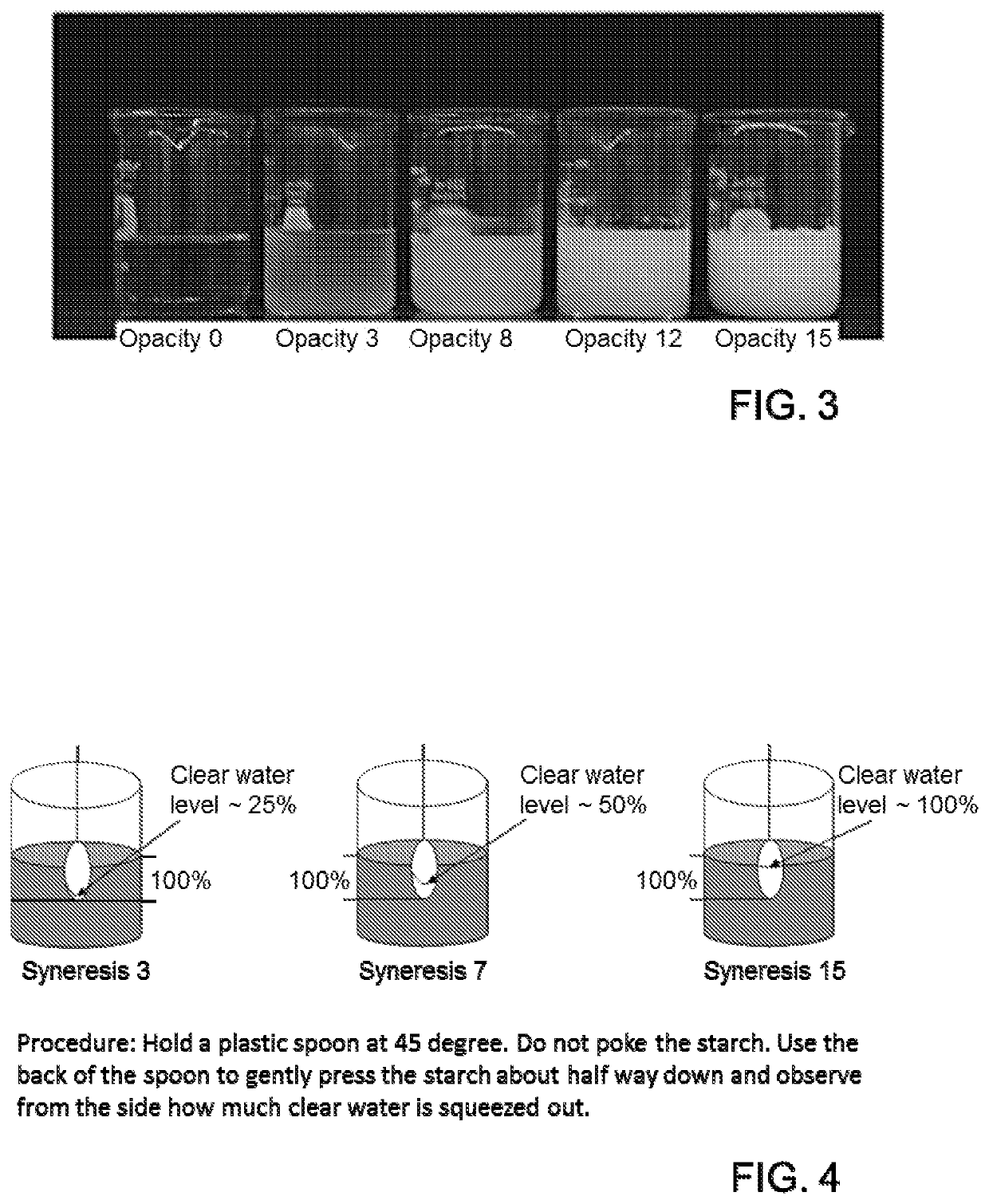

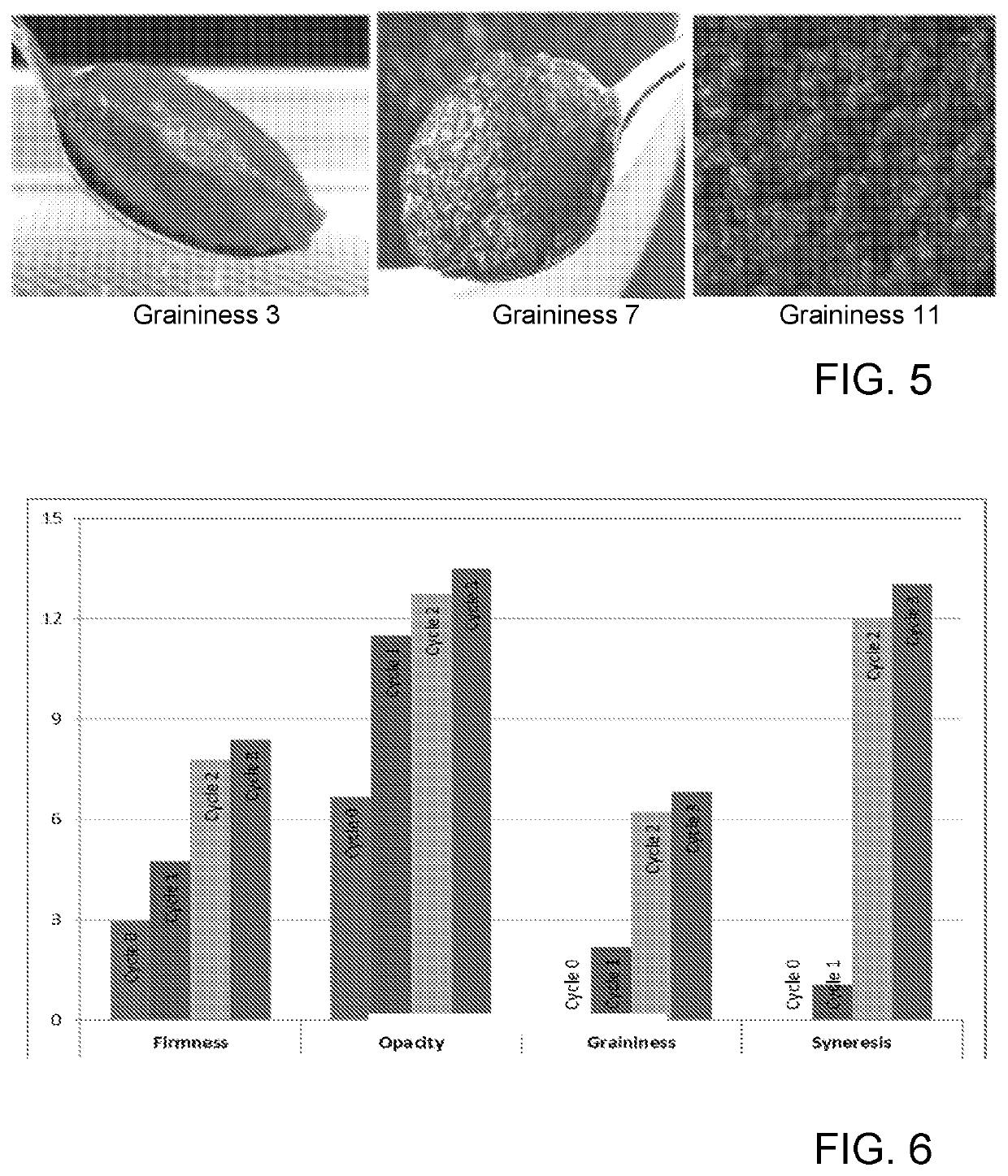

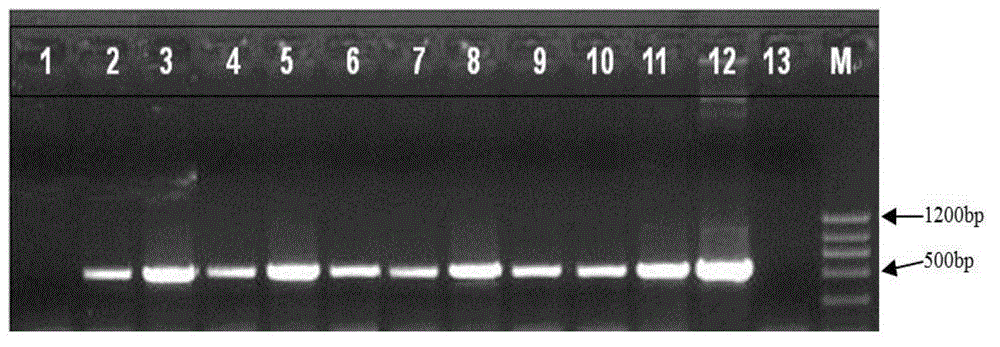

Inhibited Waxy Starches and Methods of Using Them

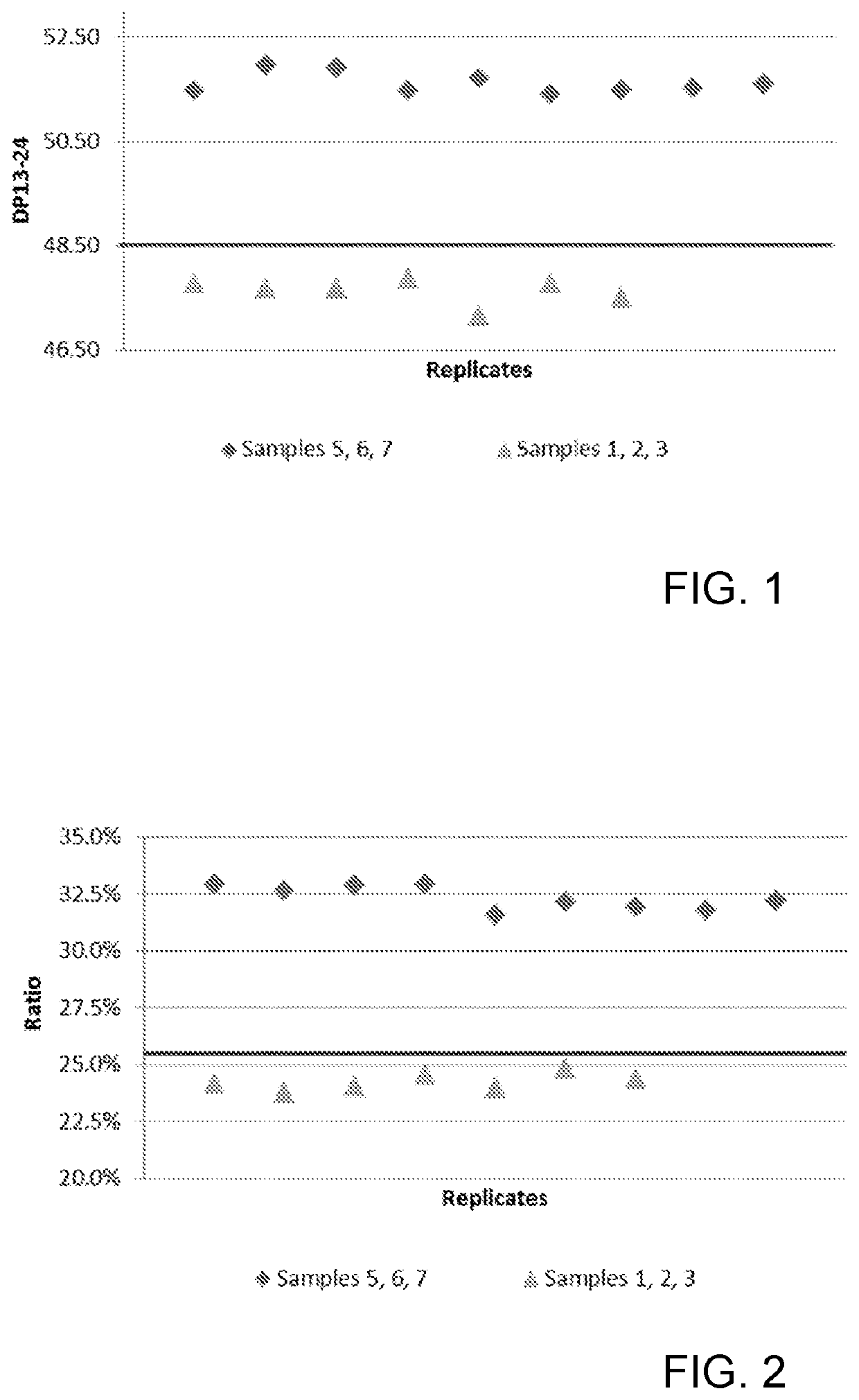

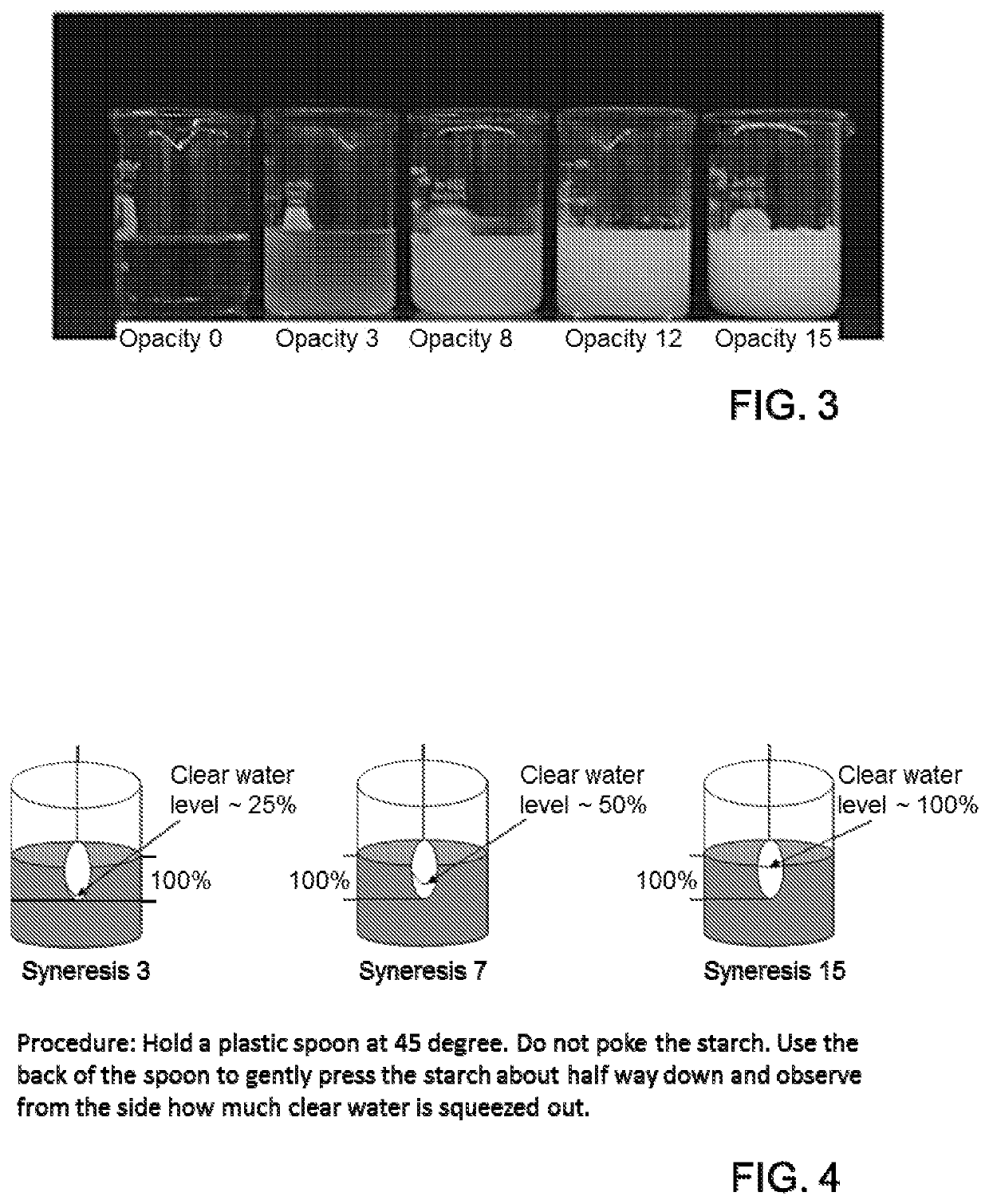

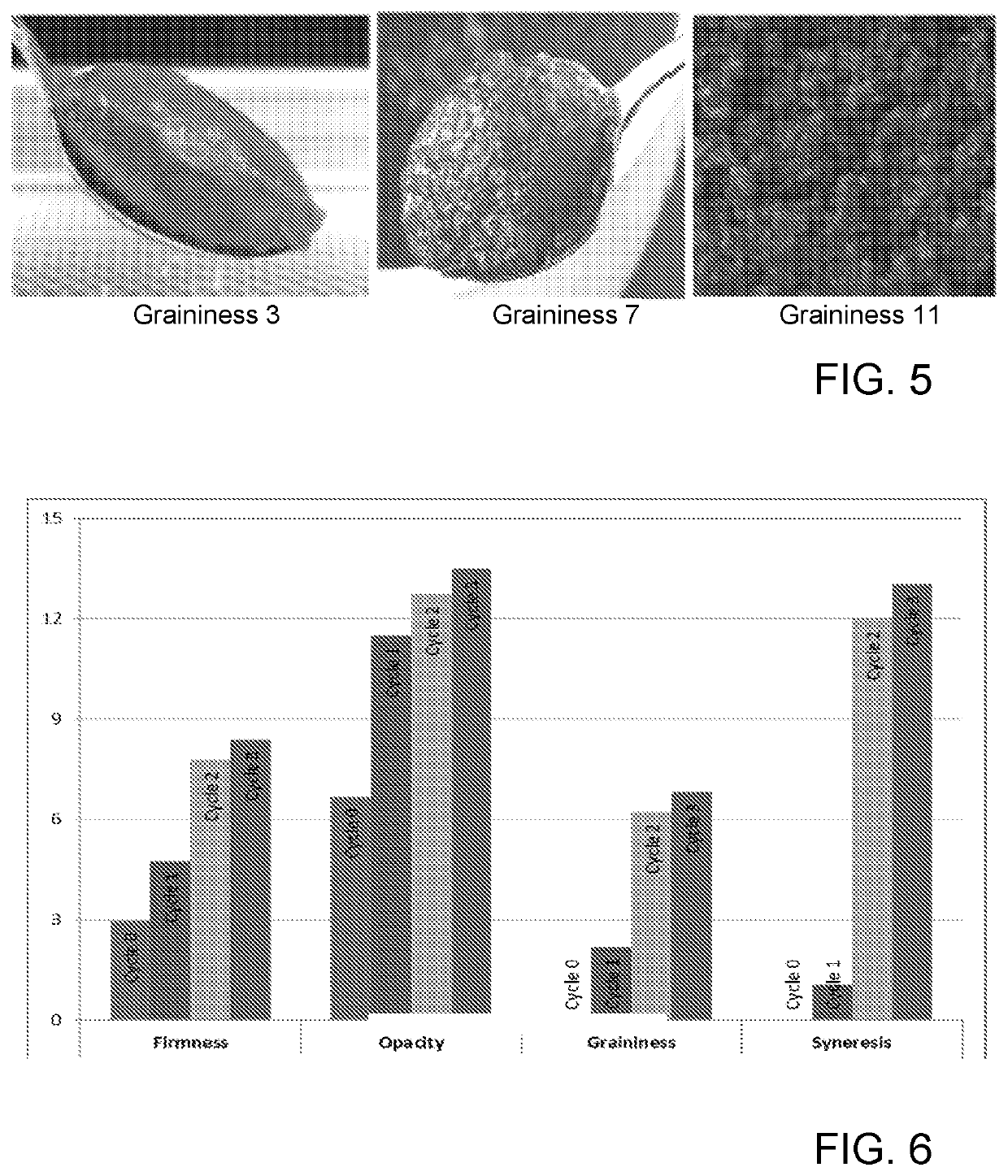

The present disclosure relates to inhibited waxy starches and methods for using them. One aspect of the disclosure is an inhibited waxy starch based on maize, wheat, or tapioca having an amylopectin content in the range of 90-100%; and a sedimentation volume in the range of 10-50 mL / g; in which the amylopectin fraction of the inhibited waxy starch based on maize, wheat, or tapioca has no more than 48.5% medium-length branches having a chain length from 13-24 (measured by a valley-to-valley method as described herein), and the starch is not pregelatinized. Methods of using the starch materials in food products are also described.

Owner:TATE & LYLE INGREDIENTS AMERICAS INC

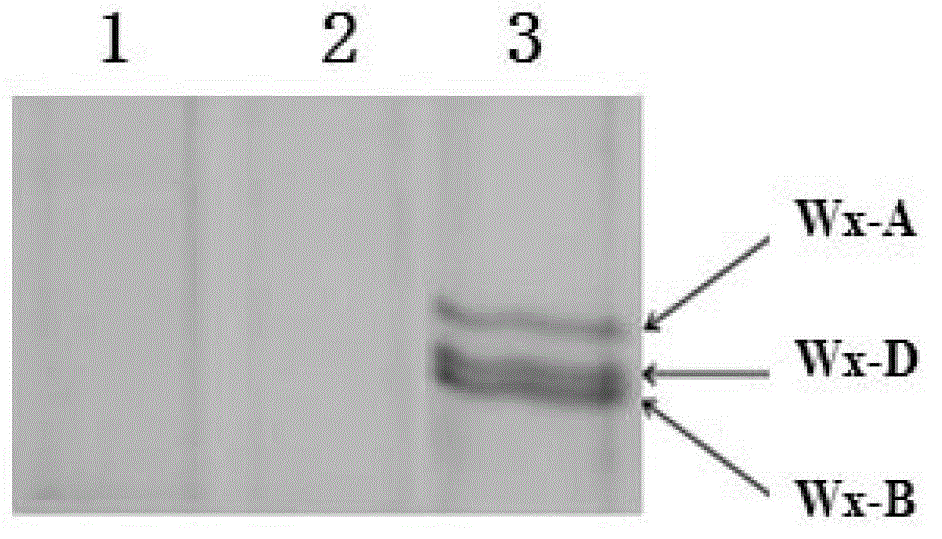

New method for formulation of full waxy starch wheat germplasm

InactiveCN102747100AComprehensive agronomic traits are goodBacteriaVector-based foreign material introductionGranule-Bound Starch SynthaseAgricultural science

The invention discloses a method for cultivation of full waxy wheat. The method for cultivation of full waxy wheat provided in the invention includes the following step of: inhibiting the expression of GBSS (granule-bound starch synthase) I gene in target wheat to obtain the full waxy wheat. The inhibition of expression of the GBSS I gene in the target wheat is realized by transferring a DNA fragment as shown in formula "SEQforward-X-SEQbackward" into the target wheat. Specifically, the SEQforward is the top 288 nucleotides in sequence 1 of a sequence table; the SEQbackward is in reverse complement with the SEQforward; the X is a spacer sequence between the SEQforward and the SEQbackward, and in sequences, the X is not complementary with and the SEQforward and the SEQbackward. Experiments prove that the wheat GBSS I gene can be silenced through a transgene silencing technology (RNAi) to obtain a GBSS I gene expression-inhibiting full waxy wheat new germplasm, and the transgenic material has excellent comprehensive agronomic characters, thus being able to be directly used for selective breeding of wheat low-amylose new strains (varieties) or be used as a patent material of breeding.

Owner:INST OF CEREAL & OIL CROPS HEBEI ACAD OF AGRI & FORESTRY SCI

Environment-friendly edible tubular product and preparation method thereof

InactiveCN110301798ASimple recipeNo side effectsCandle holdersFood shapingMaterials preparationAlcohol

The invention discloses an environment-friendly edible tubular product. The environment-friendly edible tubular product comprises 30-70 parts of main body powder, 10-30 parts of thickening powder, 2-8parts of alcohol-soluble protein, 5-20 parts of a solvent and 10-25 parts of water. The invention further provides a preparation method of the environment-friendly edible tubular product. The preparation method comprises the following steps: carrying out material preparation: adding the alcohol-soluble protein into the solvent, and adding the main body powder, the thickening powder and the waterafter full dissolution to obtain a mixture; carrying out forming: mounting a forming mold and a cutting knife of a forming machine according to the diameter and length of the product, and pouring themixture into the forming machine for extrusion forming to obtain a formed product, wherein the diameter of an inner cavity of the forming mold is 1-20 mm; carrying out air-drying: air-drying the formed product at 5-70 DEG C for 5-20 minutes; carrying out cutting: cutting the formed product according to a preset length; carrying out drying: drying the formed product at 30-120 DEG C for 10-60 minutes; and carrying out cooling, sterilizing and packaging to obtain the finished product. According to the preparation method disclosed by the invention, traditional waxy starch or plant fibers are replaced with the main body powder such as rice flour and the like, so that the product is safe and non-toxic, and the white pollution is reduced.

Owner:众智汇(厦门)生物科技有限公司

Crosslinked native and waxy starch resin compositions and processes for their manufacture

The present invention relates to an enhanced starch resin composition, methods of making the enhanced starch resin composition using environmentally benign, water-based processes, and products produced using the enhanced starch resin composition. The enhanced starch resin composition comprises a native starch and / or a waxy starch crosslinked with a multi-functional polycarboxylic acid. The starch resin composition is formed by a water-based reaction comprising using a non-toxic, water-soluble catalyst to catalyze esterification of the native starch and / or the waxy starch with the multi-functional polycarboxylic acid, thereby yielding a crosslinked starch resin composition having at least one enhanced mechanical property and / or reduced moisture absorption as compared to the native starch and / or the waxy starch.

Owner:CORNELL UNIVERSITY

Starch gel rich in fat-soluble nutritional component, preparation method for starch gel and application of starch gel.

ActiveCN111938136AImprove stabilityGood dispersionLipidic food ingredientsFood ingredient as emulsifierBiotechnologyFish oil

The invention belongs to the technical field of health product processing, and particularly relates to starch gel rich in fat-soluble component, a preparation method for the starch gel and applicationof the starch gel. The starch gel comprises the following raw materials in parts by weight: 20 parts of starch, 10-20 parts of pregelatinized waxy starch, 1-3 parts of deep-sea fish oil, 0.2-0.5 partof vitamin E, 0.2-0.5 part of octenyl succinic anhydride modified starch and 0.2-0.5 part of 1,3-butanediol. The starch gel with strong gel performance is obtained, and the pregelatinized waxy starchand the octenyl succinic anhydride modified starch can interact, so that oil drops are fixed better, and movement of the oil drops is reduced. The concentration of pregelatinized waxy starch is controlled, so that dispersion liquid has certain viscosity, starch granules added later are suspended in a mixed solution, and stirring is not needed during reheating, and thus, a firmer starch gel network structure of in-situ water absorption is formed. The process is simple, and operation is easy, thus being conducive to industrial production.

Owner:QILU UNIV OF TECH

Rice improver, cooked rice using same, and processes for preparing cooked rice

A rice improver containing a gelatinized product of an acid-treated waxy type starch or a gelatinized product of an oxidation-treated waxy type starch, wherein a cold water solubility of the rice improver in pure water at 25 degrees centigrade is equal to or higher than 50%, wherein a content of a fraction of a granular material sieved over 0.5 mm-opening (32 mesh) sieve in the rice improver is smaller than 5% by weight, and wherein a total of contents of said acid-treated waxy type starch and said oxidation-treated waxy type starch over the whole rice improver is equal to or larger than 50% by weight.

Owner:J OIL MILLS INC

Inhibited waxy starches and methods of using them

The present disclosure relates to inhibited waxy starches and methods for using them. One aspect of the disclosure is an inhibited waxy starch based on maize, wheat, or tapioca having an amylopectin content in the range of 90-100%; and a sedimentation volume in the range of 10-50 mL / g; in which the amylopectin fraction of the inhibited waxy starch based on maize, wheat, or tapioca has no more than 48.5% medium-length branches having a chain length from 13-24 (measured by a valley-to-valley method as described herein), and the starch is not pregelatinized. Methods of using the starch materials in food products are also described.

Owner:TATE & LYLE SOLUTIONS USA LLC

Barley Cultivar 'YU599-012'

ActiveUS20100162426A1Small sizeSeed and root treatmentOther foreign material introduction processesFiberBeta-glucan

A barley cultivar, designated YU599-012, is disclosed. The invention relates to the seeds of barley cultivar YU599-012, to the plants of barley YU599-012, and to methods for producing a barley plant produced by crossing barley cultivar YU599-012 with itself or another barley variety. The invention also relates to methods for producing a barley plant containing in its genetic material one or more transgenes and to the transgenic barley plants and plant parts produced by those methods. The invention also relates to barley varieties or breeding varieties and plant parts derived from barley cultivar YU599-012, to methods for producing other barley varieties, lines or plant parts derived from barley cultivar YU599-012, and to the barley plants, varieties, and their parts derived from the use of those methods. The invention further relates to hybrid barley seeds and plants produced by crossing barley cultivar YU599-012 with another barley cultivar. This invention further relates to methods for developing other barley varieties or breeding lines derived from variety YU599-012 including cell and tissue culture, haploid systems, mutagenesis, and transgenic derived lines. YU599-012 demonstrates a unique combination of traits for the human food market including waxy starch, hulless seed and increased levels of Beta-glucan fiber and Beta-glucan fiber viscosity.

Owner:HIGHLAND SPECIALTY GRAINS

Environmental friendly glue for floor

InactiveCN104312446ALong full cure timeQuality improvementNon-macromolecular adhesive additivesOrganic non-macromolecular adhesiveSodium phosphatesWaxy Starch

The invention discloses environmental friendly glue for a floor. The environmental friendly glue for the wood floor is prepared from the following raw materials in parts by weight: 0.5-1.7 parts of sodium hexametaphosphate, 5-10 parts of waxy starch, 1.8-4.2 parts of limestone, 2.3-3.8 parts of maleic anhydride, 0.8-1.5 parts of calcium hydroxide, 2.5-4.2 parts of desugared sodium lignin sulfonate, 1.5-3 parts of fish glue and 3-7 parts of soyabean protein. Compared with an existing product, the environmental friendly glue for the floor has the advantages that depositing time is long, and construction efficiency is effectively improved; complete curing time required by the environmental friendly glue for the wood floor at room temperature is short; meanwhile, raw materials of the environmental friendly glue for the floor are safe and pollution-free and can release negative oxygen ions beneficial to a human body, so that both environmental protection and air purification are realized, and quality of the air is improved.

Owner:宁贻伟

Low protein yogurts containing modified starches

The invention relates to a low protein yogurts containing modified starches. A low protein yogurt composition is provided comprising water, at least one dairy ingredient and a crosslinked waxy starch, wherein the crosslinked waxy starch is crosslinked with phosphate groups and has a peak Brabender viscosity of from about 600 to about 1500 Brabender units, and the cross-linked waxy starch is present in an amount sufficient to add viscosity to the yogurt. The crosslinked waxy starch can also be stabilized by acetylation to obtain longer shelf life.

Owner:CORN PROD DEV INC

Expansion Of Extruded Cereals With Good Source Of Fiber

Owner:THE QUAKER OATS CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com