Preparation method of straight chain dextrin embedded conjugated linoleic acid microcapsules

A technology of conjugated linoleic acid and linear dextrin, which is applied in the direction of microcapsule preparation, microsphere preparation, etc., can solve the problems of poor solubility of amylose complexes, easy auto-oxidation bioavailability of CLA, etc., and achieve small molecular weight , good solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] The application provides a method for preparing microcapsules of linear dextrin-embedded conjugated linoleic acid, the specific steps are as follows:

[0040] (1) Evenly disperse 1 g of waxy starch in 90 mL of distilled water, stir and pregelatinize in a boiling water bath, then cook at 121°C and 0.1 MPa for 20 minutes until completely gelatinized, then cool to room temperature;

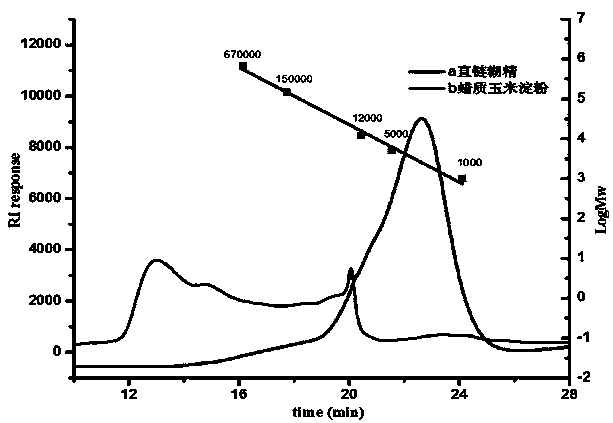

[0041](2) Add 10mL sodium acetate buffer (0.1M, PH=3.5) and 7.5 U / g starch isoamylase to the gelatinized waxy cornstarch for debranching, the reaction temperature is 40℃, and the reaction time is 12 hours; after complete debranching, boil the hydrolyzed solution in a boiling water bath for 10 min to inactivate the enzyme, centrifuge at 5000 r / min for 5 min to remove the enzyme, and freeze-dry to powder after rotary evaporation to obtain linear dextrin.

[0042] (3) Add 500mg of straight-chain dextrin powder to 5mL of 1M NaOH solution to dissolve, then add 40ml of distilled water to dilute, and...

Embodiment 2

[0052] The application provides a method for preparing microcapsules of linear dextrin-embedded conjugated linoleic acid, the specific steps are as follows:

[0053] (1) Evenly disperse 1g of waxy starch in 90ml of distilled water, stir and pregelatinize in a boiling water bath, then cook at 110°C and 0.04MPa for 30 minutes until completely gelatinized, then cool to room temperature;

[0054] (2) Add 10mL sodium acetate buffer (0.1M, PH=3.5) and 1 U / g starch isoamylase to the gelatinized waxy cornstarch for debranching, the reaction temperature is 30℃, and the reaction time is 48 hours; after complete debranching, boil the hydrolyzed solution in a boiling water bath for 10 min to inactivate the enzyme, centrifuge at 5000 r / min for 5 min to remove the enzyme, and freeze-dry to powder after rotary evaporation to obtain linear dextrin.

[0055] (3) Add 500mg of linear dextrin powder to 10mL of 1M NaOH solution to dissolve, then add 80ml of distilled water to dilute, and finally a...

Embodiment 3

[0060] The application provides a method for preparing microcapsules of linear dextrin-embedded conjugated linoleic acid, the specific steps are as follows:

[0061] (1) Evenly disperse 1g of waxy starch in 90ml of distilled water, stir and pregelatinize in a boiling water bath, then cook at 130°C and 0.17MPa for 10min until completely gelatinized, then cool to room temperature;

[0062] (2) Add 10 mL of sodium acetate buffer (0.1M, PH=3.5) and 10 U / g of starch isoamylase to the gelatinized corn starch for debranching, the reaction temperature is 60°C, and the reaction time is 12 hours; After complete debranching, the solution that completed the hydrolysis reaction was boiled in a boiling water bath for 10 minutes to inactivate the enzyme, centrifuged at 5000 r / min for 5 minutes to remove the enzyme, and then lyophilized into powder after rotary evaporation to obtain linear dextrin.

[0063] (3) Add 500mg of linear dextrin powder to 1.7mL of 1M NaOH solution to dissolve, then ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pov | aaaaa | aaaaa |

| Pov | aaaaa | aaaaa |

| Pov | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com