A method for preparing three-dimensional randomly oriented fibers

A fiber and orientation technology, which is applied in the field of preparation of micro-nano materials, can solve the problems of fiber mechanical properties and water stability degradation, and achieve the effects of small fiber diameter, ultra-high specific pore volume, and high water stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

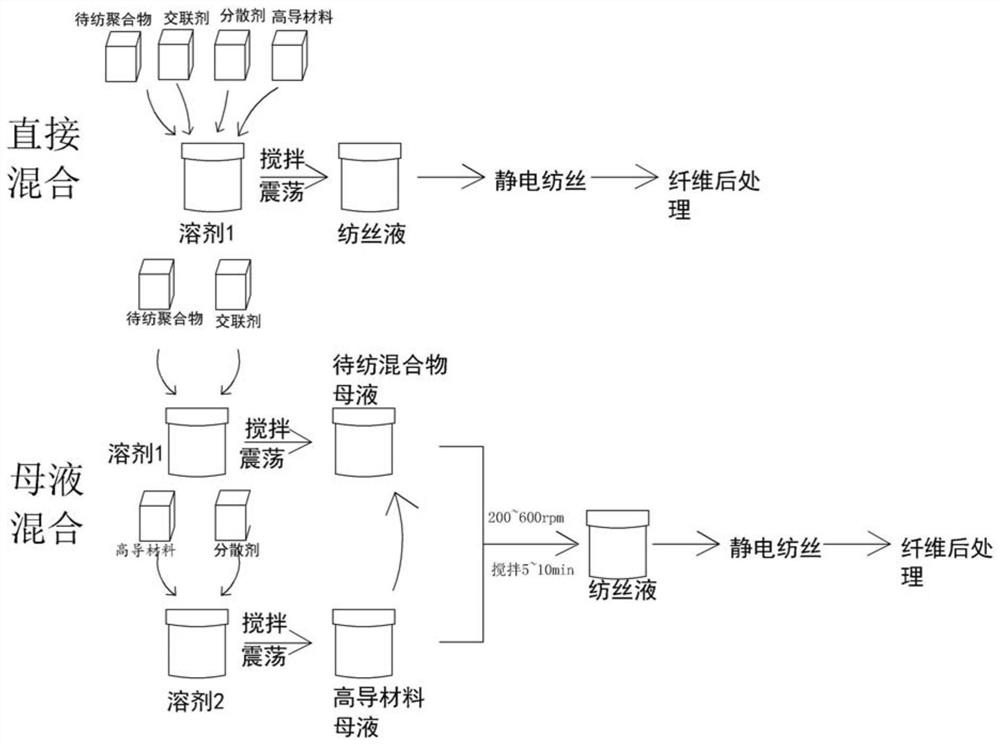

Method used

Image

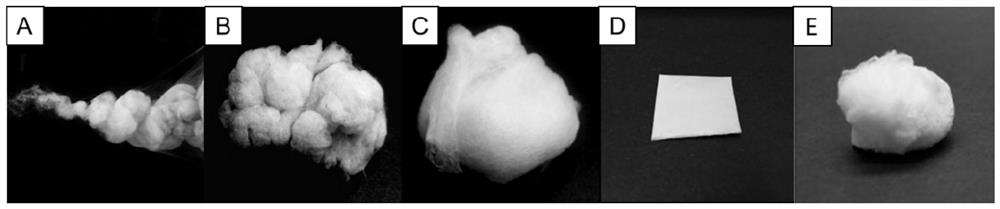

Examples

Embodiment 1

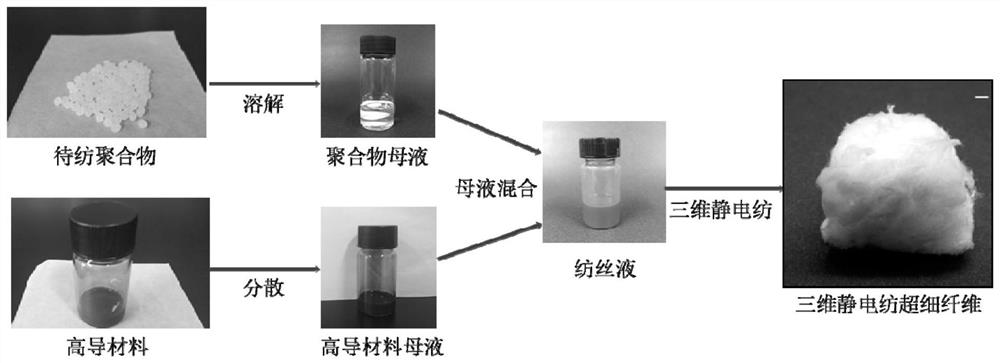

[0062] Mix chloroform and N,N-dimethylformamide at a volume ratio of 9:1 as a solvent, dissolve polylactic acid (PLA) in the mixed solvent with a concentration of 10wt.%, then stir and dissolve at room temperature at 600rpm for 24h to obtain PLA mother liquor . Glycerol is used as a solvent with a concentration of 0.1wt.%, and then 2wt.% of nano-silver particles are added and shaken until completely dispersed to obtain a mother liquid of nano-silver particles. PLA mother liquor and nano-silver particle mother liquor are mixed by 10:0.8 mass ratio, 200rpm stirs 5min, obtains spinning solution, and the ratio of nano-silver particle and PLA is 1.6wt.% in the spinning solution, and the conductivity of solution can reach 0.5μS / cm.

[0063] The spinning solution is placed in the solution chamber of the single-needle electrospinning device, the spinning environment is controlled at 25 ° C, 50% RH, the fiber receiving device is a flat receiver, 16 cm away from the spinneret, and the...

Embodiment 2

[0065] Add zein to 75% ethanol while stirring, to a concentration of 25wt.%, add citric acid and sodium hypophosphite to the zein solution, and the ratios are 15% and 15% of the zein mass respectively 7.5%, followed by stirring and dissolving at room temperature at 500 rpm for 24 hours to obtain a zein solution. Add glycerol subsequently, concentration is 0.05wt.%, 150rpm stirs 5min, finally adds 1wt.% nano-silver particle, shakes to nano-silver particle and disperses completely in solution and obtains spinning solution, and nano-silver particle in the spinning solution is 4.2 wt.% of zein.

[0066] The spinning solution was placed in the solution chamber of a multi-needle electrospinning device, the spinning environment was controlled at 25°C, 40% RH, the fiber receiving device was a drum-type receiver, and the rotating speed was 800r / min. The distance from the spinneret is 18cm, the solution injection speed is determined to be 1.0mL / h during the spinning process, and the vo...

Embodiment 3

[0068] Using N,N-dimethylformamide as a solvent, polyacrylonitrile (PAN) was dissolved in the solvent at a concentration of 16 wt.%, and then stirred and dissolved at 600 rpm at 70° C. for 24 hours to obtain a PAN solution. Lithium chloride (LiCl) was dissolved in the PAN solution at a ratio of 5 wt.% of the PAN. Then stir at 600 rpm for 10 min until the solution is completely uniform to obtain a spinning solution.

[0069] The spinning solution is placed in the solution chamber of the metal wire electrospinning device, the spinning environment is controlled at 25 ° C, 50% RH, the fiber receiving device is a non-woven PP fiber felt, and the distance from the metal wire nozzle is 12 cm. The spinning speed was 1.5mL / h, and the voltage was kept at 18kV. After the fibers are collected, LiCl is dissolved in distilled water and dried to obtain a specific pore volume of 1800 cm 3 / g, three-dimensional randomly oriented PAN ultrafine fibers with a fiber fineness of 0.5 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive modulus | aaaaa | aaaaa |

| compressive modulus | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com