Potabilization process

A process and water purification technology, applied in water/sewage treatment, chemical instruments and methods, waste water treatment in processing, etc., can solve problems such as high viscosity and achieve the effect of reducing turbidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0138] This example presents a different process including a coagulation-flocculation step not according to the invention. These examples make it possible to show the problems solved by the invention.

[0139] products used

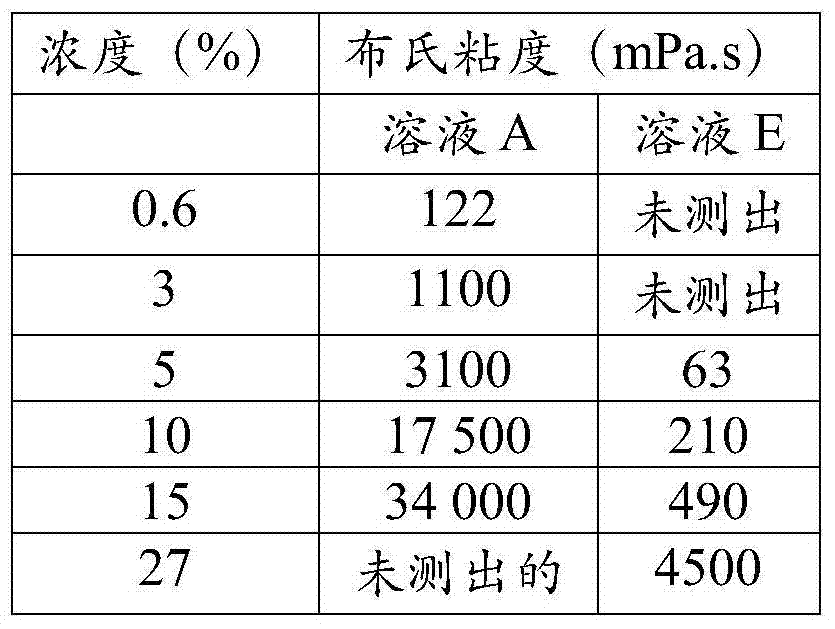

[0140] "A": Comparative cationic starch solution according to test A with a Brookfield viscosity of 17 500 mPa.s. This solution, "A", was obtained from a cationic starch (non-waxy potato base) with a DS of 0.16. This starch is soluble in water at 20°C.

[0141] "B": comparative cationic starch solution according to test A, whose Brookfield viscosity is 53 000 mPa.s. This solution, "B", was obtained from a cationic starch (waxy corn matrix) with a DS of 0.05. At 20°C, this starch is insoluble, and therefore the solution was prepared by cooking the solution at 95°C for 15 minutes.

[0142] These first two liquid starch compositions A and B had high viscosity. They cannot be in the form of compositions with high solids content that can be easily pumpe...

example 2

[0153] This example illustrates the use of the invention in combination with a starch solution, iron salt as metal salt.

[0154] "A": The same solution as in Example 1.

[0155] "D": Comparative cationic starch solution according to test A, whose Brookfield viscosity is 350 mPa.s. This solution "D" was obtained from a non-waxy cationic starch (potato base) having a DS of 0.16 which had been subjected to enzymatic hydrolysis. This starch is soluble in water at 20°C.

[0156] "E": cationic starch solution according to the invention, according to test A, whose Brookfield viscosity is 210 mPa.s. This solution "E" was obtained from a cationic starch (waxy maize substrate) which had been subjected to an enzymatic hydrolytic treatment with a DS of 0.05. This starch is soluble in water at 20°C.

[0157] "F": cationic starch solution according to the invention according to test A, the Brookfield viscosity of which is 810 mPa.s. This solution, "F", was obtained from a cationic sta...

example 3

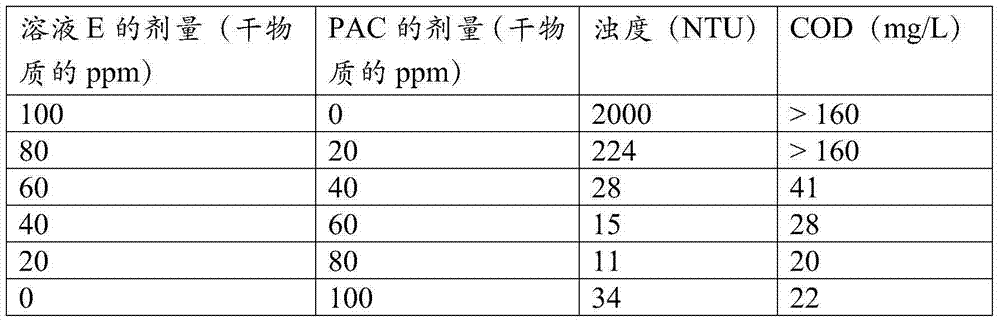

[0167] This example illustrates the invention by using an aluminum salt as a metal salt with a starch solution.

[0168] PAC: poly aluminum chloride

[0169] "G": 70 / 30 mixture of PAC and A by mass

[0170] "H": 70 / 30 mixture of PAC and E by mass

[0171] Mixtures "G" and "H" were evaluated by beaker testing for the purpose of potability of river water taken from the River Leith (initial turbidity 6 NTU). Fill the water with shoreline sludge to achieve a turbidity of 50 NTU. The scheme is the same as in the previous example. The results obtained are collected in Table 4.

[0172] Table 4

[0173] test mixture

Turbidity of supernatant (NTU)

Turbidity reduction %

G

0.4

99.1%

H

0.5

99.0%

[0174] Mixture H was as effective as Mixture G.

[0175] After 2 months of storage, Mixture H had a stable viscosity and was just as effective in the process. It should be noted that, as in the case of the starch solution useful for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com