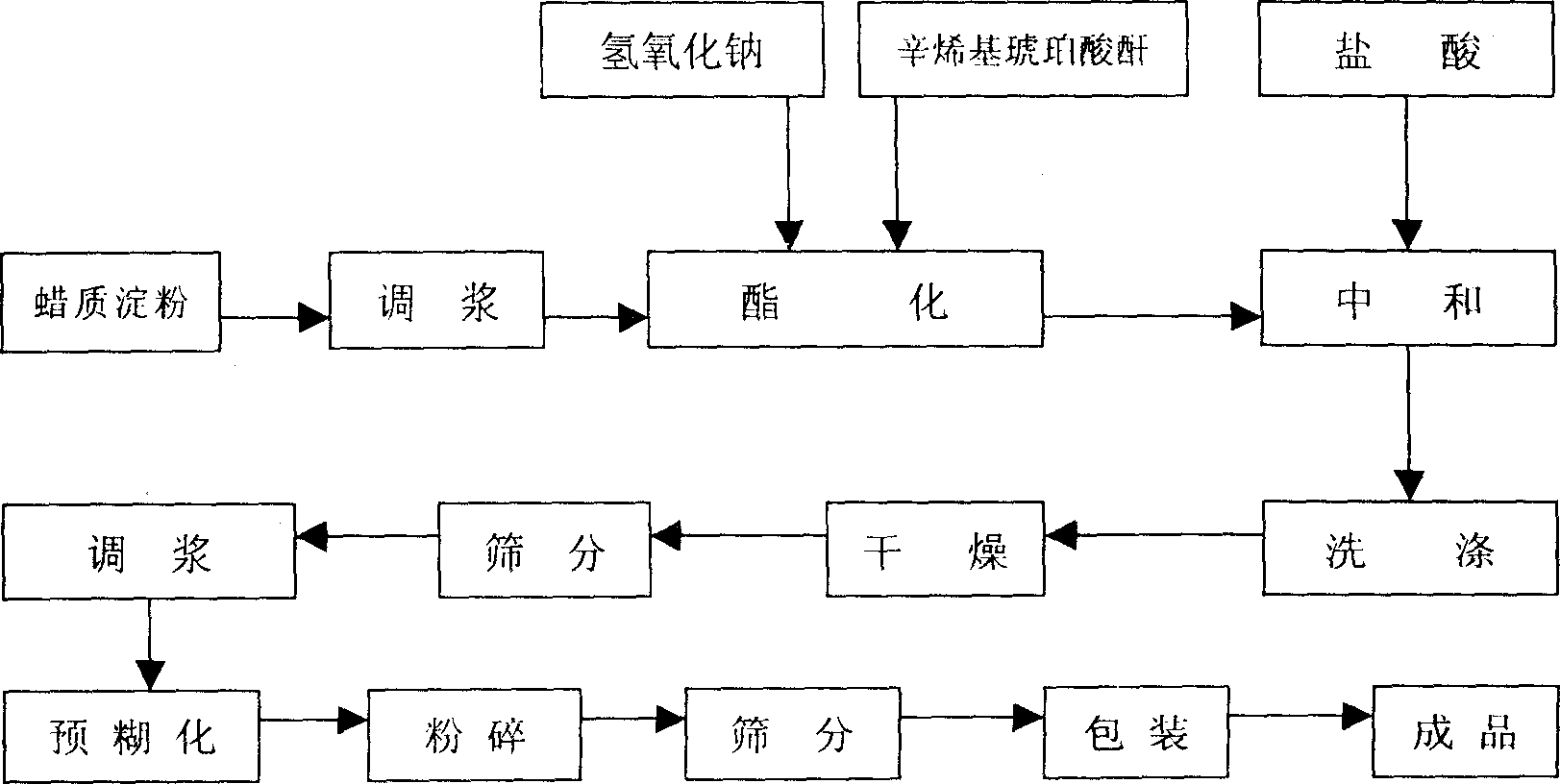

Predextrinization octeneyl succinate starch and its preparation method

A technology of octenyl succinate and pregelatinization, which is applied in the field of modified starch and its preparation, can solve problems such as limitations, and achieve the effects of low production cost, reduced production cost, and simple application process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Embodiment 1: first add 180 kilograms of water to 100 kilograms of waxy starches and adjust it into 20-23Be starch slurry in the reactor, constantly stir, and add the sodium hydroxide solution that mass concentration is 3-3.8% in the kettle to adjust the pH value to 7.5, Add 4.5 kg of octenyl succinic anhydride, keep the temperature at 30±1°C to make it react, and continuously dropwise add sodium hydroxide solution with a mass concentration of 3-3.8% during the reaction to maintain the pH value at 7.5, when the pH value no longer drops After continuing to react for 1 hour, add mass concentration and be that 8-10% hydrochloric acid solution is neutralized to pH value 6.0-7.0, add 200 kilograms of water washings, sedimentation in the kettle, then wash, sedimentation in the same way, to remove impurity (chlorination) Sodium or other chemical residues) to obtain the primary product of octenyl succinate starch, adjust the primary product into a starch milk with a mass concent...

Embodiment 2

[0026] Embodiment 2: The steps are the same as in Embodiment 1, except that the pH value of the esterification process is maintained at 8.0, and the reaction temperature is maintained at 30±1°C.

Embodiment 3

[0027] Embodiment 3: The steps are the same as in Embodiment 1, except that the pH value of the esterification process is maintained at 8.5, and the reaction temperature is maintained at 30±1°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com