Intramolecular Cr3+ cross-linked polymer gel and its preparation method

A technology of cross-linking polymers and polymers, which is applied in the direction of drilling compositions, chemical instruments and methods, etc., and can solve the problem that polymer molecules cannot achieve a wide range of "intermolecular" cross-linking reactions and polymer gel mines Poor test results, polymer gel molecular configuration damage and other problems, to achieve good technical economy, fast gelation speed, large flow resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

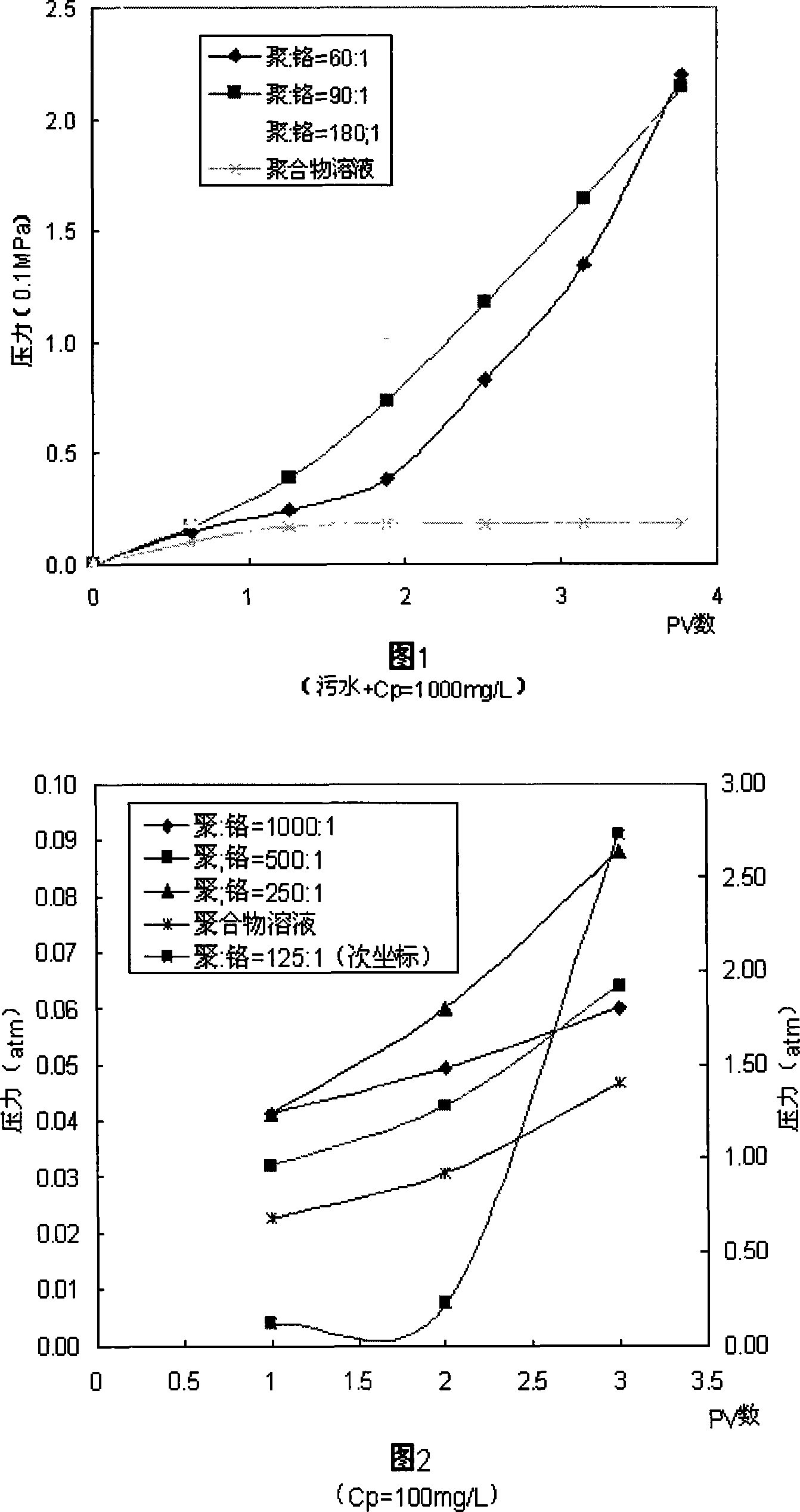

[0016] Example 1. The Bohai NB35-2 oil field is located in the central part of the Bohai Sea. The heterogeneity of the oil reservoir is relatively serious, and the water flooding development effect is relatively poor. Technical measures for profile control are required. Table 1 shows the experimental results of polymer solution and polymer gel viscosity and time. The polymers in the table are polymers produced by Fushun Longfeng Chemical Factory, with a relative molecular mass of 1700×10 4 . Solvent water is NB35-2 oilfield production sewage with a salinity of 7500mg / L. The crosslinking agent is organic chromium. The experimental temperature is 50°C.

[0017] The relationship between polymer solution and gel viscosity and time (mPa.s) Table 1

[0018]

water type

concentration

(mg / L)

poly:chrome

time (d)

1

2

5

10

20

30

1000

60∶1

3.6

4.0

3....

Embodiment 2

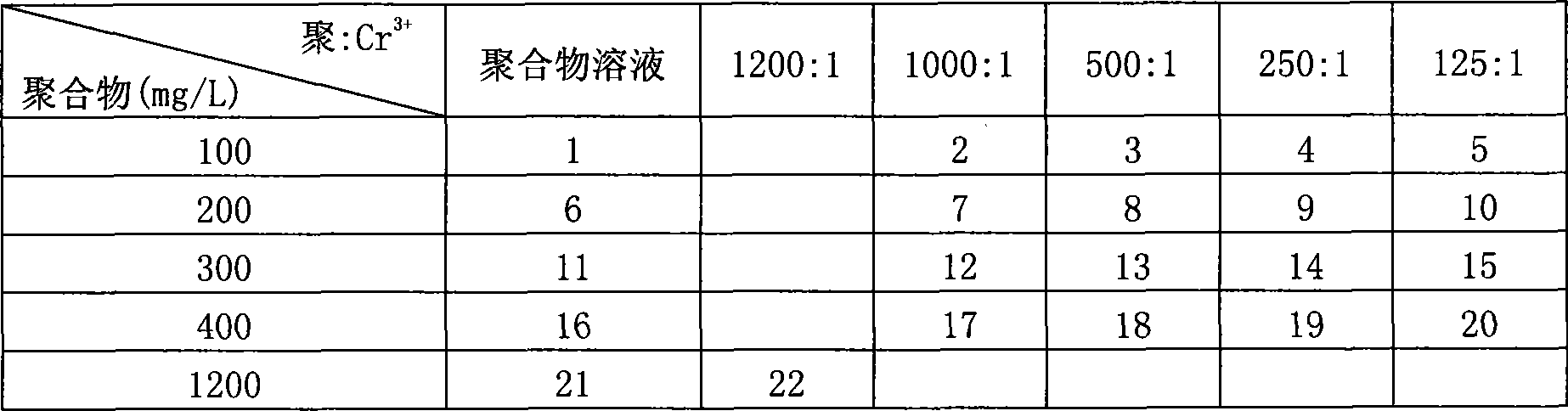

[0021] Example 2, the polymer used in the experiment is a "high-resolution" polymer produced by Daqing Refining and Chemical Company, with a relative molecular mass of 1600×10 4 , the solid content is 90%; the water is LD10-1 oil field well water; the cross-linking agent is organic chromium, and the effective content is 2.7%. Columnar core, geometric size φ25×100mm, gas permeability 1000×10 -3 μm 2 .

[0022] The polymer solution and polymer gel were prepared according to the formula listed in Table 1, placed at 62°C for 24 hours, and then the core flow experiment was carried out.

[0023] The polymer solution or polymer gel was injected into the core at a rate of 0.3 mL / min, and the experimental data of injection pressure and PV number were recorded. By comparing the injection pressure of the polymer gel with the polymer solution of the same concentration, the gelation status of the polymer gel can be evaluated.

[0024] Experimental protocol number and polymer solution a...

Embodiment 3

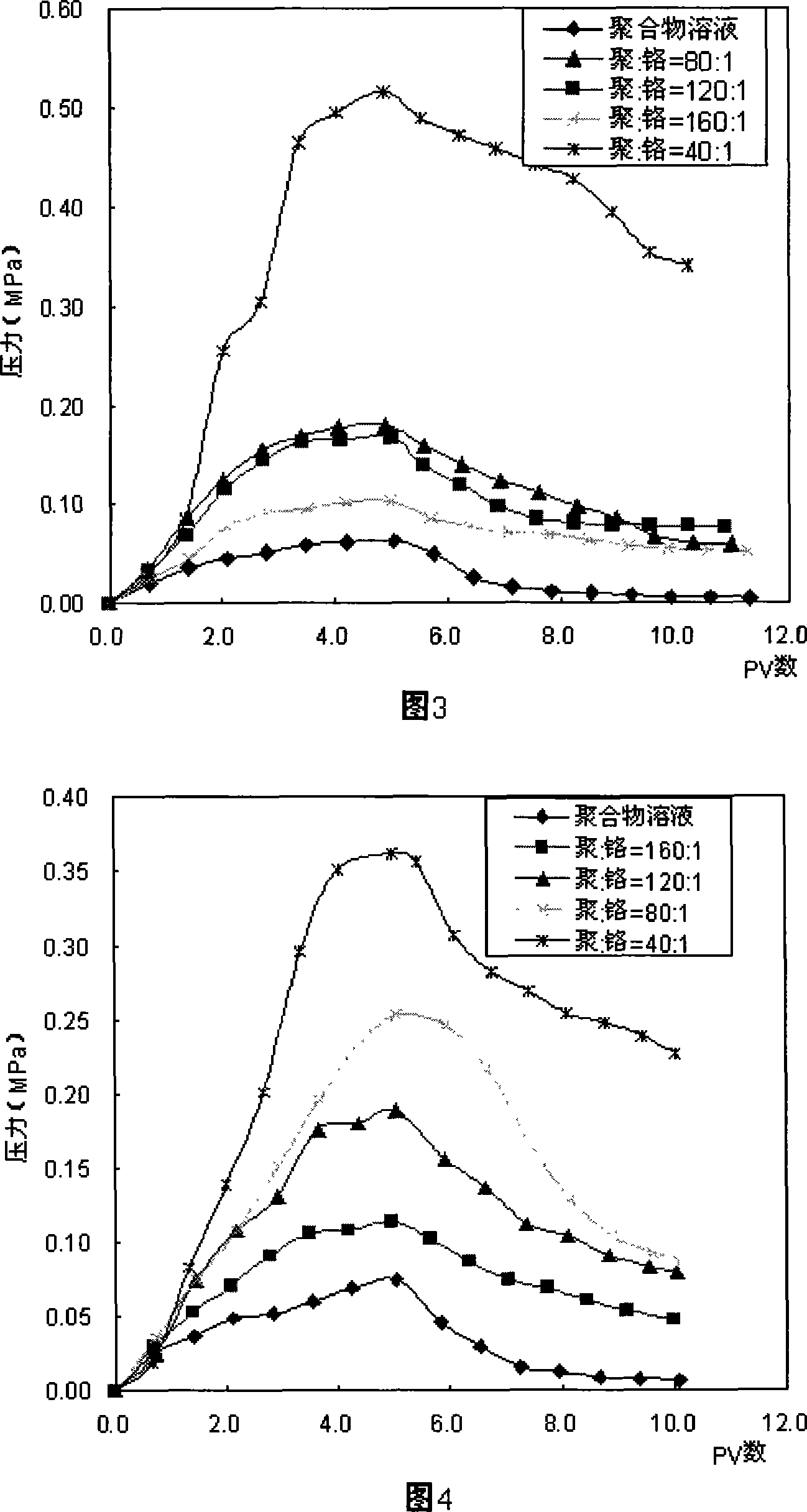

[0034] Embodiment 3, Bohai Chengbei oilfield sewage, NaHCO 3 Type, the total salinity is 4600mg / L. The polymer is the "Daqing Super High" polymer of Daqing Refining and Chemical Company, with a relative molecular mass of 2500×10 4 , solid content 90%, polymer concentration 1600mg / L. Salinity regulator NaCO 3 , a concentration of 1.2%. The concentration of auxiliary agent (thiourea) is 160mg / L. The crosslinking agent is organic chromium with an effective content of 2.7%. Columnar core, geometric size φ25×100mm, gas permeability K g ≈1000×10 -3 μm 2 .

[0035] The viscosity test data of polymer solution and polymer gel are shown in Table 4, the test results of resistance coefficient and residual resistance coefficient are shown in Table 5 and Table 6, and the relationship curve between injection pressure and PV (pore volume) number during the test is shown in Figure 3 and Figure 4 .

[0036] Polymer solution and polymer gel viscosity test results Table 4

[0037]

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Gas permeability | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com