Cosolvent for methanol gasoline and preparation method of cosolvent

A methanol gasoline and co-solvent technology, applied in the field of methanol gasoline co-solvent and preparation thereof, can solve the problems of unfavorable long-term storage of methanol gasoline, poor convenience in cold start, insufficient combustion, etc., and achieves excellent water stability and low biological Degradable, low irritating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

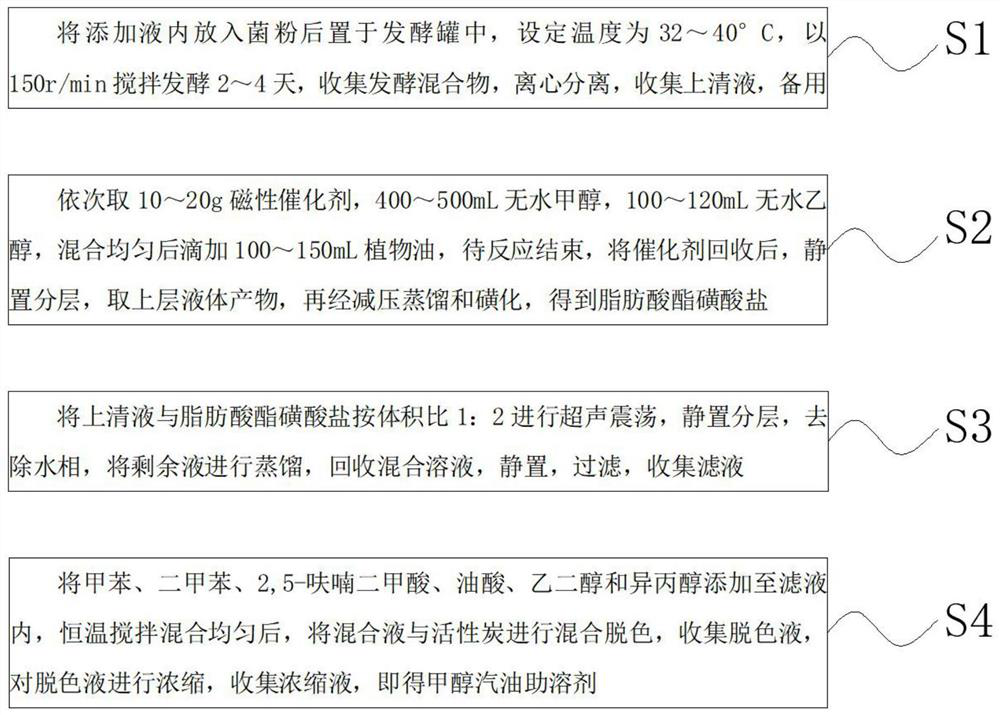

[0028] see figure 1 , the present invention provides a technical solution:

[0029] A co-solvent for methanol gasoline, prepared from the following raw materials in parts by weight: fatty acid ester sulfonate: 50 parts, toluene: 10 parts, xylene: 8 parts, 2,5-furandicarboxylic acid: 0.3 parts, oleic acid: 10 parts, ethylene glycol: 8 parts, isopropanol: 10 parts, additive solution: 50 parts and magnetic catalyst: 1 part.

[0030] see figure 1 , the additive solution is prepared by the following method:

[0031] According to the mass ratio of 1:3:4, take beeswax, peeled grapes and water and put them into a pulverizer for pulverization, collect the pulverization mixture, and take 70 parts of pulverization mixture, 40 parts of yeast extract, and 15 parts of fatty acid in parts by weight Methyl ester, 13 parts of lysine and 3 parts of sodium chloride, mix evenly, sterilize and get the additive solution;

[0032] see figure 1 , the magnetic catalyst is prepared by the followin...

Embodiment 2

[0045] see figure 1, the present invention provides a technical solution:

[0046] A co-solvent for methanol gasoline, prepared from the following raw materials in parts by weight: fatty acid ester sulfonate: 70 parts, toluene: 15 parts, xylene: 15 parts, 2,5-furandicarboxylic acid: 0.5 parts parts, oleic acid: 15 parts, ethylene glycol: 10 parts, isopropanol: 20 parts, additive solution: 60 parts and magnetic catalyst: 5 parts.

[0047] see figure 1 , the additive solution is prepared by the following method:

[0048] According to the mass ratio of 1:3:6, take beeswax, peeled grapes and water and put them into a pulverizer for pulverization, collect the pulverization mixture, and take 80 parts of pulverization mixture, 45 parts of yeast extract, and 20 parts of fatty acid in parts by weight. Methyl ester, 15 parts of lysine and 5 parts of sodium chloride, mixed evenly, sterilized to obtain the additive solution;

[0049] see figure 1 , the magnetic catalyst is prepared b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com