Radiation-proof antibacterial fabric

An antibacterial fabric and anti-radiation technology, applied in the field of textile fabrics, can solve the problems of high price, anti-radiation and antibacterial properties that need to be further improved, and achieve the effects of short process, saving preparation cost and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

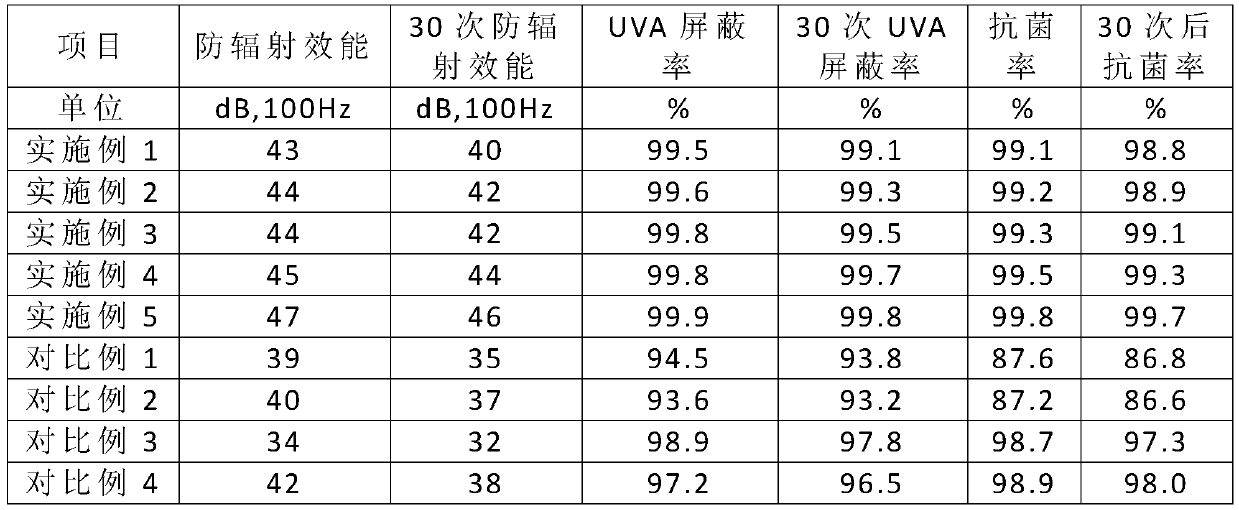

Examples

Embodiment 1

[0031] A preparation method of anti-radiation antibacterial fabric, comprising the steps of:

[0032] Step S1, 4-(2-thienyl)-3-ene-2-butanone / 5-ethylene-2-thiazolamine / limonene-1 2-epoxide / bis(triethoxysilyl)ethylene copolymerization Preparation of compounds: 4-(2-thienyl)-3-ene-2-butanone, 5-ethylene-2-thiazolamine, limonene-1 2-epoxide, bis(triethoxysilyl)ethylene , Add azobisisobutyronitrile into dimethyl sulfoxide, stir and react at 75°C for 5 hours under nitrogen atmosphere, then cool to room temperature, precipitate in water, and wash the precipitated polymer with ethanol for 3 times , and finally placed in a vacuum oven at 80°C and dried to constant weight to obtain 4-(2-thienyl)-3-ene-2-butanone / 5-ethylene-2-thiazolamine / limonene-1 2-epoxy compound / bis(triethoxysilyl)ethylene copolymer; the 4-(2-thienyl)-3-ene-2-butanone, 5-ethylene-2-thiazolamine, limonene-1 2-ring The mass ratio of oxide, bis(triethoxysilyl)ethylene, azobisisobutyronitrile and dimethyl sulfoxide is...

Embodiment 2

[0038] A preparation method of anti-radiation antibacterial fabric, comprising the steps of:

[0039] Step S1, 4-(2-thienyl)-3-ene-2-butanone / 5-ethylene-2-thiazolamine / limonene-1 2-epoxide / bis(triethoxysilyl)ethylene copolymerization Preparation of compounds: 4-(2-thienyl)-3-ene-2-butanone, 5-ethylene-2-thiazolamine, limonene-1 2-epoxide, bis(triethoxysilyl)ethylene 1. Azobisisoheptanonitrile was added to N,N-dimethylformamide, stirred and reacted at 77°C for 6 hours under a helium atmosphere, then cooled to room temperature, precipitated in water, and the precipitated polymer The substance was washed with ethanol for 4 times, and finally placed in a vacuum oven at 82°C to dry to constant weight to obtain 4-(2-thienyl)-3-ene-2-butanone / 5-ethylene-2-thiazolamine / limonene -1 2-epoxide / bis(triethoxysilyl)ethylene copolymer; the 4-(2-thienyl)-3-ene-2-butanone, 5-ethylene-2-thiazolamine, The mass ratio of limonene-1 2-epoxide, bis(triethoxysilyl)ethylene, azobisisoheptanonitrile,...

Embodiment 3

[0045] A preparation method of anti-radiation antibacterial fabric, comprising the steps of:

[0046] Step S1, 4-(2-thienyl)-3-ene-2-butanone / 5-ethylene-2-thiazolamine / limonene-1 2-epoxide / bis(triethoxysilyl)ethylene copolymerization Preparation of compounds: 4-(2-thienyl)-3-ene-2-butanone, 5-ethylene-2-thiazolamine, limonene-1 2-epoxide, bis(triethoxysilyl)ethylene 1. Azobisisobutyronitrile was added to N,N-dimethylacetamide, stirred and reacted at 80°C for 6.5 hours under a neon atmosphere, then cooled to room temperature, precipitated in water, and the precipitated polymer The material was washed 5 times with ethanol, and finally placed in a vacuum drying oven at 85°C to dry to constant weight to obtain 4-(2-thienyl)-3-ene-2-butanone / 5-ethylene-2-thiazolamine / limonene -1 2-epoxide / bis(triethoxysilyl)ethylene copolymer; the 4-(2-thienyl)-3-ene-2-butanone, 5-ethylene-2-thiazolamine, The mass ratio of limonene-1 2-epoxide, bis(triethoxysilyl)ethylene, azobisisobutyronitrile,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| antibacterial rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com