Anti-scratch foam wall covering

A technology of wall covering and foaming layer, applied in textiles and papermaking, etc., can solve the problems of easy collapse under force, poor hardness, development constraints of PVC foaming wall covering, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

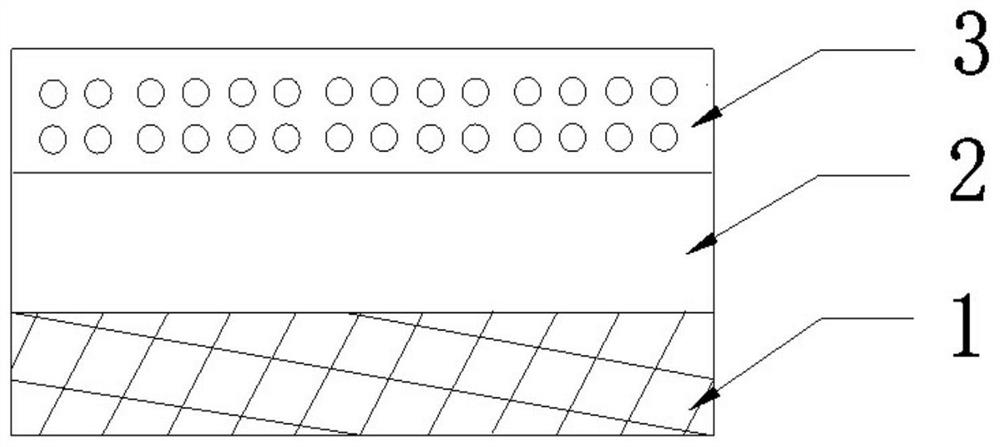

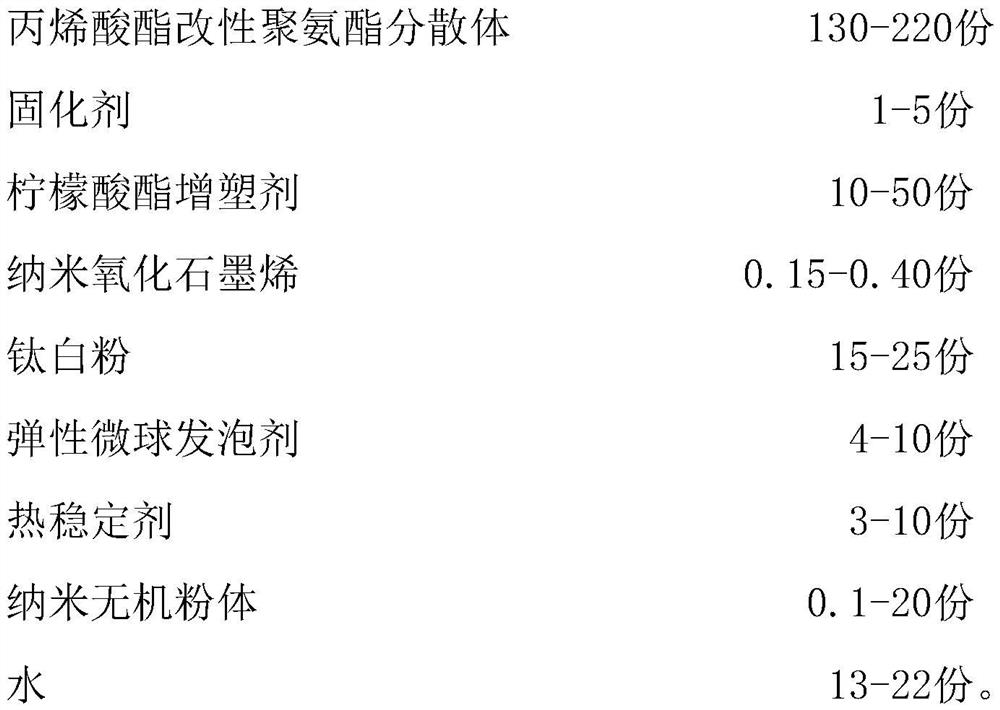

[0045] Such as figure 1 As shown, a kind of anti-scratch foam wall covering, comprises activated carbon non-woven fabric layer 1, the negative ion layer 2 that is compounded on described activated carbon non-woven fabric layer 1 and the anti-scratch foam layer that is compounded on described negative ion layer 2 3. The anti-scratch foam layer 3 is formed of anti-scratch foam slurry, and the anti-scratch foam slurry includes the following raw materials in parts by weight:

[0046]

[0047]

[0048] Wherein, the purity of the nano-graphene oxide is ≥98%, the sheet thickness of the nano-graphene oxide is 0.17 nm, and the sheet length of the nano-graphene oxide is 450 nm.

[0049] Wherein, the elastic microsphere foaming agent is a foaming agent with a core-shell structure, the outer shell is polyurethane elastomer, and the inner core is spherical polymer material particles composed of low-boiling alkanes.

[0050] Wherein, the diameter of the elastic microsphere foaming ag...

Embodiment 2

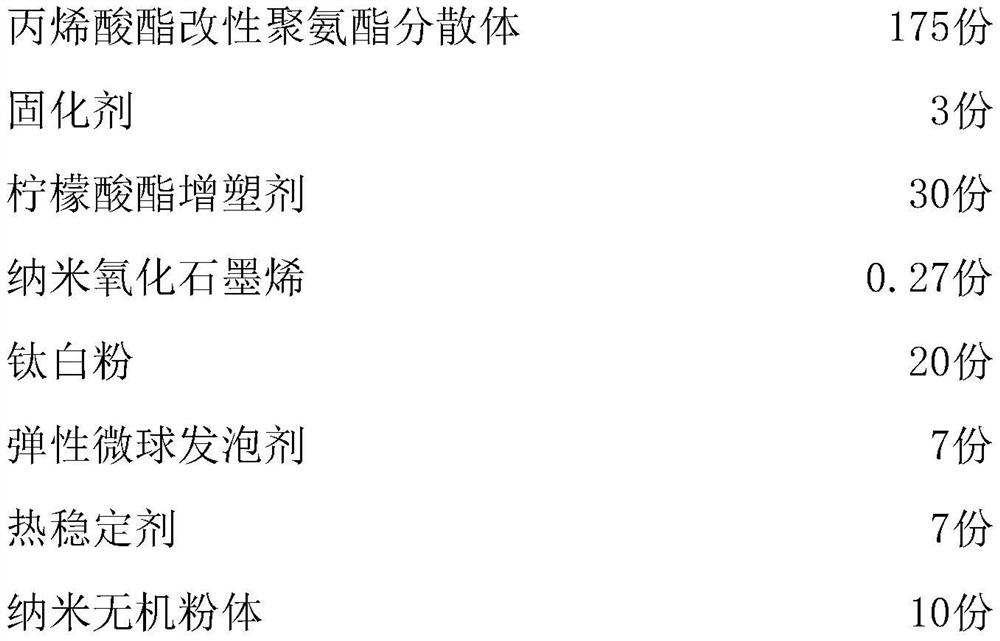

[0063] Such as figure 1 As shown, a kind of anti-scratch foam wall covering, comprises activated carbon non-woven fabric layer 1, the negative ion layer 2 that is compounded on described activated carbon non-woven fabric layer 1 and the anti-scratch foam layer that is compounded on described negative ion layer 2 3. The anti-scratch foam layer 3 is formed of anti-scratch foam slurry, and the anti-scratch foam slurry includes the following raw materials in parts by weight:

[0064]

[0065] Wherein, the purity of the nano-graphene oxide is more than or equal to 98%, the sheet thickness of the nano-graphene oxide is 0.5 nm, and the sheet length of the nano-graphene oxide is 100 nm.

[0066] Wherein, the elastic microsphere foaming agent is a foaming agent with a core-shell structure, the outer shell is polyurethane elastomer, and the inner core is spherical polymer material particles composed of low-boiling alkanes.

[0067] Wherein, the diameter of the elastic microsphere fo...

Embodiment 3

[0080] Such as figure 1 As shown, a kind of anti-scratch foam wall covering, comprises activated carbon non-woven fabric layer 1, the negative ion layer 2 that is compounded on described activated carbon non-woven fabric layer 1 and the anti-scratch foam layer that is compounded on described negative ion layer 2 3. The anti-scratch foam layer 3 is formed of anti-scratch foam slurry, and the anti-scratch foam slurry includes the following raw materials in parts by weight:

[0081]

[0082] Wherein, the purity of the nano-graphene oxide is ≥98%, the thickness of the nano-graphene oxide sheet is 2nm, and the sheet length of the nano-graphene oxide is 800nm.

[0083] Wherein, the elastic microsphere foaming agent is a foaming agent with a core-shell structure, the outer shell is polyurethane elastomer, and the inner core is spherical polymer material particles composed of low-boiling alkanes.

[0084] Wherein, the diameter of the elastic microsphere foaming agent is 30um, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com