Method for preparing nano composite fiber membrane based on electrostatic spinning technology

A nanocomposite fiber and electrospinning technology, which is applied in electrospinning, fiber processing, rayon manufacturing, etc., can solve the problems of poor usability, carcinogenicity, and easy phase separation of fiber membranes, and achieve large specific surface area and chemical The effect of stable properties and difficult phase separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] A kind of spinning solution solute mass ratio is the preparation method of polycaprolactone: polyvinylpyrrolidone=1:1 nanocomposite fiber membrane, described preparation method comprises the following steps:

[0022] ①Weigh the polycaprolactone and polyvinylpyrrolidone according to the mass ratio of 1:1, dissolve them in the trifluoroethanol solvent according to the mass fraction of 12wt%, and fully stir them evenly with a magnetic stirrer;

[0023] ② Put the composite spinning solution prepared in step ① into a syringe, select a spinning nozzle with an inner diameter of 0.33±0.01mm, set the voltage at 20kV, the flow rate of the spinning solution at 1mL / h, and the receiving distance at 18cm. The electrospinning process is carried out in the spinning machine, and finally the nanocomposite fiber membrane is directly obtained on the receiving plate;

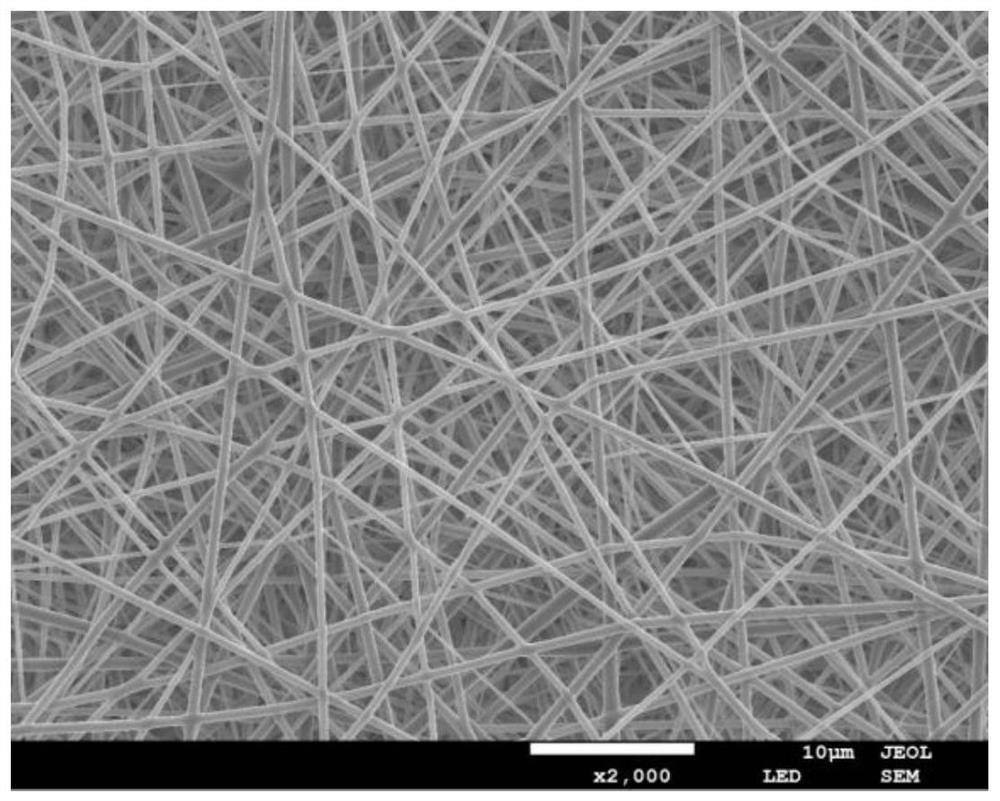

[0024] ③Remove the fiber membrane from the receiving plate with tweezers and dry it at 100°C. See the SEM picture of the ob...

Embodiment 2

[0026] A method for preparing a nanocomposite fiber film with a mass ratio of polycaprolactone: polyvinylpyrrolidone=1:1.5 in a spinning solution solute, the preparation method comprising the following steps:

[0027] ①Weigh the polycaprolactone and polyvinylpyrrolidone according to the mass ratio of 1:1.5, dissolve them in the trifluoroethanol solvent according to the mass fraction of 12wt%, and fully stir them evenly with a magnetic stirrer;

[0028] ② Put the composite spinning solution prepared in step ① into a syringe, select a spinning nozzle with an inner diameter of 0.33±0.01mm, set the voltage at 20kV, the flow rate of the spinning solution at 1mL / h, and the receiving distance at 18cm. The electrospinning process is carried out in the spinning machine, and finally the nanocomposite fiber membrane is directly obtained on the receiving plate;

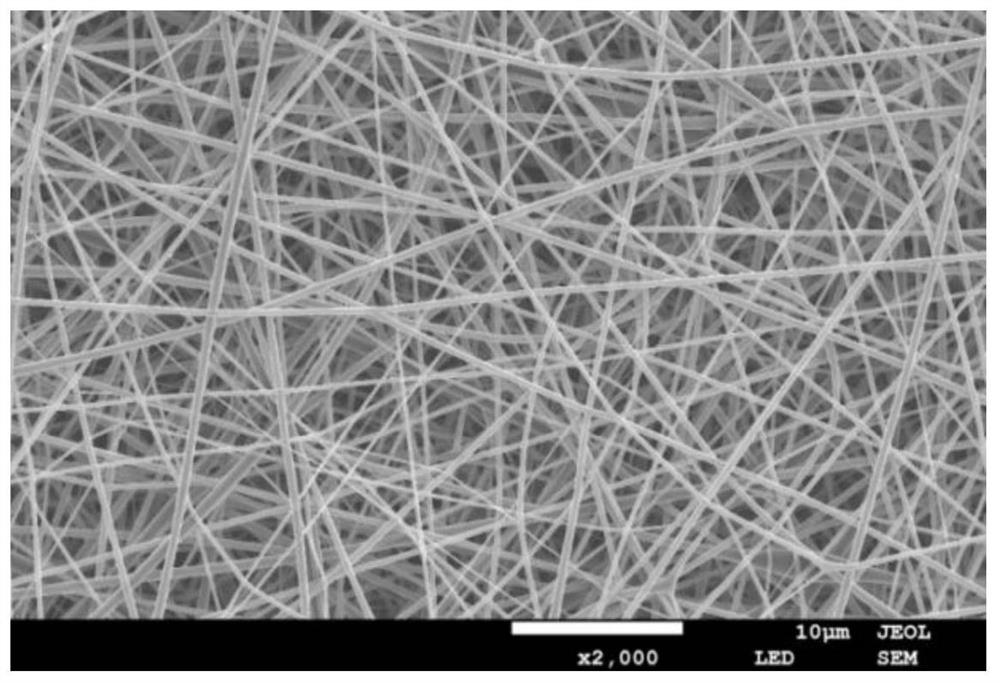

[0029] ③Remove the fiber membrane from the receiving plate with tweezers and dry it at 100°C. See the SEM picture of the obtain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com