Method for preparing paraffin/AKD composite neutral paper-making glue blending agent

A neutral sizing agent and composite technology, applied in the field of papermaking, can solve the problems of slow response, no reports of compound use of paraffin wax and AKD, etc., achieve small impact, improve the sizing degree of paper off the machine, and improve The effect of economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

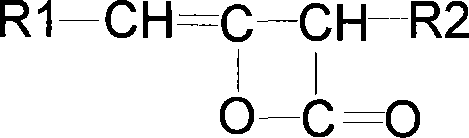

Method used

Image

Examples

Embodiment 1

[0032] A kind of preparation of paraffin / AKD composite neutral sizing agent:

[0033] (1). Mix and melt 10g of AKD and 2.5g of paraffin in a 70°C water bath, and preheat the emulsifier acrylamide and water respectively, and the preheating temperature is 65°C.

[0034] (2). Add 9 ml of emulsifier acrylamide into the melted AKD and stir for 1 minute at 10000 r / min with a fast shear mixer.

[0035] (3). Increase the speed of the fast shear mixer to 22000r / min and add 20ml of preheated water to emulsify the emulsion near the conversion point from W / O to O / W; after 2 minutes of rapid stirring, add 60ml of preheated water to continue stirring 2 minutes.

[0036] (4). Add 10 ml of an aqueous solution containing 0.5 g of PAC, and continue stirring for 1 minute.

[0037] (5). Stop stirring and quickly cool down with cold water to obtain the finished compound sizing agent emulsion. The particle size of this emulsion is 1268nm, and the Zeta potential is 38mV.

Embodiment 2

[0039] According to the above-mentioned same procedure, carry out embodiment 1 repeatedly, change paraffin consumption into 5g, make composite sizing agent emulsion. The particle size of this emulsion is 1250nm, and the Zeta potential is 37mV.

Embodiment 3

[0041] According to the above-mentioned same procedure, carry out embodiment 1 repeatedly, change paraffin consumption into 10g, make composite sizing agent emulsion. The particle size of this emulsion is 1283nm, and the Zeta potential is 34mV.

[0042] The advanced nature of the present invention is further illustrated below by two application examples:

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com