Method for preparing carboxy-type amphoteric starch in one step by semi-dry process

A technology of amphoteric starch and semi-dry method, which is applied in the field of additives in the papermaking industry. It can solve the problems of sewage discharge reaction efficiency and uneven reaction, and achieve the effects of reducing white water treatment load, improving physical strength and high conversion rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

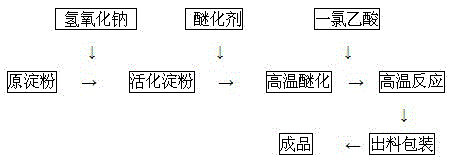

Method used

Image

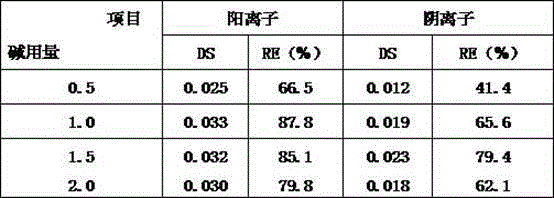

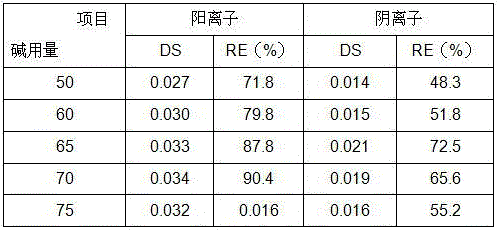

Examples

Embodiment 1

[0042] main ingreadient

[0043] (1) Corn starch:

[0044] Appearance: white powder; Moisture: ≤14.0%; Fineness (100 mesh screening rate): ≧99.5%; Spots: ≤2.0 / ㎝ 2 ;PH value (10% aqueous solution): 6-7; Ash content (dry basis): ≤0.20%; Protein (dry basis): ≤0.50%; Whiteness: ≧85.0%;

[0045] (2) Sodium hydroxide (industrial pure);

[0046] (3) Etherifying agent: 3-chloro-2-hydroxypropyl-trimethylammonium chloride (purity 69%);

[0047] (4) Monochloroacetic acid (purity 98%).

PUM

| Property | Measurement | Unit |

|---|---|---|

| whiteness | aaaaa | aaaaa |

| Ash content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com