Corn starch surface sizing agent and preparation method thereof

A technology of surface sizing agent and corn starch, which is applied in the direction of water repellent addition, coating, paper coating, etc., can solve the problems of high pollution of catalysts, waste of resources, difficulty in recycling, etc., and achieve easy promotion, low cost, and water resistance Good effect of sex and water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

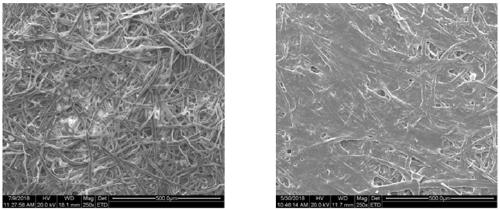

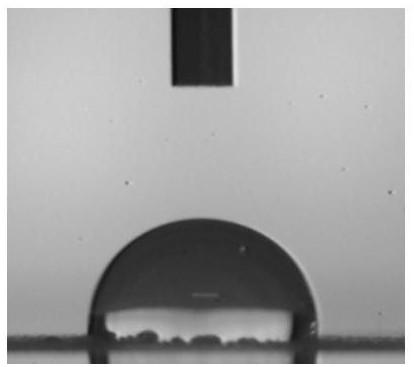

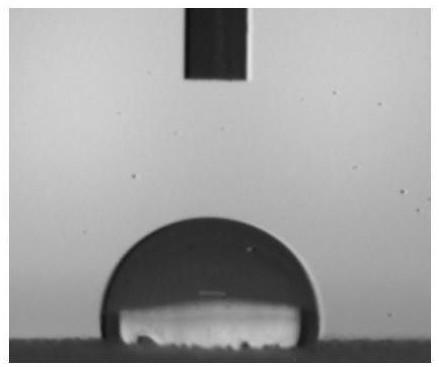

Image

Examples

preparation example Construction

[0024] As introduced in the background technology, there is a need for a surface sizing agent with simple ingredients, environmental protection, low cost, degradability and excellent performance. For this, in the first typical embodiment of the present disclosure, a corn The preparation method of starch surface sizing agent, the method may further comprise the steps:

[0025] Using cornstarch as raw material, sodium hypochlorite (NaClO) as an oxidant, and nanocrystalline cellulose as an auxiliary oxidant to prepare oxidized cornstarch; wherein, the amount of available chlorine of the NaClO relative to the dry cornstarch is 8.0-9.0wt%, and the nanocrystalline cellulose The consumption of cellulose is 0.5~0.8wt% of dry cornstarch;

[0026] The prepared oxidized corn starch is compounded with polyvinyl alcohol and glycerin to prepare a corn starch surface sizing agent.

[0027] The starches of different plants are quite different, including the shape and size of starch granules ...

Embodiment 1

[0052] A preparation method of nanocellulose / oxidized cornstarch surface sizing agent, comprising the following steps:

[0053] 1) Preparation of oxidized cornstarch:

[0054] At room temperature, dissolve cornstarch in water (the mass ratio of starch to water is 1:2), add 0.5wt% (relative to the mass of dry cornstarch) nanocrystalline cellulose into the starch solution, and heat in a water bath at 50°C And keep stirring for 0.5h to make it mix evenly, adjust the pH of the reaction system with 0.1mol / L NaOH to be 9, and add the sodium hypochlorite with an amount of available chlorine of 8.0wt% to react for 4h, adjust the pH of the reaction system to neutrality, terminate the reaction and use Wash and centrifuge repeatedly with absolute ethanol and deionized water, dry and grind to obtain oxidized corn starch, and the molecular weight of the obtained oxidized corn starch is determined to be 1.3×10 6 -5.5×10 6 , The carboxyl content is about 1.1%.

[0055] 2) Preparation and ...

Embodiment 2

[0058] A preparation method of nanocellulose / oxidized cornstarch surface sizing agent, comprising the following steps:

[0059] 1) Preparation of oxidized cornstarch:

[0060] At room temperature, dissolve cornstarch in water (the mass ratio of starch to water is 1:2), add 0.5wt% (relative to the mass of dry cornstarch) nanocrystalline cellulose into the starch solution, and heat in a water bath at 50°C And keep stirring for 0.5h to make it mix evenly, adjust the pH of the reaction system with 0.1mol / L NaOH to be 9, and add the sodium hypochlorite with an amount of available chlorine of 8.0wt% to react for 4h, adjust the pH of the reaction system to neutrality, terminate the reaction and use Wash and centrifuge repeatedly with absolute ethanol and deionized water, dry and grind to obtain oxidized corn starch, and the molecular weight of the obtained oxidized corn starch is determined to be 1.3×10 6 -5.5×10 6 , The carboxyl content is about 1.1%.

[0061] 2) Preparation and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com