Radiation-modified cellulose emulsifier and AKD emulsion prepared utilizing the emulsifier

A cellulose and emulsifier technology, applied in the direction of non-fiber pulp addition, fiber raw material treatment, water repellent addition, etc., can solve the problems of emulsion stability, sizing effect, easy mildew, low retention rate, etc. Achieve the effect of wide application value, high sizing degree and fast curing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Present embodiment technical scheme is as follows:

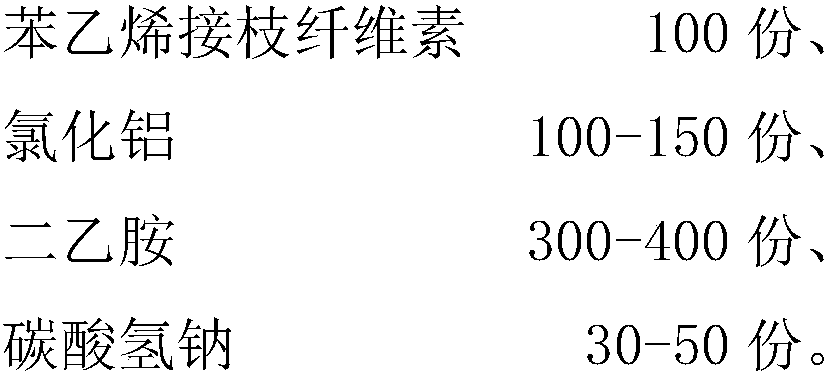

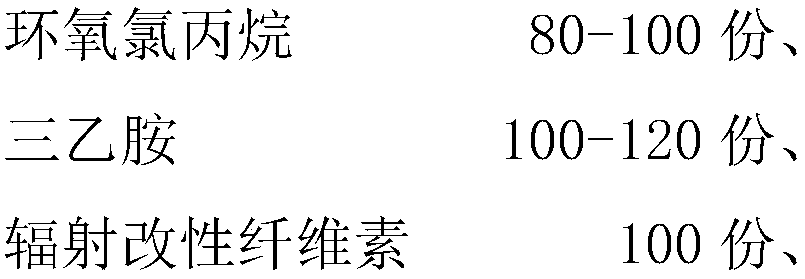

[0036] 1. First, soak the cellulose in a mixture of styrene and methanol with a styrene concentration of 3 mol / L for 24 hours to fully swell the cellulose, and then repeatedly remove oxygen in a nitrogen environment. use 60 Coγpre-irradiation induced styrene grafting to cellulose with a surface absorption dose of 20Gy. Unreacted monomers were washed away with toluene and dried at 50°C for 24 hours. Then, 100 parts of the above product and 120 g of aluminum chloride were dispersed in an appropriate amount of dichloromethane, and reacted under stirring conditions for 7 hours, and then the product was washed with tetrahydrofuran and deionized water, and dried at 50 ° C for 24 Hour. Add the above product into an appropriate amount of tetrahydrofuran, add 300 parts of diethylamine, and 30 parts of sodium bicarbonate, react at 70°C for 2 hours, then wash the product with distilled water, and dry at 50°C for 24 hours. Fin...

Embodiment 2

[0041] Present embodiment technical scheme is as follows:

[0042] 1. First, soak the cellulose in a mixture of styrene and methanol with a styrene concentration of 5 mol / L for 24 hours to fully swell the cellulose, and then repeatedly remove oxygen in a nitrogen environment. use 60 Coγ pre-irradiation induced styrene grafting to cellulose with a surface absorption dose of 50Gy, washed unreacted monomers with toluene, and dried at 50°C for 24 hours. Then, 100 parts of the above product and 1150 g of aluminum chloride were dispersed in an appropriate amount of dichloromethane, and reacted under stirring conditions for 7 hours, and then the product was washed with tetrahydrofuran and deionized water, and dried at 50 ° C for 24 Hour. Add the above product into an appropriate amount of tetrahydrofuran, add 400 parts of diethylamine, and 30 parts of sodium bicarbonate, react at 70°C for 2 hours, then wash the product with distilled water, and dry at 50°C for 24 hours. Finally, t...

Embodiment 3

[0047] Present embodiment technical scheme is as follows:

[0048] 1. First, soak the cellulose in a mixture of styrene and methanol, the concentration of styrene is 3mol / L, soak for 24 hours to make the cellulose fully swell, and then remove the oxygen repeatedly in a nitrogen environment. use 60Coγpre-irradiation induced styrene grafting to cellulose with a surface absorption dose of 40Gy, washed unreacted monomers with toluene, and dried at 50°C for 24 hours. Then, 100 parts of the above product and 130 g of aluminum chloride were dispersed in an appropriate amount of dichloromethane, and reacted under stirring conditions for 7 hours, and then the product was washed with tetrahydrofuran and deionized water, and dried at 50 ° C for 24 Hour. Add the above product into an appropriate amount of tetrahydrofuran, add 350 parts of diethylamine, and 50 parts of sodium bicarbonate, react at 70°C for 2 hours, then wash the product with distilled water, and dry at 50°C for 24 hours....

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com