Stone paper and preparation method therefor

A technology of stone paper and sepiolite velvet, applied in the field of papermaking, can solve problems such as waste, white pollution of oil resources, environmental hazards, etc., and achieve the effects of saving wood, simple process flow, and reducing papermaking costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

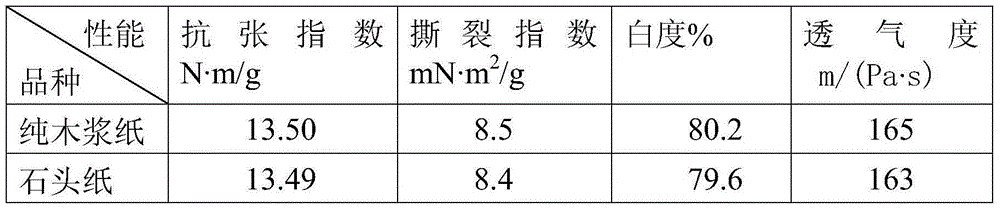

Embodiment 1

[0028] Step 1, glue making: prepare 4Kg cationic starch solution with a concentration of 5% and polyvinyl alcohol solution with a concentration of 5% respectively, specifically: weigh 200g of cationic starch or polyvinyl alcohol, add it to 3800g of water, and stir at 400r / min for 10 minutes Afterwards, be heated to boiling, continue to stir for 3 hours;

[0029] Step 2, pulping (setting degree of beating is 13.5 ° SR, quantification is 64.0g / m 2 ): take 100g coniferous wood pulp board and 80kg water and put it into a beater for beating, then add 900g of sepiolite velvet with a particle diameter of 80 objects, mechanically stir evenly, and the stirring speed is 800r / min; The paper stock is screened and purified. After purification, add 4Kg cationic starch solution obtained in step 1 and 4Kg polyvinyl alcohol solution, 500g melamine formaldehyde resin, and 200g particle diameter as nano-titanium borate of 60nm, and stir at 500r / min to obtain paper pulp slurry;

[0030] Step 3,...

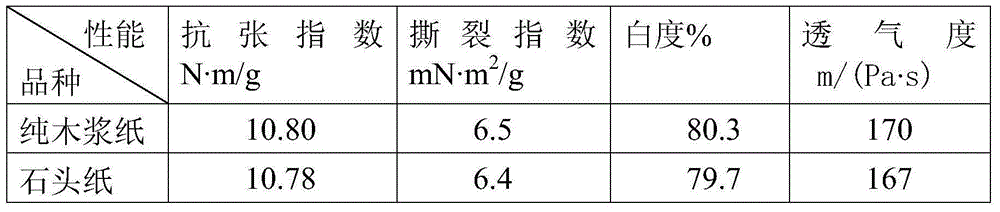

Embodiment 2

[0035] Step 1, glue making: Prepare 3Kg of 5% phosphate starch solution and 5% polyvinyl alcohol solution respectively, specifically: weigh 150g of phosphate starch or polyvinyl alcohol, add it to 2850g of water, and stir at 400r / min After 10 minutes, heat to boiling and continue to stir for 3 hours; prepare 16Kg of 1% cationic polyacrylamide solution, specifically: weigh 160g of cationic polyacrylamide, add it to 15.84Kg of water, stir at 400r / min for 10 minutes, Heat to boiling and continue to stir for 3 hours;

[0036] Step 2, pulping (setting degree of beating is 13.5 ° SR, quantification is 50.0g / m 2 ): take 200g coniferous wood pulp board and 90kg water and put it into a beater for beating, then add particle diameter and be 90 mesh sepiolite wool 800g, mechanically stir evenly, stirring speed is 900r / min; The paper material is screened and purified. After purification, add 3Kg phosphate ester starch solution obtained in step 1 and 3Kg polyvinyl alcohol solution, 400g ur...

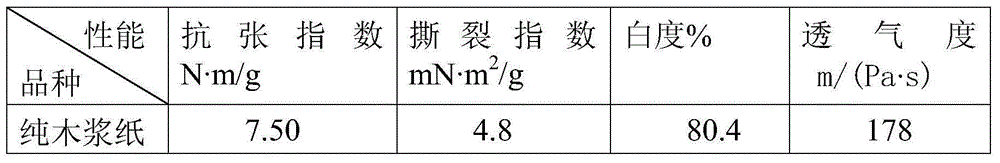

Embodiment 3

[0042] Step 1, glue making: prepare respectively 2Kg concentration 3% sodium carboxymethyl cellulose solution and concentration 5% polyacrylamide solution with a molecular weight of 1 million, specifically: weigh 60 g of sodium carboxymethyl cellulose and add it to 1940 g of water , stir at 400r / min for 3 hours until the sodium carboxymethylcellulose is completely dissolved; weigh 100g of polyacrylamide with a molecular weight of 1 million, add it to 1900g of water, stir at 400r / min for 10 minutes, heat to boiling, and continue stirring for 2 hours ;

[0043] Step 2, pulping (setting beating degree is 13.5 ° SR, quantitative is 36.0g / m 2 ): take by weighing 300g softwood pulp board and 100kg water and put it into a beater for beating, then add 700g of sepiolite wool with a particle diameter of 100 mesh, mechanically stir evenly, and the stirring speed is 1000r / min; The paper material is screened and purified, and after purification, add respectively 2Kg sodium carboxymethylce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com