Deinking process for waste paper

A waste paper deinking and waste paper technology, which is applied in pulp bleaching, textile and paper making, pulp fat/resin/pitch/wax removal, etc., can solve the problems of low ash content and yield, high production cost, high investment, etc. Achieve the effect of increasing ash content and fiber yield, reducing production cost and reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

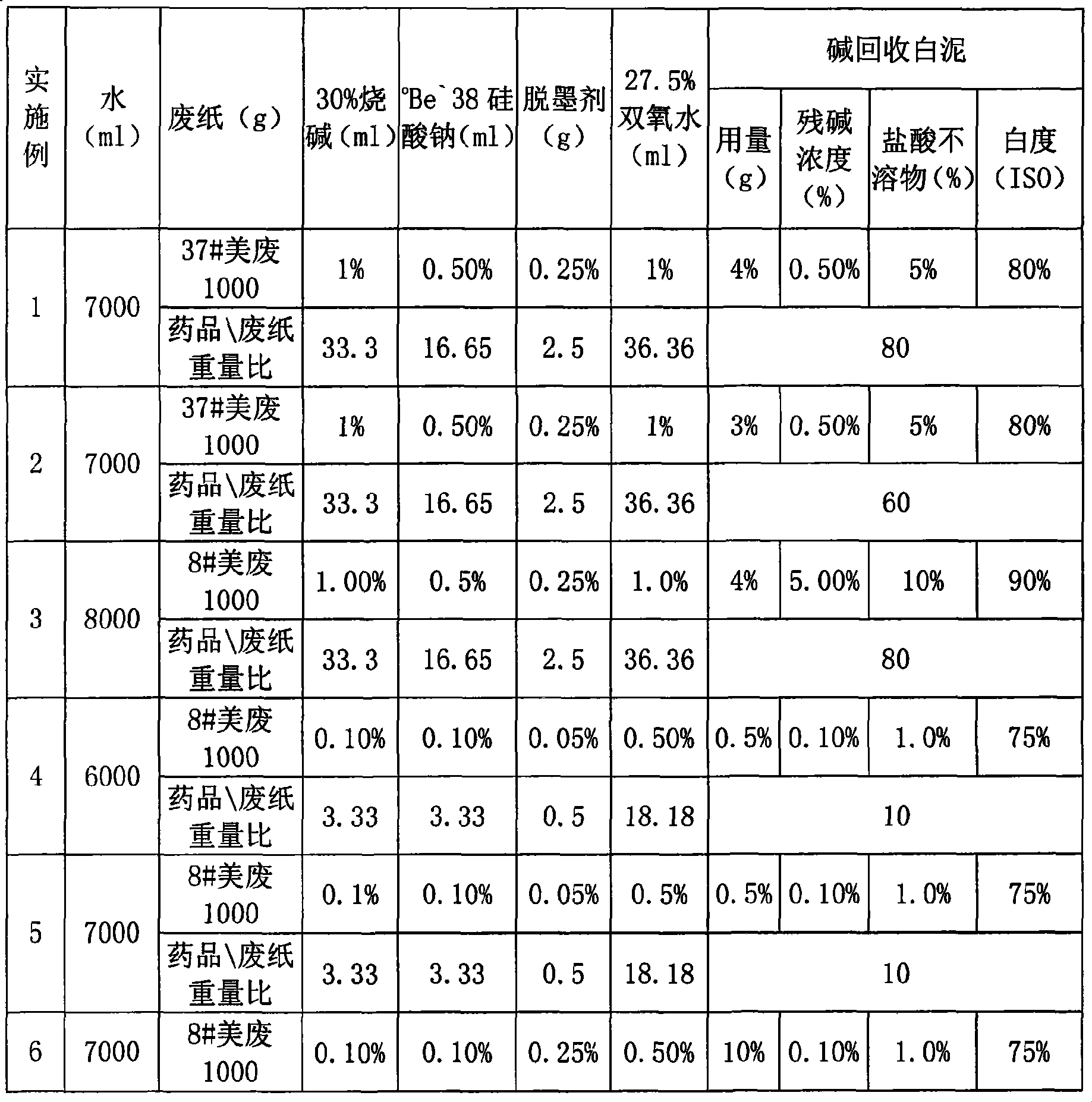

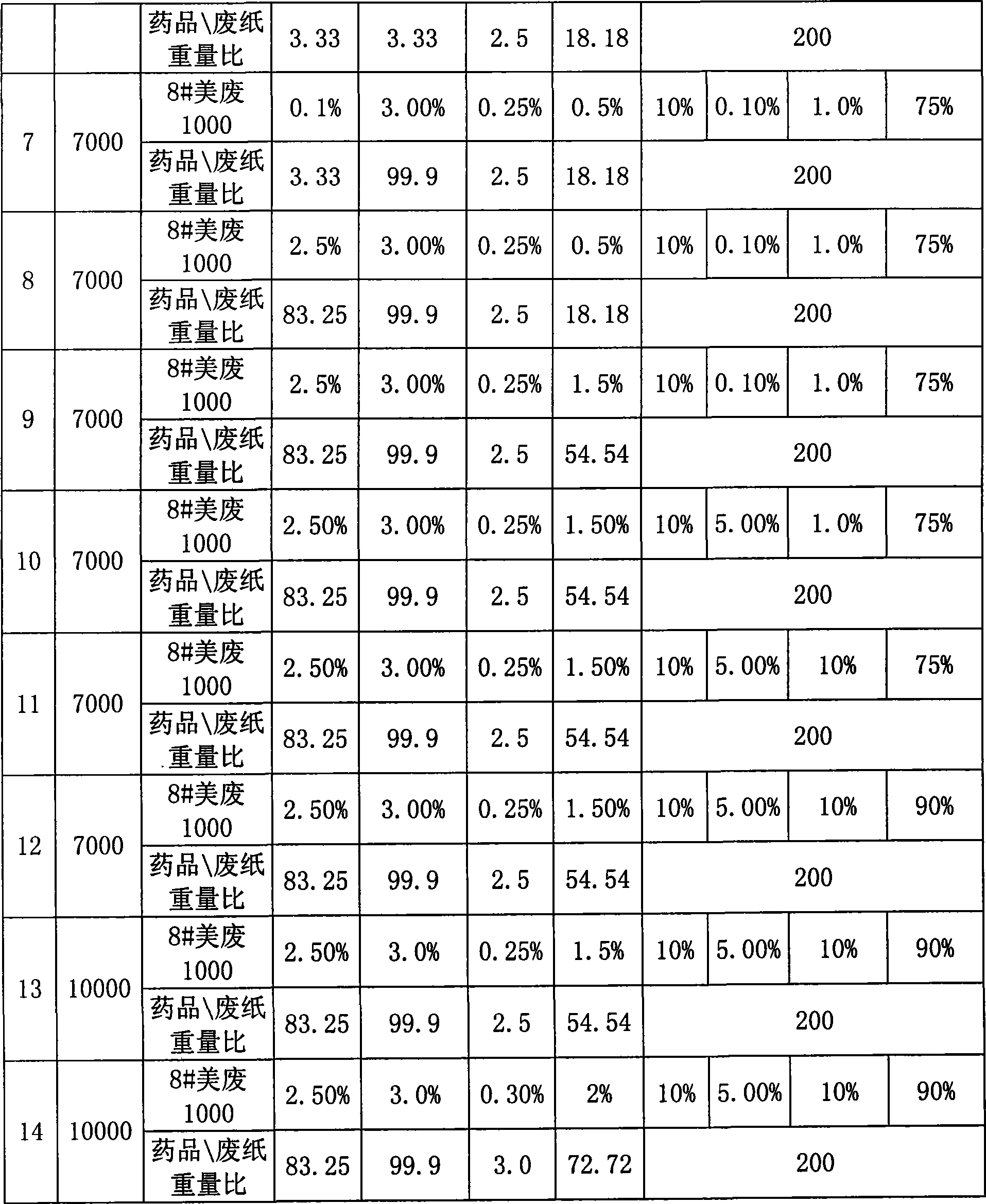

[0033] Carry out waste paper deinking through the following steps in sequence, and the deinking effect is shown in Table 1:

[0034] (1), add 7000ml of 80 ℃ hot water in the hydropulper;

[0035] (2), sequentially add concentration is 30%, specific gravity is 33.3ml of liquid caustic soda of 1.35 ± 2g / l; Baume degree ≥ ° Be`38, modulus is 16.5ml of liquid sodium silicate of 3.0~4.5; Concentration is 50%, ISO whiteness 80%, effective alkali content 0.5%, hydrochloric acid insoluble matter content 5% alkali recovery lime mud 80g and Greenfell liquid cultural paper deinking agent 2.5g;

[0036] (3), drop into 37# American waste in the hydraulic pulper -- a kind of waste cultural paper 1000g that is specially used for deinking and bleaching, disintegrate 10min;

[0037] (4), then add 36.36ml of hydrogen peroxide with a concentration of 27.5%, and then disintegrate for 25 minutes;

[0038] Flotation deinking is then performed using a conventional flotation deinking system. Final...

Embodiment 2

[0042] Carry out waste paper deinking through the following steps in turn, and the deinking effect is shown in Table 2:

[0043] (1), add 7000ml of 80 ℃ hot water in the hydropulper;

[0044] (2), successively adding concentration is 30%, specific gravity is 33.3ml of liquid caustic soda of 1.35 ± 2g / l; Baume degree ≥ ° Be`38, modulus is 16.65ml of liquid sodium silicate of 3.0~4.5; Concentration is 50%, ISO whiteness 80 degrees, effective alkali content 0.5%, hydrochloric acid insoluble matter content 5% alkali recovery lime mud 60g and Greenfell liquid cultural paper deinking agent 2.5g;

[0045] (3), drop into 37# American waste in the hydraulic pulper -- a kind of waste cultural paper 1000g that is specially used for deinking and bleaching, disintegrate 10min;

[0046] (4), then add 36.36ml of hydrogen peroxide with a concentration of 27.5%, and then disintegrate for 25 minutes;

[0047] Flotation deinking is then performed using a conventional flotation deinking system....

Embodiment 3

[0051] The waste paper is deinked through the following steps in sequence, and the deinking effect is shown in Table 3:

[0052] (1), add 8000ml of 80 ℃ hot water in the hydropulper;

[0053] (2), successively adding concentration is 30%, specific gravity is 33.3ml of liquid caustic soda of 1.35 ± 2g / l; Baume degree ≥ ° Be`38, modulus is 16.65ml of liquid sodium silicate of 3.0~4.5; Concentration is 50%, ISO whiteness 90 degrees, effective alkali content 0.1%, hydrochloric acid insoluble matter content 1% alkali recovery lime mud 80g and Greenfell liquid newsprint paper paper deinking agent 2.5g;

[0054] (3), drop into 8# American waste in the hydropulper -- a kind of waste newspaper 1000g that is specially used in deinking and bleaching, disintegrate 10min;

[0055] (4), then add 36.36ml of hydrogen peroxide with a concentration of 27.5%, and then disintegrate for 25 minutes;

[0056] Flotation deinking is then performed using a conventional flotation deinking system. Fin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com