Jumper forming machine and forming method thereof

A molding method and molding machine technology, applied in circuit/collector parts, electrical components, circuits, etc., can solve problems such as difficulty in ensuring uniform product specifications and dimensions, complex equipment structure, and expensive purchase costs, etc. The effect of high precision, improved production efficiency, and reduced manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the embodiments and accompanying drawings, and the contents mentioned in the embodiments are not intended to limit the present invention.

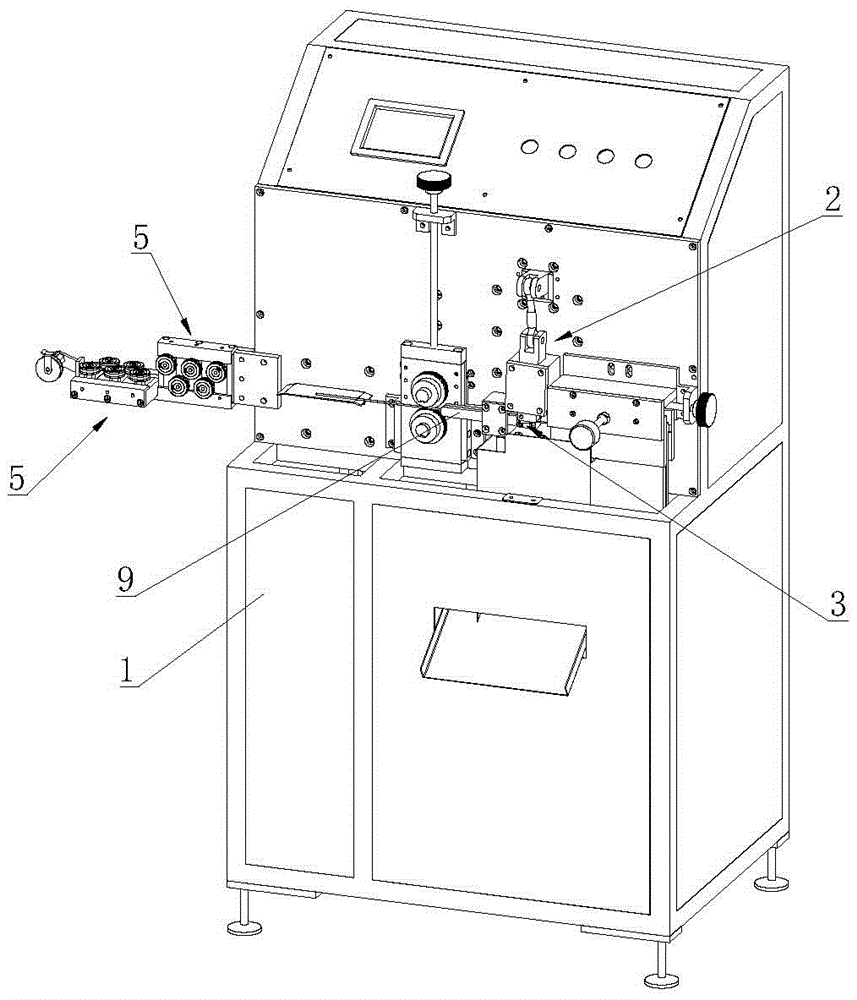

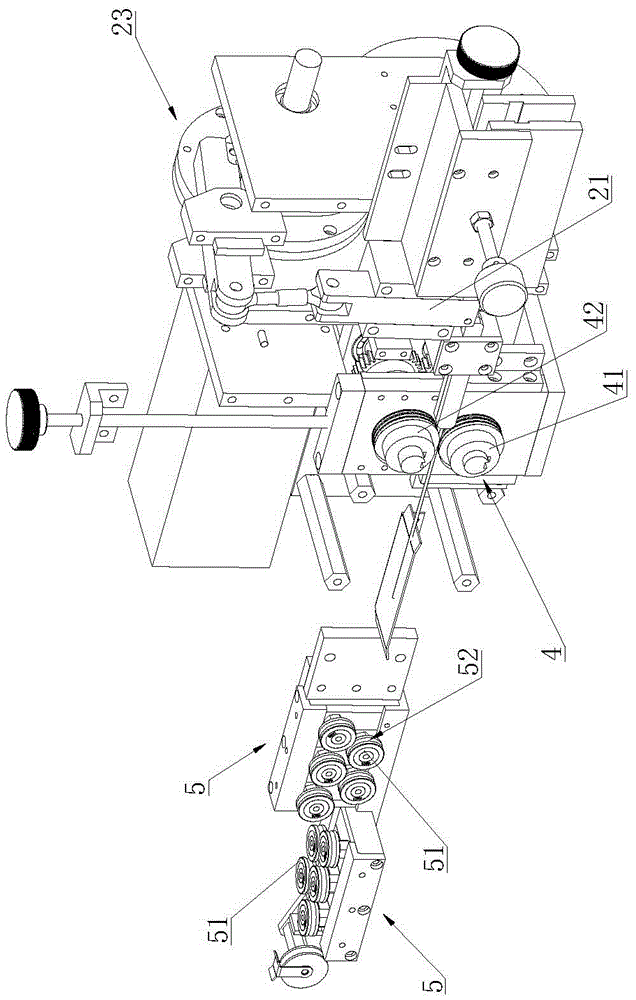

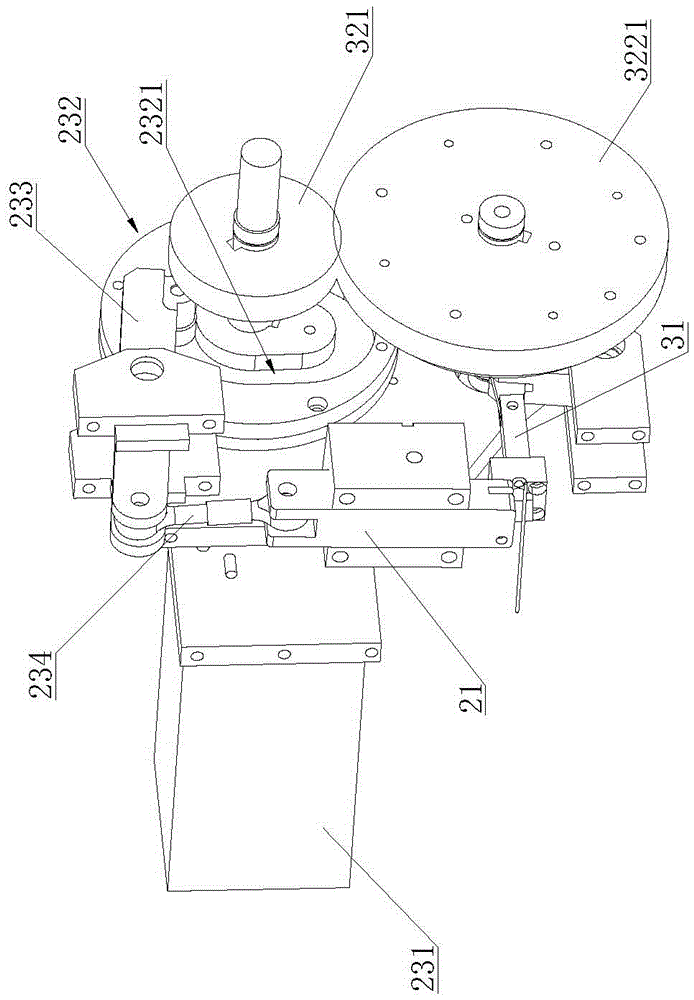

[0028] Such as Figure 1 to Figure 6 As shown, the present invention provides a jumper forming method, comprising the following steps:

[0029] a. Use the feeding mechanism to move the wire out of the required pin length in front of the forming mold;

[0030] b. Punching the wire rod in step a with a molding die to obtain the first pin portion 01;

[0031] c. Using a feeding mechanism to send the wire in step b to the required connection length in front of the forming mold;

[0032] d. Punching the wire rod in step c with a molding die to obtain the connection part 02;

[0033] e. Use the feeding mechanism to move the wire in step d to the length of the pin required in front of the cutter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com