Renewable high-strength corrugated medium and its production method

A production method and technology of corrugated base paper, applied in the field of pulp and papermaking, can solve the problems of insufficient utilization of pulp residue, easy pollution of the environment, high raw material prices, etc., and achieve the effects of reducing papermaking costs, being conducive to environmental protection, and good environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Example 1 Preparation of high-strength corrugated base paper

[0026] Raw materials: 90% of national waste, 10% of pulp residue

[0027] Put the waste paper into the hydraulic pulper to disintegrate. After the disintegration, the slag is removed by the high-concentration desander and then enters the classifying screen. It is classified into two kinds of fibers: long fiber and short fiber. The classification ratio of long fiber and short fiber is 5 :5. The long fibers are processed by four-stage heavy desander, three-stage fine screen, and two-stage light desander. After being concentrated by multiple discs, they are sent to double disc mills for beating to make long fiber slurry with a beating degree of 35°SR; After being treated by three-stage heavy desander and light desander, short fiber slurry is made after multi-disk concentration;

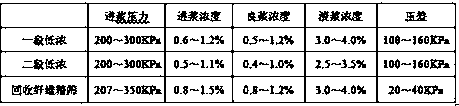

[0028] The tailings of the desander are processed by the first-stage and second-stage low-concentration desanders to remove impuri...

Embodiment 2

[0030] Example 2 Preparation of high-strength corrugated base paper

[0031] Raw materials: 40% of national waste, 60% of pulp residue

[0032] Put the waste paper into the hydraulic pulper to disintegrate. After the disintegration, the slag is removed by the high-concentration desander and then enters the classifying screen. It is classified into two kinds of fibers: long fiber and short fiber. The classification ratio of long fiber and short fiber is 5 :5. The long fiber is processed by four-stage heavy desander, three-stage fine screen, and two-stage light desander. After multi-disk concentration, it is sent to double-disc mill for beating to make long fiber slurry with a beating degree of 32°SR; short fiber After being treated by three-stage heavy desander and light desander, short fiber slurry is made after multi-disk concentration;

[0033] The tailings of the desander are processed by the first-stage and second-stage low-concentration desanders to remove impurities,...

Embodiment 3

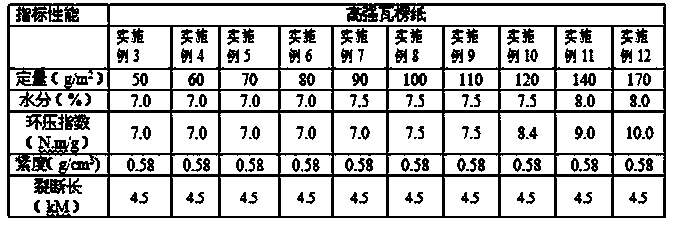

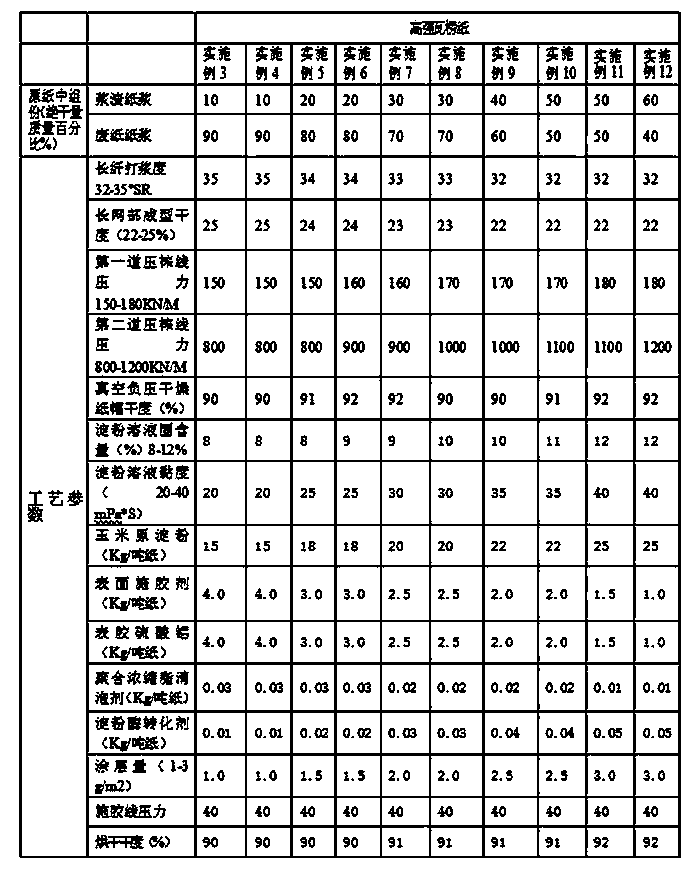

[0035] Example 3 Preparation of high-strength corrugated paper

[0036] Raw materials: 90% of national waste, 10% of pulp residue

[0037] Put the waste paper into the hydraulic pulper to disintegrate. After the disintegration, the slag is removed by the high-concentration desander and then enters the classifying screen. It is classified into two kinds of fibers: long fiber and short fiber. The classification ratio of long fiber and short fiber is 5 :5. The long fibers are processed by four-stage heavy desander, three-stage fine screen, and two-stage light desander. After being concentrated by multiple discs, they are sent to double disc mills for beating to make long fiber slurry with a beating degree of 35°SR; After being treated by three-stage heavy desander and light desander, short fiber slurry is made after multi-disk concentration;

[0038] The tailings of the desander are processed by the first-stage and second-stage low-concentration desanders to remove impurities...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com