Paper with coffee flavor and preparation method and application thereof

A technology for aroma and coffee, applied in the field of paper with coffee aroma and its preparation, to achieve the effects of reducing usage, improving physical and mechanical strength, and reducing papermaking costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The present invention provides a method for preparing coffee-flavored paper according to the above technical solution, which includes the following steps:

[0031] Mix the pulp fiber, waste paper scraps, coffee grounds and water to obtain the original pulp liquid after beating;

[0032] Mixing the pulp stock solution with an adsorbent, and then sequentially performing dilution and charge balancing treatments to obtain a shaped slurry;

[0033] Using a vacuum suction method to shape the molding slurry to obtain a molding paper blank;

[0034] The formed paper blank is subjected to hot press forming to obtain paper with coffee aroma.

[0035] In the present invention, pulp fiber, waste paper scraps, coffee grounds and water are mixed, and the pulp liquid is obtained after beating. The present invention has no special requirements on the amount of water, and a pulp stock solution with a mass concentration of 8-12% can be obtained; the mass concentration of the pulp stock solution i...

Embodiment 1

[0042] a. Mix corn flour, cassava flour and vinyl acetate with water in a mass ratio of 50:50:3 (the mixture is based on 100 parts by mass, and the water accounts for 80-85%), and the total mass of raw materials is 25kg at 80°C. Stir for 30 minutes to obtain adsorbent;

[0043] b. Put 1000kg of water into the beating barrel and add 20kg waste paper scraps (white paper edge), 70kg pulp fiber (i.e. natural raw wood pulp), 10kg coffee grounds, and continue beating for 45min at 900r / min to make the pulp The fiber and coffee ions are fully combined, and 25kg of the adsorbent prepared above is added, and the pulp stock solution is obtained after uniform mixing;

[0044] c. Pour the pulp stock solution into the mixing tank, add 9000kg of clean water to dilute (the mass concentration after dilution can be controlled within the range of 1 to 1.5%), then test the charge of the diluted slurry, and add a charge balance agent according to the test results to make the pulp When the material is ...

Embodiment 2~3

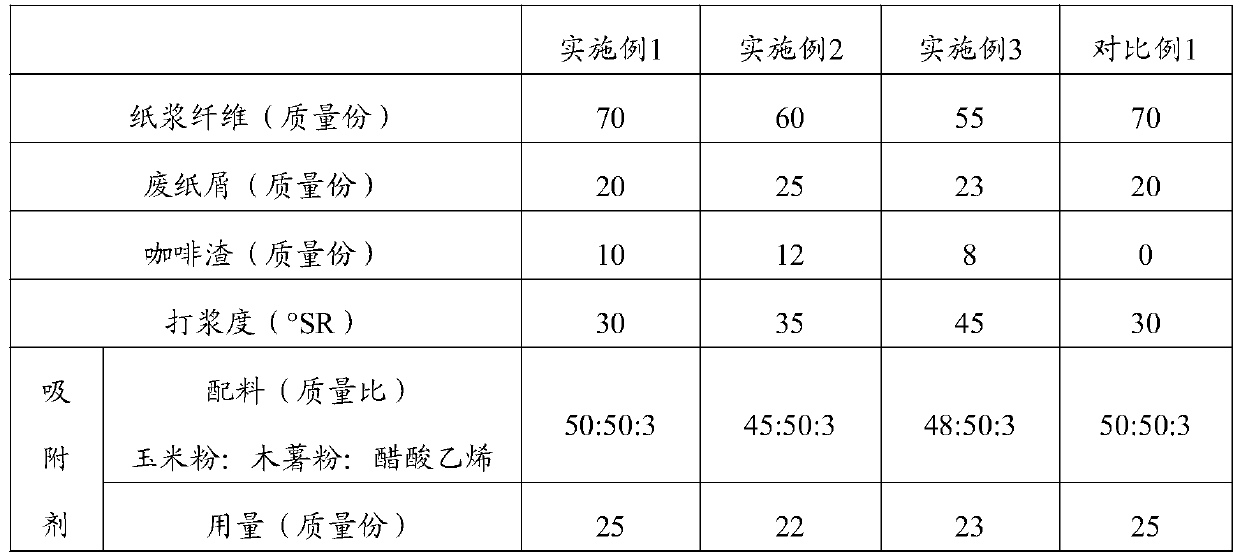

[0048] The coffee-flavored paper was prepared according to the method of Example 1, and the amount of raw materials is shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com