Method for producing high-strength corrugating medium paper through blending of leather waste and OCC waste paper

A technology of leather waste and corrugated medium paper, applied in pulp beating/refining method, small raw hide/large raw hide/leather/fur treatment, small raw hide/large raw hide/leather skin/fur chemical treatment, etc., can solve environmental pollution , waste of resources and other issues, to achieve the effect of low production cost, high production efficiency and avoiding environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

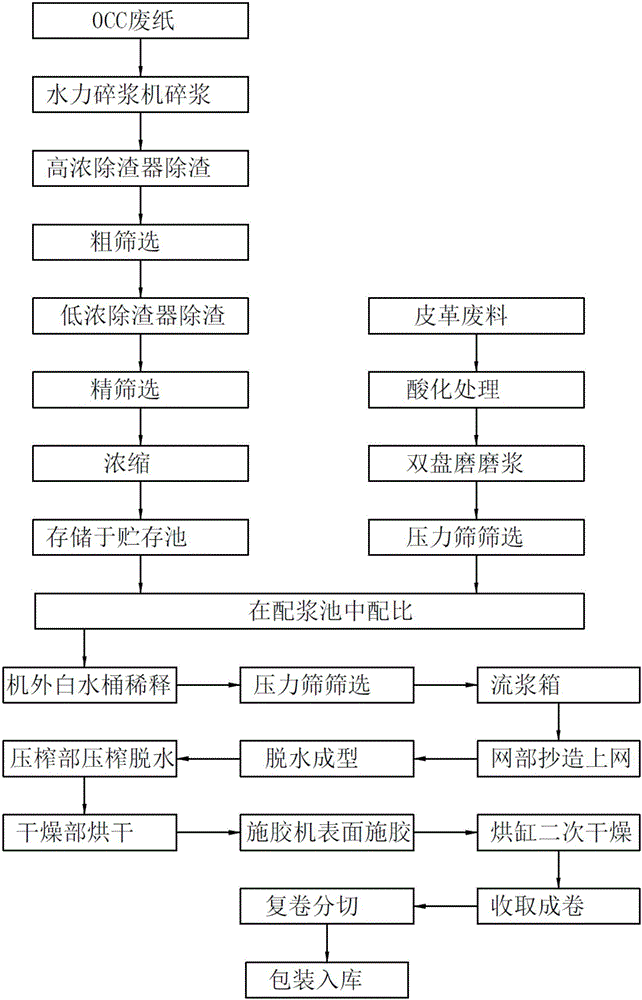

[0040] Embodiment, a method for producing high-strength corrugated medium paper by mixing leather waste with OCC waste paper, figure 1 shown, including the following processing steps,

[0041] Acidification treatment steps of leather waste, use acid hydrolysis method to acidify leather waste, choose concentrated acid in the acid hydrolysis method, concentrated acid chooses concentrated sulfuric acid, concentrated nitric acid or concentrated hydrochloric acid, the treatment concentration of the acid hydrolysis method is 10%, and the pH value is 1 ~2. Collagen fibers are separated from leather waste, and most of the separated collagen fibers exist in the form of fiber bundles. The high-concentration hydrogen ions in concentrated acid are combined with the carboxyl groups of collagen fibers to obtain a first-grade material.

[0042] Mechanical treatment steps of leather waste: use double disc mill to mechanically refine the primary material. During the refining process, all the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com