High-efficiency benzene acrylic antibacterial multipolymer emulsion type surface sizing agent and preparation method thereof

A technology of polymer emulsion and surface sizing agent, applied in the direction of water-repellent addition, etc., can solve the problems of poor printing suitability, poor paper strength, low sizing degree, etc., achieve significant killing effect, improve Cobb value, low foaming effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] ① Preparation of dispersant

[0039] Prepared by mixing 75 g of cationic starch solution with a mass concentration of 25% and 25 g of isopropanol;

[0040] ② Preparation of seed emulsion

[0041] Take 0.2 parts of styrene, 0.01 parts of n-butyl acrylate, 0.01 parts of methyl methacrylate, 0.06 parts of C 18 Quaternary ammonium salt type cationic gemini emulsifier, 0.2 part of acetoacetoxyethyl methacrylate, 0.3 part of dispersant, 0.03 part of initiator azobisisobutylamidine hydrochloride and 39 parts of deionized water are added to the Put it in a 1000mL four-neck flask with a device, a constant flow dropping device, a stirrer and a thermometer, stir and mix evenly, then raise the temperature, maintain 65°C under the protection of nitrogen to carry out free radical seed emulsion polymerization, and react for 20 minutes to obtain the product;

[0042] ③ Preparation of pre-emulsion

[0043] Take 3.8 parts of styrene, 0.2 parts of n-butyl acrylate, 0.18 parts of methyl...

Embodiment 2

[0048] ① Preparation of dispersant

[0049] Prepared by mixing 95 g of cationic guar gum solution with a mass concentration of 45% and 5 g of isopropanol;

[0050] ② Preparation of seed emulsion

[0051] Take 5.6 parts of styrene, 1.4 parts of butyl acrylate, 1 part of methyl methacrylate, 4.5 parts of C 16 Quaternary ammonium salt type cationic gemini emulsifier, 2.5 parts of diacetone acrylamide, 3 parts of dispersant, 1.8 parts of initiator azobisisobutylamidine hydrochloride and 68 parts of deionized water are added to the Add dropwise device, stirrer, and thermometer into a 1000mL four-neck flask, stir and mix evenly, then raise the temperature, maintain 85°C under nitrogen protection, carry out free radical seed emulsion polymerization, and react for 20 minutes to obtain the product;

[0052] ③ Preparation of pre-emulsion

[0053] Take 22.4 parts of styrene, 6.6 parts of n-butyl acrylate, 3 parts of methyl methacrylate, 0.5 parts of C 16 Quaternary ammonium salt type...

Embodiment 3

[0058] ① Preparation of dispersant

[0059] Prepared by mixing 80 g of cationic guar gum solution with a mass concentration of 30% and 20 g of isopropanol;

[0060] ② Preparation of seed emulsion

[0061] Take 1.4 parts of styrene, 0.3 parts of n-butyl acrylate, 0.3 parts of methyl methacrylate, 3.0 parts of C 12 Quaternary ammonium salt type cationic gemini emulsifier, 2 parts of glycidyl acrylate, 2 parts of dispersant, 0.09 parts of initiator azobisisobutylamidine hydrochloride and 52 parts of deionized water are added to the Add dropwise device, stirrer, and thermometer to a 1000mL four-necked flask, stir and mix evenly, then raise the temperature, and maintain 75°C under nitrogen protection to carry out free radical seed emulsion polymerization; react for 20 minutes to obtain the product;

[0062] ③ Preparation of pre-emulsion

[0063] Take 23.6 parts of styrene, 5.4 parts of n-butyl acrylate, 4 parts of methyl methacrylate, 1.0 parts of C 12 Quaternary ammonium salt ...

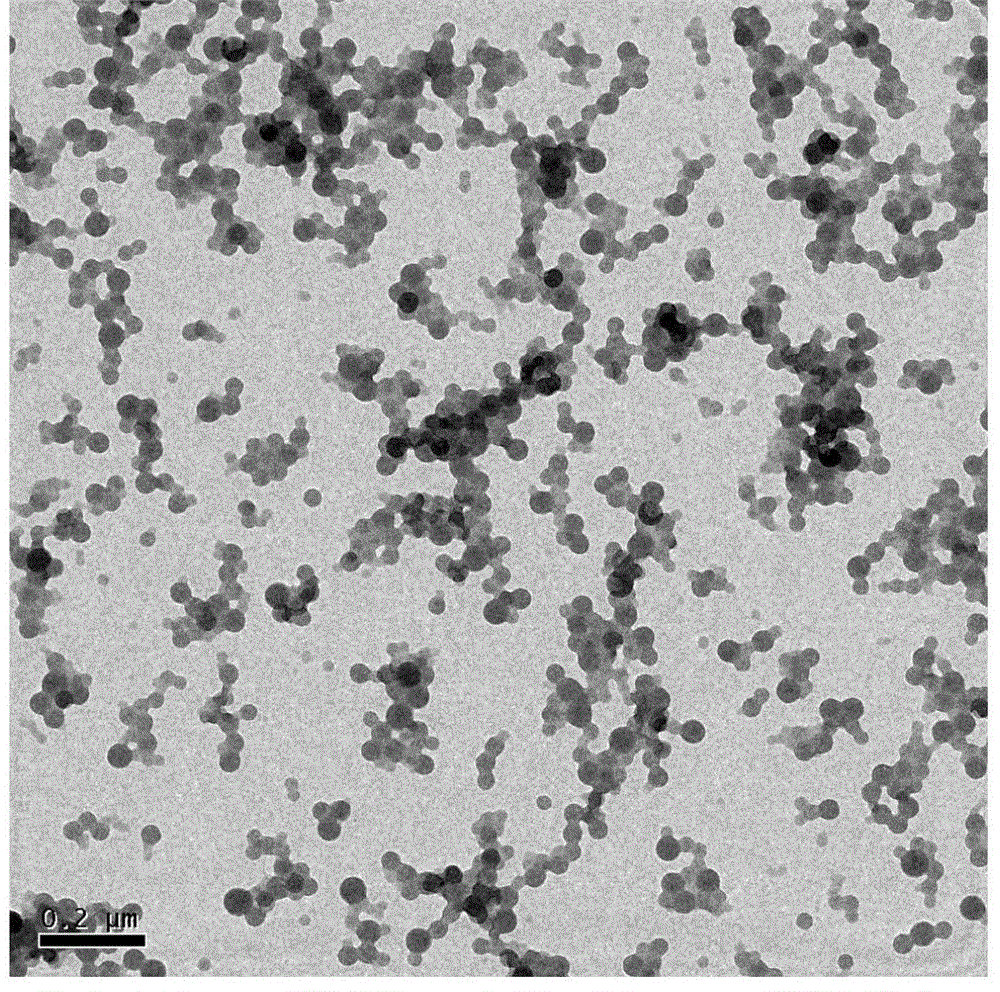

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com