Preparation method of surface sizing agent for starch-based papermaking

A surface sizing agent, starch-based technology, used in papermaking, textiles and papermaking, paper coatings, etc., can solve the problems of poor mechanical properties and barrier properties of starch-based surface sizing agents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

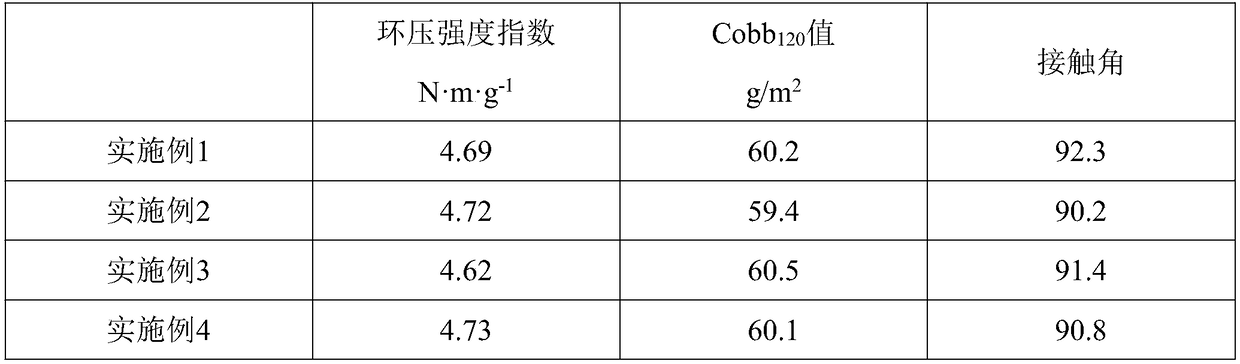

Examples

Embodiment 1

[0016] A preparation method of starch-based papermaking surface sizing agent, comprising the following steps:

[0017] Step 1, in parts by weight, mix 100 parts of cornstarch, 2 parts of amylase and 50 parts of water, heat to 50 ° C, react for 30 minutes, then add 10 parts of formaldehyde, 10 parts of urea, 5 parts of alkaline catalyst, and heat up to 70°C, react for 60 minutes, let cool, and obtain a starch-based copolymer;

[0018] Step 2, in parts by weight, mix 100 parts of corn starch, 3 parts of accelerator, 5 parts of lignin, 5 parts of titanium dioxide particles, 2 parts of carboxymethyl chitosan, and 40 parts of water, heat up to 80°C, and react for 50 minutes , let cool to obtain oxidized cornstarch paste;

[0019] In step 3, the starch-based copolymer obtained in step 1 is mixed with the oxidized corn starch paste obtained in step 2 to obtain the product.

[0020] Wherein, the basic catalyst is potassium hydroxide, the accelerator is potassium persulfate, and the ...

Embodiment 2

[0024] A preparation method of starch-based papermaking surface sizing agent, comprising the following steps:

[0025] Step 1, in parts by weight, mix 100 parts of cornstarch, 3 parts of amylase and 60 parts of water, heat to 55 ° C, react for 30 minutes, then add 15 parts of formaldehyde, 13 parts of urea, 6 parts of alkaline catalyst, and heat up to 75°C, react for 40 minutes, let cool, and obtain a starch-based copolymer;

[0026] Step 2, in parts by weight, mix 100 parts of corn starch, 5 parts of accelerator, 7 parts of lignin, 6 parts of titanium dioxide particles, 3 parts of carboxymethyl chitosan, and 50 parts of water, heat up to 85 ° C, and react for 40 minutes , let cool to obtain oxidized cornstarch paste;

[0027] In step 3, the starch-based copolymer obtained in step 1 is mixed with the oxidized corn starch paste obtained in step 2 to obtain the product.

[0028] Wherein, the basic catalyst is potassium hydroxide, the accelerator is potassium persulfate, and th...

Embodiment 3

[0032] A preparation method of starch-based papermaking surface sizing agent, comprising the following steps:

[0033] Step 1, in parts by weight, mix 100 parts of cornstarch, 3 parts of amylase and 70 parts of water, heat to 60 ° C, react for 30 minutes, then add 17 parts of formaldehyde, 15 parts of urea, 8 parts of alkaline catalyst, and heat up to 80°C, react for 50 minutes, let cool, and obtain a starch-based copolymer;

[0034] Step 2, in parts by weight, mix 100 parts of corn starch, 5 parts of accelerator, 8 parts of lignin, 7 parts of titanium dioxide particles, 4 parts of carboxymethyl chitosan, and 50 parts of water, heat up to 85 ° C, and react for 40 minutes , let cool to obtain oxidized cornstarch paste;

[0035] In step 3, the starch-based copolymer obtained in step 1 is mixed with the oxidized corn starch paste obtained in step 2 to obtain the product.

[0036] Wherein, the basic catalyst is potassium hydroxide, the accelerator is potassium persulfate, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com