White paperboard and method for manufacturing same

A technology of whiteboard and pulp, which is applied in papermaking, pulp bleaching, textiles and papermaking, etc. It can solve the problems that whiteboard paper is not easy to fluff, low formaldehyde content, and ink is easy to adhere, so as to save the process of sterilization and transparency of finished paper Low, smoothness-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

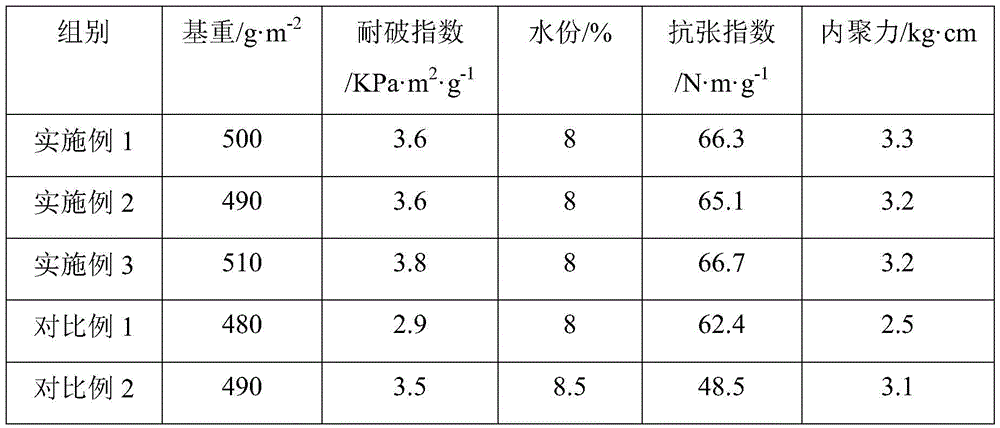

Examples

Embodiment 1

[0031] A kind of white board paper is made from the following raw materials in parts by weight: 85 parts of mixed fiber, 6 parts of persimmon peel extract and 15 parts of semichemical pulp. Wherein, 85 parts of the mixed fibers include mango tree fiber and bamboo fiber with a mass ratio of 15:2, and the length of the mango tree fiber is 0.85 mm and the width is 0.02 mm.

[0032] The preparation method of the persimmon skin extract is as follows: dry and pulverize the persimmon skin, add it to an aqueous solution of acetone to avoid light and reflux for extraction, filter after the first extraction, perform 2 times of reflux extraction on the filter residue, and 3 times of reflux to extract The filtrates were combined, the acetone was removed by distillation under reduced pressure, and the filtrate was concentrated and freeze-dried to obtain final product; wherein, the amount of acetone added each time was 3 times that of the persimmon skin quality.

[0033] The raw material of...

Embodiment 2

[0044] A white board paper is made from the following raw materials in parts by weight: 95 parts of mixed fiber, 8 parts of persimmon peel extract and 22 parts of semichemical pulp. Wherein, 95 parts of the mixed fibers include mango tree fiber and bamboo fiber with a mass ratio of 16:3, and the length of the mango tree fiber is 0.85 mm and the width is 0.02 mm.

[0045] The preparation method of the persimmon skin extract is as follows: dry and pulverize the persimmon skin, add it to an aqueous solution of acetone to avoid light and reflux for extraction, filter after the first extraction, perform 2 times of reflux extraction on the filter residue, and 3 times of reflux to extract The filtrates were combined, the acetone was removed by distillation under reduced pressure, and the filtrate was concentrated and freeze-dried to obtain final product; wherein, the amount of acetone added each time was 5 times that of the persimmon skin quality.

[0046] The raw material of the whi...

Embodiment 3

[0057] A kind of white board paper is made from the following raw materials in parts by weight: 90 parts of mixed fiber, 7 parts of persimmon peel extract and 18 parts of semichemical pulp. Wherein, 90 parts of the mixed fibers include mango tree fiber and bamboo fiber with a mass ratio of 15:2, and the length of the mango tree fiber is 0.85 mm and the width is 0.02 mm.

[0058] The preparation method of the persimmon skin extract is as follows: dry and pulverize the persimmon skin, add it to an aqueous solution of acetone to avoid light and reflux for extraction, filter after the first extraction, perform 2 times of reflux extraction on the filter residue, and 3 times of reflux to extract The filtrates were combined, the acetone was removed by distillation under reduced pressure, and the filtrate was concentrated and freeze-dried to obtain final product; wherein, the amount of acetone added each time was 4 times that of the persimmon skin quality.

[0059] The raw material of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| free rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com