Adhesive for copper-clad plates suitable for automobiles, and preparation method thereof

A copper clad laminate and adhesive technology, applied in the direction of adhesive types, polymer adhesive additives, non-polymer adhesive additives, etc., can solve the difficult production and processing of polyphenylene ether system and high product cost problem, to achieve the effect of good machinability, low water absorption, and reduced curing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

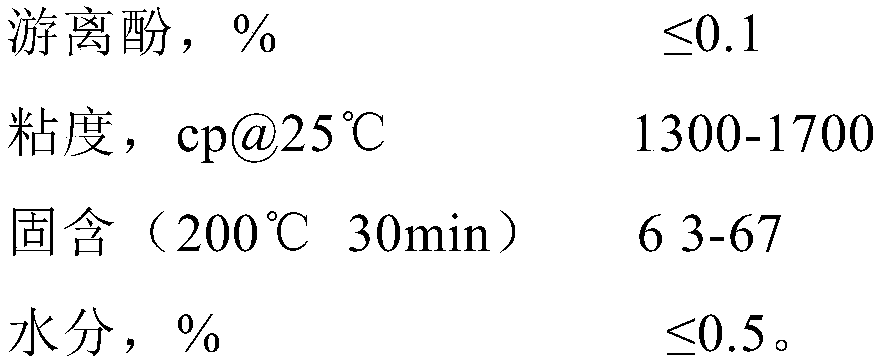

[0050] 1. Prepare materials according to the formula composition

[0051] Material name

Example 1

Brominated modified epoxy resin (%)

35

Isocyanate-modified epoxy resin (%)

25

Novolac resin

35

Amine curing agent

5

2-Ethyl-4 methylimidazole

0.05

Inorganic filler (%)

20

Silane (%)

0.12

Organic solvents(%)

30

Toughening agent (%)

13

[0052] 2. Glue adjustment

[0053] 2.1 Add organic solvent, silane, and 2-ethyl-4-methylimidazole to the stirring tank in sequence according to the amount of the formula, turn on the high-speed stirrer at a speed of 1200 rpm, keep the temperature of the tank at 45°C, and continue stirring for 30 minutes after the addition is complete;

[0054] 2.2 Add brominated-modified epoxy resin, isocyanate-modified epoxy resin, novolac resin, and toughening agent in sequence according to the formula amount in the stirring tank and stir for 150 minutes at ...

Embodiment 2

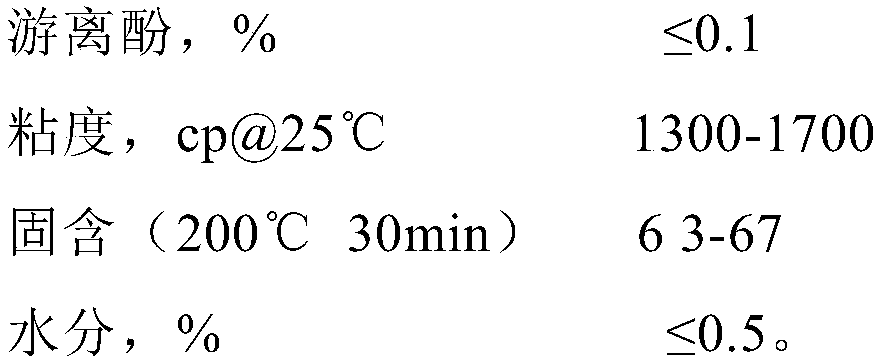

[0071] 1. Prepare materials according to the formula composition

[0072] Material name

Example 2

Brominated modified epoxy resin (%)

15

Isocyanate-modified epoxy resin (%)

35

Novolac resin

49

Amine curing agent

1

2-Ethyl-4 methylimidazole

0.02

Inorganic filler (%)

50

Silane (%)

0.25

Organic solvents(%)

50

Toughening agent (%)

5

[0073] 2. Glue adjustment

[0074] 2.1 Add organic solvent, silane, and 2-ethyl-4-methylimidazole into the mixing tank in sequence according to the formula amount, turn on the high-speed stirrer, rotate at 1300 rpm, keep the tank temperature at 35°C, and continue stirring for 50 minutes after the addition is complete;

[0075] 2.2 Add brominated-modified epoxy resin, isocyanate-modified epoxy resin, novolac resin, and toughening agent in sequence according to the formula amount in the stirring tank and stir for 170 minutes at a speed of 1100 rp...

Embodiment 3

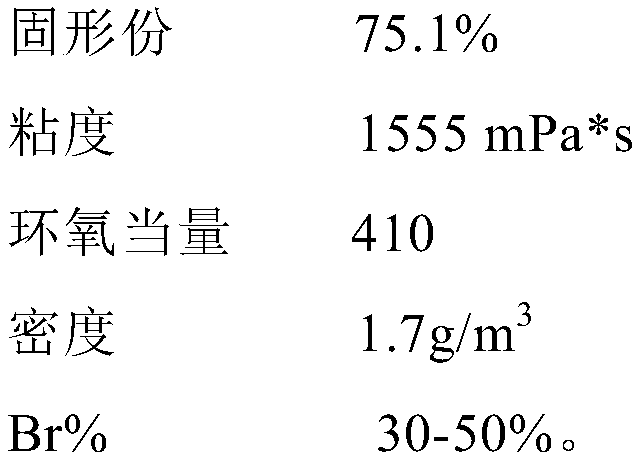

[0092] 1. Prepare materials according to the formula composition

[0093]

[0094]

[0095] 2. Glue adjustment

[0096] 2.1 Add organic solvent, silane, and 2-ethyl-4-methylimidazole to the stirring tank in sequence according to the formula amount, turn on the high-speed stirrer, rotate at 1100 rpm, keep the tank temperature at 30°C, and continue stirring for 70 minutes after the addition is complete;

[0097] 2.2 Add brominated-modified epoxy resin, isocyanate-modified epoxy resin, novolac resin, and toughening agent in sequence according to the formula amount in the stirring tank and stir for 120 minutes at a speed of 1400 rpm;

[0098] 2.3 Weigh the inorganic filler according to the formula, add it into the stirring tank and stir for 2 hours at a speed of 1300 rpm, and then the adhesive is prepared.

[0099] 3. Glue and bake

[0100] The adhesive made by impregnating 7628 type E-glass glass fiber cloth is selected, and the semi-cured adhesive sheet is prepared by gl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com