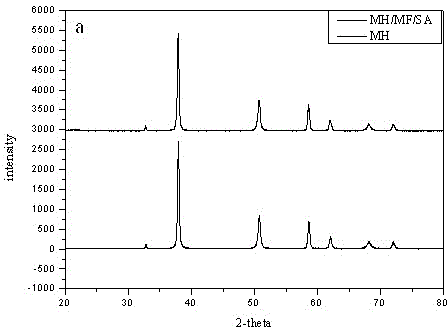

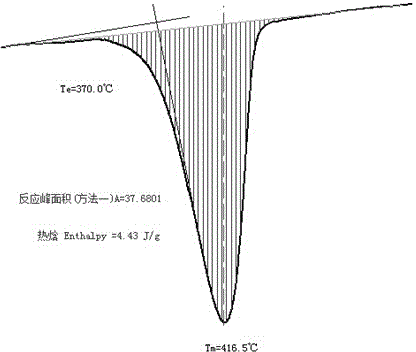

Double-covered magnesium hydroxide fire retardant and preparation method thereof

A magnesium hydroxide and flame retardant technology, applied in the field of flame retardants, can solve the problems of easy abrasion of magnesium hydroxide microcapsule powder particles, and achieve the effects of good dispersion, integrity and thermal stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

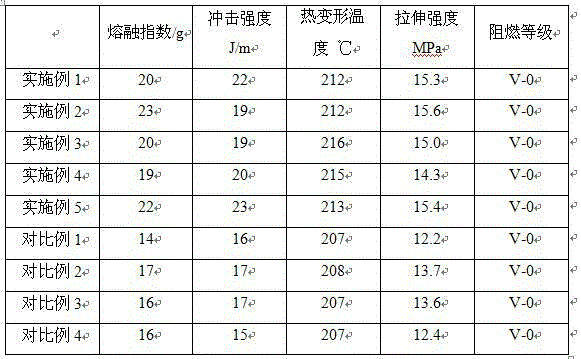

Examples

Embodiment 1

[0034] (1) Weigh 120g of melamine and 30g of formaldehyde into a 2L reaction kettle with 1L of distilled water, adjust the pH to 9 with sodium hydroxide solution as the pH regulator, set the reaction temperature to 75°C, and the stirring speed to 600r / min, reaction 1h to solution is colorless, obtains prepolymer;

[0035] (2) Use acetic acid as the pH regulator to adjust the pH of the prepolymer solution to 5; weigh 385g of magnesium hydroxide powder, add it to the prepolymer solution, and stir for 2 hours, the stirring speed is 600r / min, and the temperature is controlled At 75°C, magnesium hydroxide melamine formaldehyde resin microcapsule suspension was prepared;

[0036] (3) Filter the microcapsule suspension and wash it with ethanol, then dry it in a constant temperature drying oven at 105°C for 10 hours, cool to room temperature, and grind the prepared magnesium hydroxide melamine formaldehyde resin microcapsules into powder;

[0037] (4) Weigh 80g of stearic acid and a...

Embodiment 2

[0042] (1) Weigh 120g of melamine and 30g of formaldehyde into a 2L reaction kettle with 1L of distilled water, adjust the pH to 8.5 with sodium hydroxide solution as the pH regulator, set the reaction temperature to 80°C, and the stirring speed to 400r / min, reaction 1.5h to solution is colorless, obtains prepolymer;

[0043] (2) Use acetic acid as the pH regulator to adjust the pH of the prepolymer solution to 4.5; weigh 230g of magnesium hydroxide powder, add it to the prepolymer solution, and stir for 0.5h at a stirring speed of 700r / min. Controlling 75°C to prepare magnesium hydroxide melamine formaldehyde resin microcapsule suspension;

[0044] (3) Filter the microcapsule suspension and wash it with ethanol, then dry it in a constant temperature drying oven at 105°C for 8 hours, cool to room temperature, and grind the prepared magnesium hydroxide melamine formaldehyde resin microcapsules into powder;

[0045] (4) Weigh 80g of stearic acid and add it into a 2L reaction k...

Embodiment 3

[0050] (1) Weigh 120g of melamine and 30g of formaldehyde into a 2L reaction kettle with 1L of distilled water, adjust the pH to 9.5 with sodium hydroxide solution as the pH regulator, set the reaction temperature to 85°C, and the stirring speed to 400r / min, reaction 1.5h to solution is colorless, obtains prepolymer;

[0051] (2) Use acetic acid as a pH regulator to adjust the pH of the prepolymer solution to 5.5; weigh 500g of magnesium hydroxide powder, add it to the prepolymer solution, and stir for 2.5h at a stirring speed of 700r / min. Control 80 ℃ to prepare magnesium hydroxide melamine formaldehyde resin microcapsule suspension;

[0052] (3) Filter the microcapsule suspension and wash it with ethanol, then dry it in a constant temperature drying oven at 105°C for 16 hours, cool to room temperature, and grind the prepared magnesium hydroxide melamine formaldehyde resin microcapsules into powder;

[0053] (4) Weigh 100g of stearic acid and add it into a 2L reaction kettl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com