Sesbania gum organic titanium surface crosslinking modified precipitated calcium carbonate, preparation method and application thereof and paper

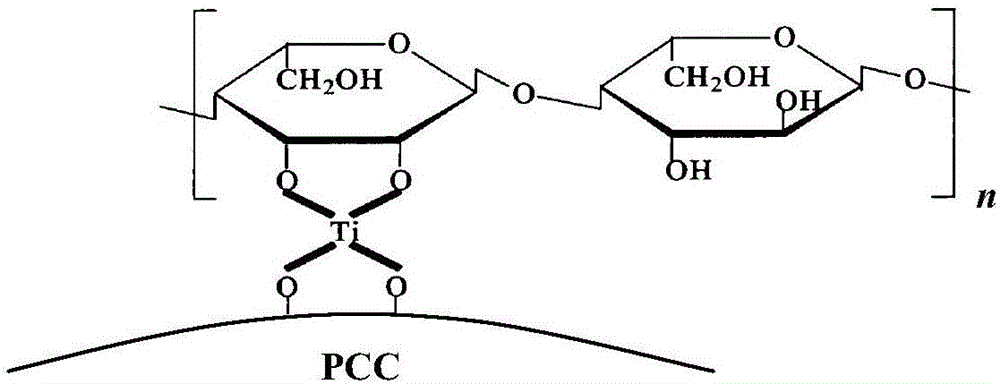

A technology of precipitated calcium carbonate and cross-linking modification, which is applied in textiles and papermaking, chemical instruments and methods, dyeing low-molecular organic compound treatment, etc. It can solve the problems of reducing application effect and not very firm combination, and achieve retention rate Improvement, smooth paper surface and excellent application performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Step 1: Add 1.25% (relative to the amount of PCC added) squat gum into the three-hole oblique mouth containing 90g of water, raise the temperature to 80°C, stir and disperse at 400rpm, and then add 10g of precipitated calcium carbonate;

[0047] Step 2: Add 0.5% (relative to the amount of PCC) bistriethanolamine diisopropyl titanate into the reactor, and stir for 75 minutes;

[0048] Step 3: collecting the reaction product by centrifugation and washing and drying it;

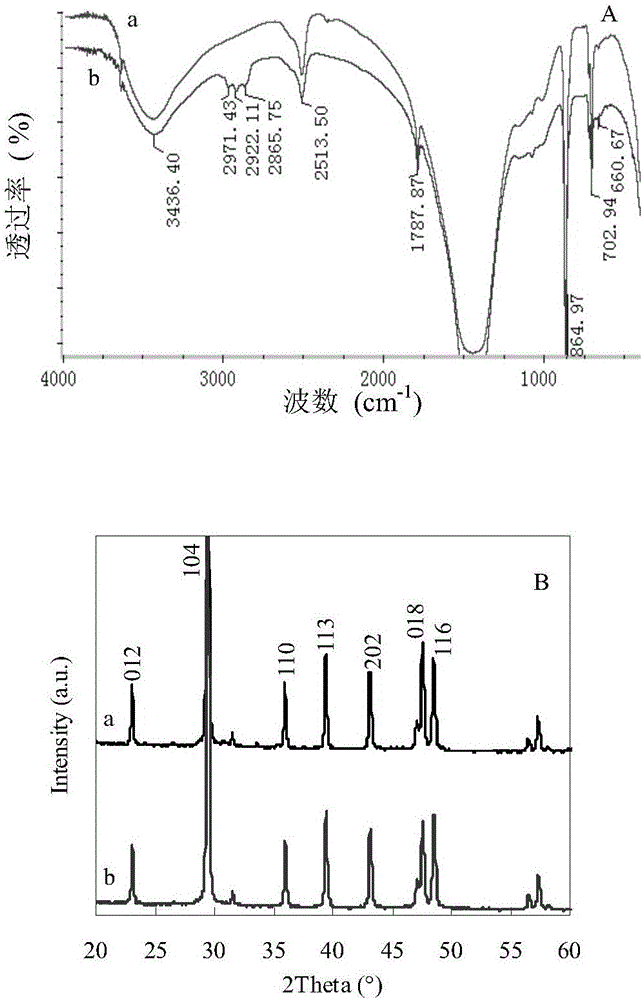

[0049] Step 4: Grind the modified precipitated calcium carbonate and the precipitated calcium carbonate finely with a mortar, pass through a 200-mesh copper mesh, analyze and characterize them with a scanning electron microscope, Fourier transform infrared spectrometer, elemental analyzer, etc. respectively.

[0050] The Magna IR 560 Fourier Transform Infrared Spectrometer produced by Nicolet Company of the United States was used for measurement, and the scanning range was 400 to 4000 cm -1 , scanning sp...

Embodiment 2

[0060] Step 1: Add 1.25% (relative to the amount of PCC added) squash gum into the oblique three mouths containing 90g of water, raise the temperature to 80°C, stir and disperse at 400rpm, and then add 10g of precipitated calcium carbonate;

[0061] Step 2: Add 0.5% (relative to the amount of PCC) bistriethanolamine diisopropyl titanate into the reactor, and stir for 75 minutes;

[0062] Step 3: collecting the reaction product by centrifugation and washing and drying it;

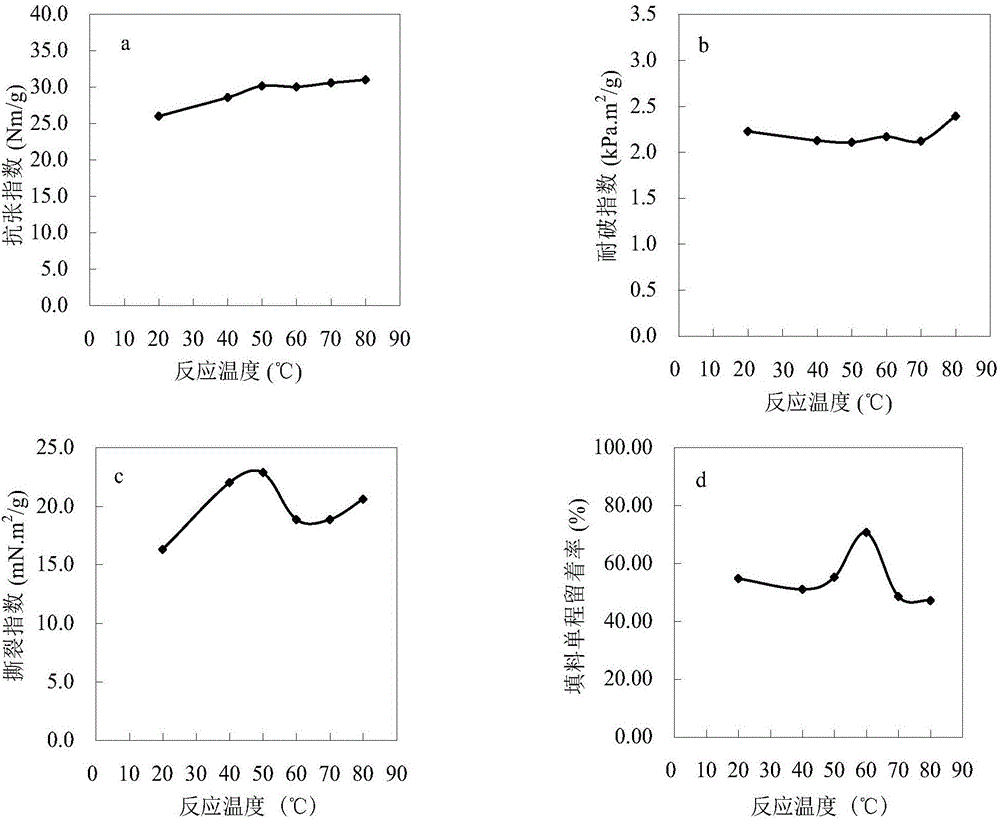

[0063] Step 4: Decompose the bleached kraft pulp soaked in water for more than 4 hours with a standard decomposer, and then use a beater to beat to 37°SR. After appropriate dilution, add modified precipitated calcium carbonate and precipitated calcium carbonate respectively. The filling amount is 20% (based on absolute dry pulp volume); refer to GB / T3703-1999 method, papermaking in sheet former; after pressing for 1 min at a pressure of 0.4 MPa in a hydraulic press, dry in a drier at 97°C for 5 min, and make...

Embodiment 3

[0067] Step 1: Add squash gum to the three oblique ports containing 90g of water, raise the temperature to 80°C, stir and disperse at 400rpm, then add 10g of precipitated calcium carbonate; the amount of squash gum is as follows Figure 6 Shown in a-6d, its consumption is respectively: 0.5%, 0.75%, 2%, 1.25%, 1.5%, 2.1%, 2.5%, 3.0%, 3.5%, 4% (relative to PCC adding amount).

[0068] Step 2: Add 10% (relative to the amount of PCC) bistriethanolamine diisopropyl titanate into the reactor, and stir for 60 minutes;

[0069] Step 3: collecting the reaction product by centrifugation and washing and drying it;

[0070] Step 4: Decompose the bleached kraft pulp soaked in water for more than 4 hours with a standard decomposer, then use a beater to beat to 37°SR, add modified precipitated calcium carbonate after appropriate dilution, and the filling amount is 20% (based on dry pulp volume);

[0071] Refer to the GB / T3703-1999 method, make paper in a sheet former; squeeze it for 1 minu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com