Displacement vector filling method based on energetic material approximate spherical filling maximization

A filling method, displacement vector technology, applied in the field of materials science, can solve problems such as lack

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

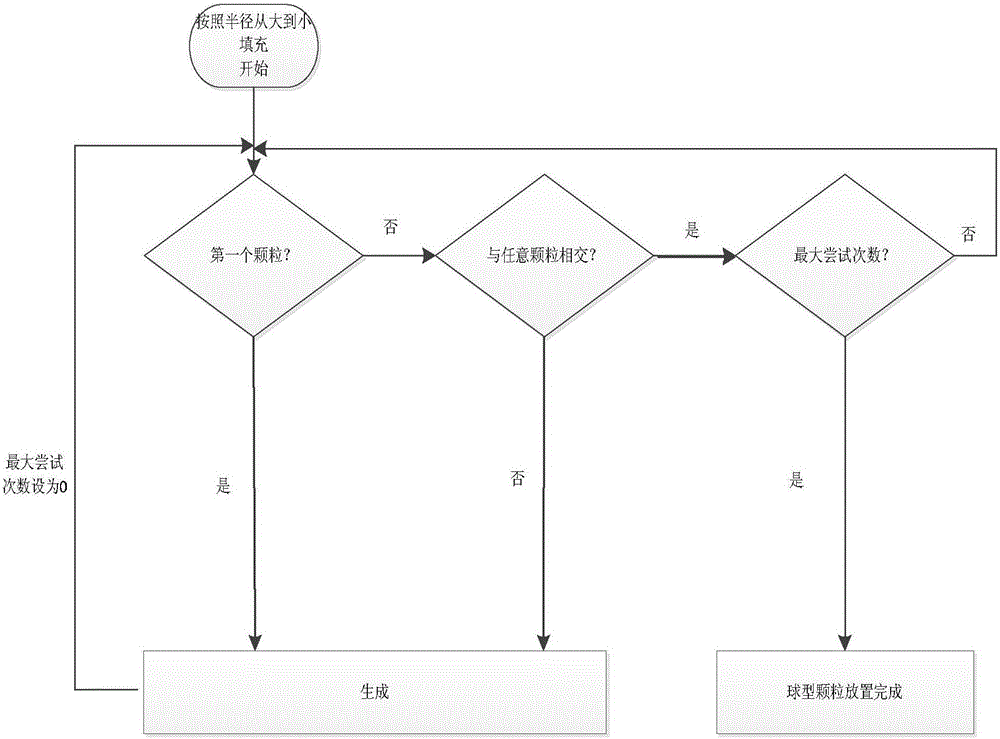

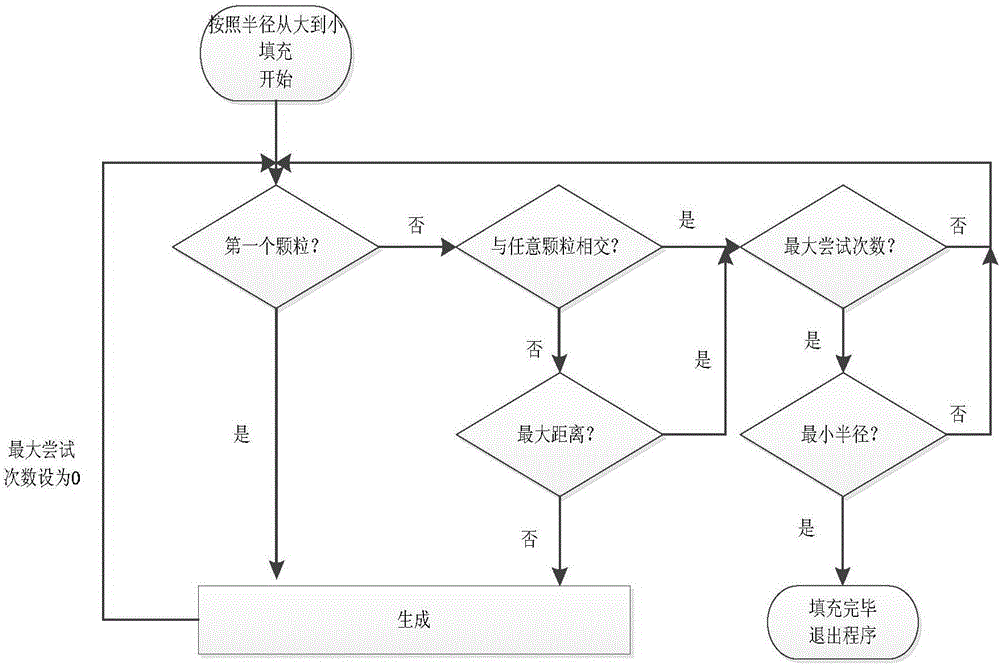

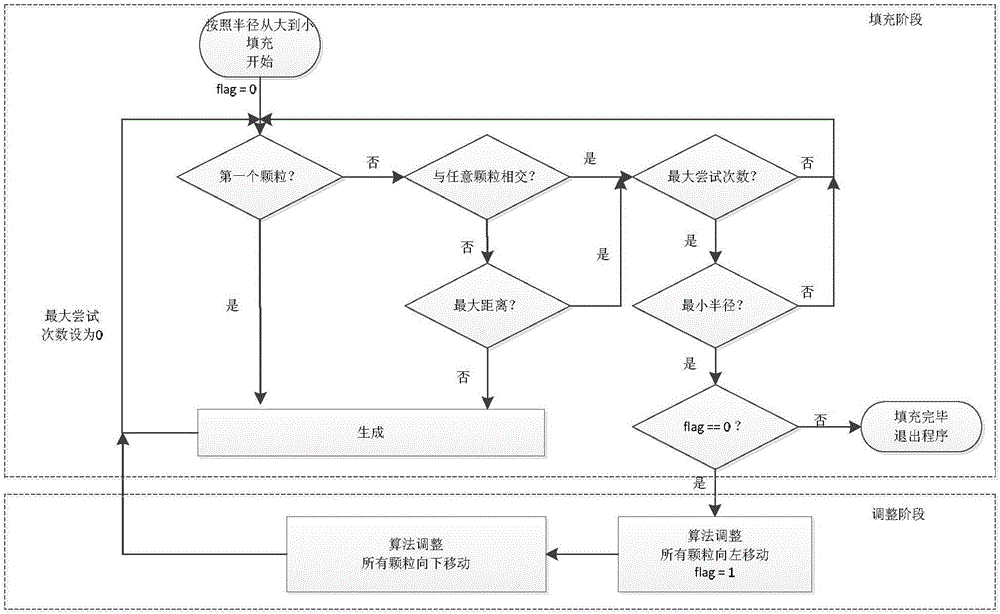

[0032] Below in conjunction with accompanying drawing, the present invention will be further described:

[0033] see figure 1 , image 3 For the analysis process of the present invention, as shown in the figure, the present invention provides an algorithm based on the approximate spherical filling maximization of energetic materials. The algorithm includes a filling stage and an adjustment stage. The steps are as follows:

[0034] Filling phase:

[0035] 1. Randomly put spherical particles into the compression chamber according to the radius from large to small, and set the radius as r 1 ,r 2 ,r 3 ......r n , set the maximum number of attempts to be 1 million times, the maximum gap to be d, and p to represent spherical particles;

[0036]2. Every time a spherical particle (except the first one) is placed, it will be compared with all previous particles one by one. If it intersects with any particle, this placement will be abandoned. If the distance to any particle is gre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com