Self-supporting housing of a dynamo-electric machine

An electric motor, self-supporting technology, applied in the direction of electric components, casings/covers/supports, electrical components, etc., can solve the problem of large effective parts, etc., and achieve simple methods and methods, optimized material application, and high rigidity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

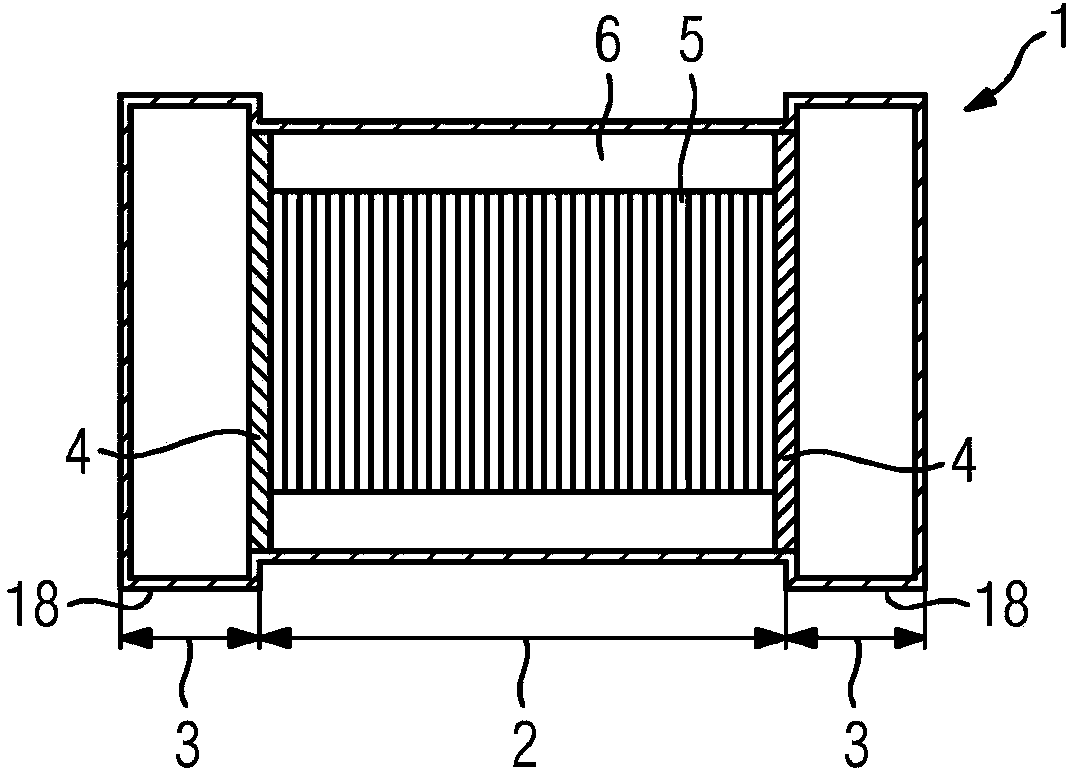

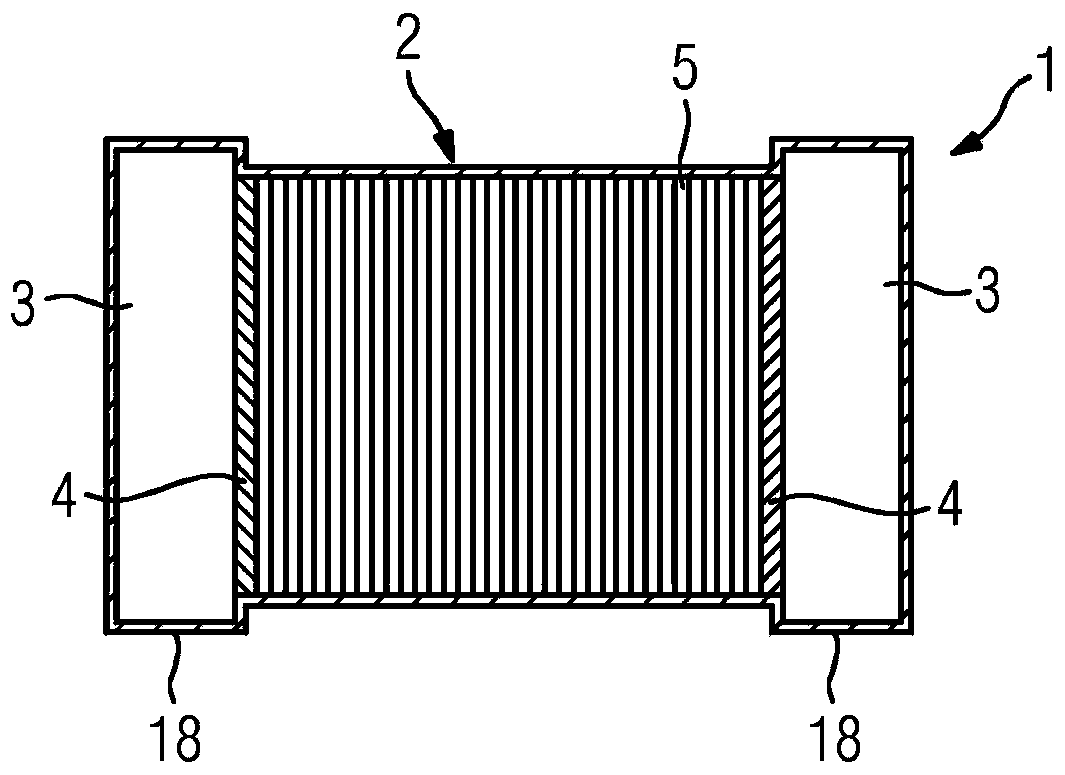

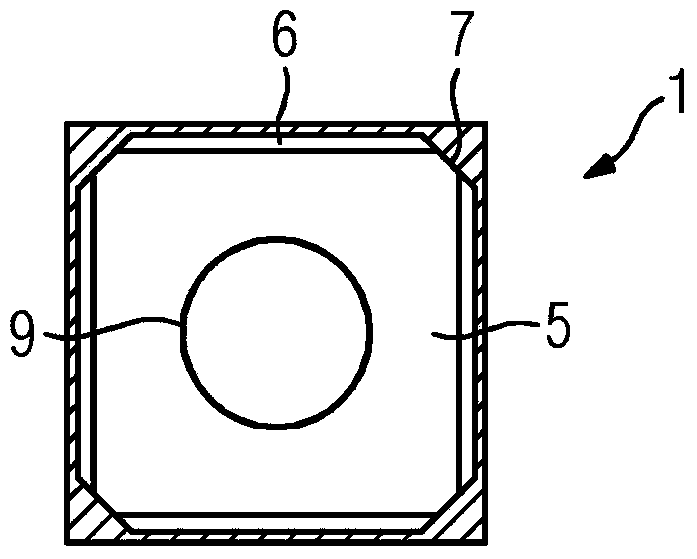

[0053] figure 1 Shows a principled longitudinal sectional view of a self-supporting housing 1 according to the invention of an electric motor 23 with a stator 22 whose plate pack 5 is layered by the shaft via a pressure plate 4 on the end face Laminated composition. With regard to the type of construction of the self-supporting shell 1 , shell parts or shell sections, reinforcements, profiles and cladding are connected to one another using different joining techniques (soldering, welding, gluing). In this case, the load-bearing function is assumed solely by this housing structure. Rigidity is achieved by a compact housing construction, by possibly hollow housing parts with as large a cross-section as possible, and thus by a high resistance moment. For example, in Figure 8 and Figure 23 Beads, recesses (Eindellung), etc. in the center increase rigidity.

[0054] In particular, the housing 1 must be able to absorb the moments that occur during operation, so that it also s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com