Method for manufacturing non-linear crystal gallium selenide component

A technology of nonlinear crystals and manufacturing methods, applied in chemical instruments and methods, crystal growth, single crystal growth, etc., can solve the problems of GaSe crystals such as low transmittance, easy deformation, splitting, etc., to reduce thermal lens effect, The effect of eliminating thermal stress and reducing the density of crystal defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0017] Specific embodiment one: the manufacturing method of the nonlinear crystal GaSe component of this embodiment is carried out according to the following steps:

[0018] 1. Use the volume ratio of HCl:HNO 3 =1: (3-3.5) mixed acid etches the surface of the GaSe crystal ingot for 1-2 minutes to remove impurities such as oxides on the crystal surface, then cleans and dries with ultra-pure water;

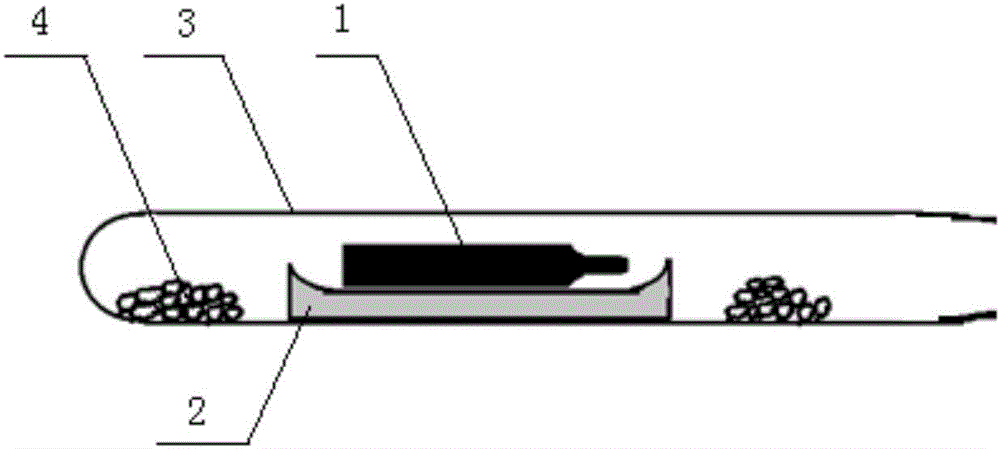

[0019] 2. Put the GaSe crystal ingot into a quartz boat or a boron nitride (PBN) boat, and then put the boat in the middle of the quartz tube; place GaSe polycrystalline powder at both ends of the boat, and the mass ratio of the crystal ingot to the polycrystalline powder is 10 :(1~2); or put GaSe polycrystalline powder at one end of the boat, and simple Se at the other end, the mass ratio of crystal ingot to polycrystalline powder is 10:(0.5~1), the mass ratio of crystal ingot to Se is 10: (0.05~0.1); Then vacuumize the quartz tube to 10-4~10-6Pa, seal the quartz tube with a hydro...

specific Embodiment approach 2

[0023] Embodiment 2: This embodiment is different from Embodiment 1 in that the drying temperature in step 1 is 50°C-60°C. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0024] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is that the quartz tube in step one is evacuated to 10 -4 ~10 -6 Pa. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com