Fluid-actuated diaphragm drive

A driving device and diaphragm technology, applied in the direction of fluid pressure actuation device, valve operation/release device, valve device, etc., can solve the problems of heavy raw material cost and large driving shell, and achieve rigid optimization and easy cleaning. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

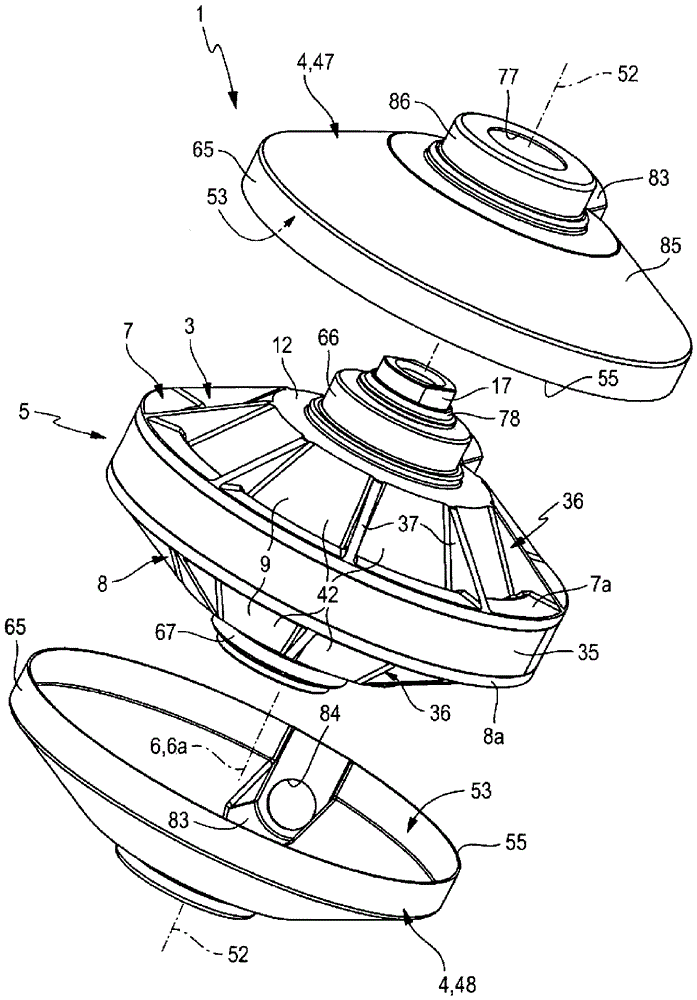

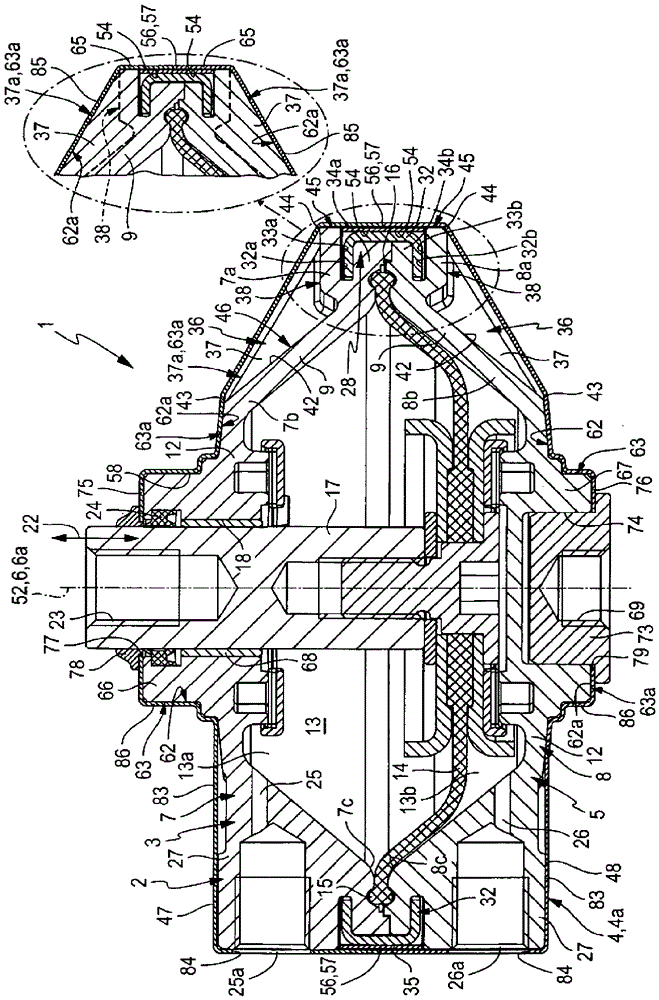

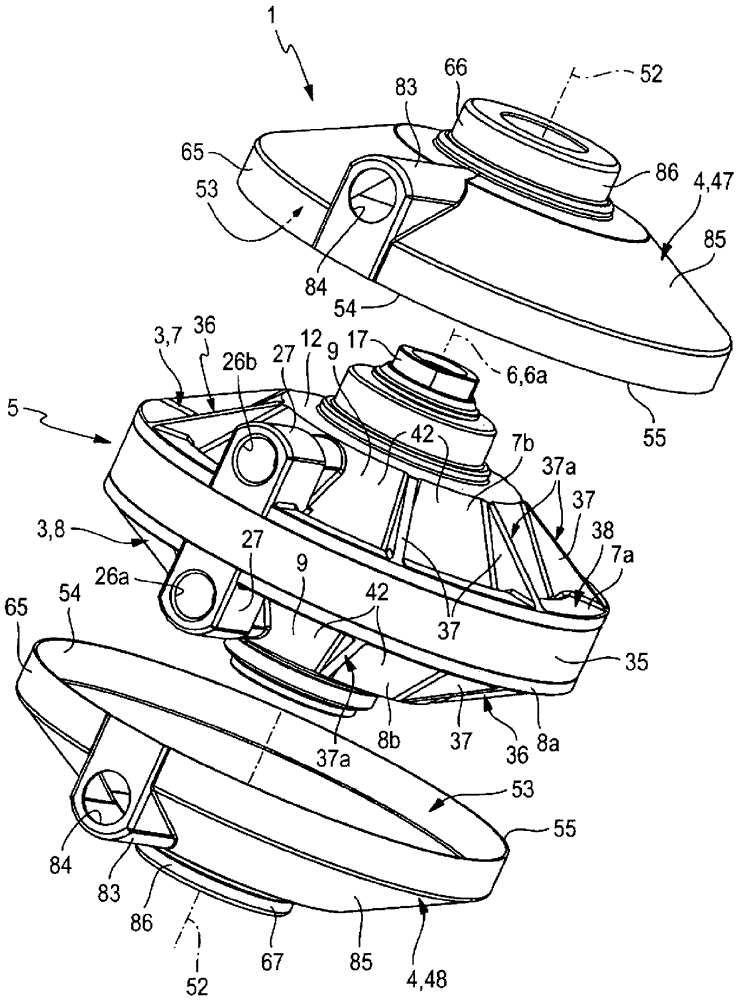

[0031] The diaphragm drive described in its entirety with the reference numeral 1 is of the fluid-actuated type and can be driven by a fluid force provided by a drive medium in a fluid state that can be supplied as required and that can be discharged . Such a drive medium is especially compressed air. However, the diaphragm drive 1 can also be driven by means of another gaseous drive medium or by means of a liquid drive medium.

[0032] The diaphragm drive 1 , which is the housing whose entirety is denoted by reference numeral 2 , has an advantageous hybrid construction with a mixture of plastic material and rust-resistant steel. These materials are distributed, and specifically on the one hand, as a drive housing 3 formed of plastic material and as an enveloping shell 4 of rust-resistant sheet steel surrounding said drive housing 3 . The casing has a protective and support function in order to optimize the use possibilities of the diaphragm drive 1 , which is theoretically ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com