Welding method for box

A welding method and box body technology, applied in welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of box integrity and poor carrying capacity, and achieve the effect of improving integrity and carrying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

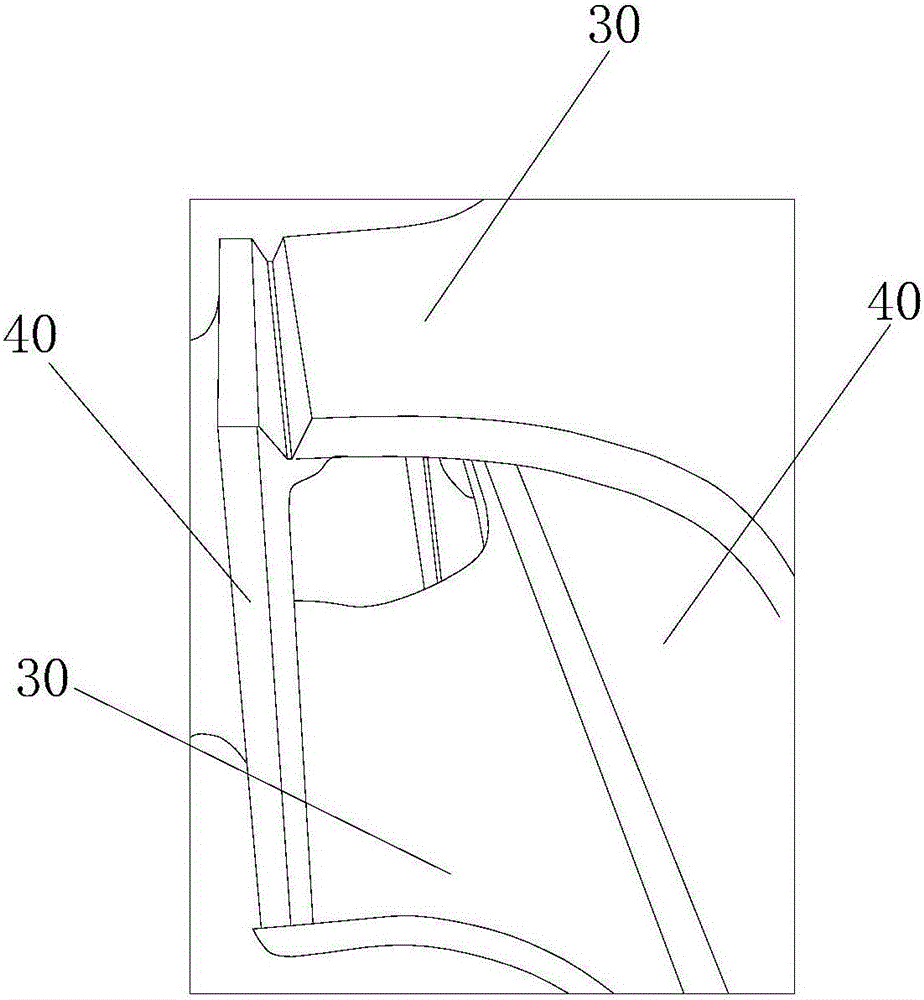

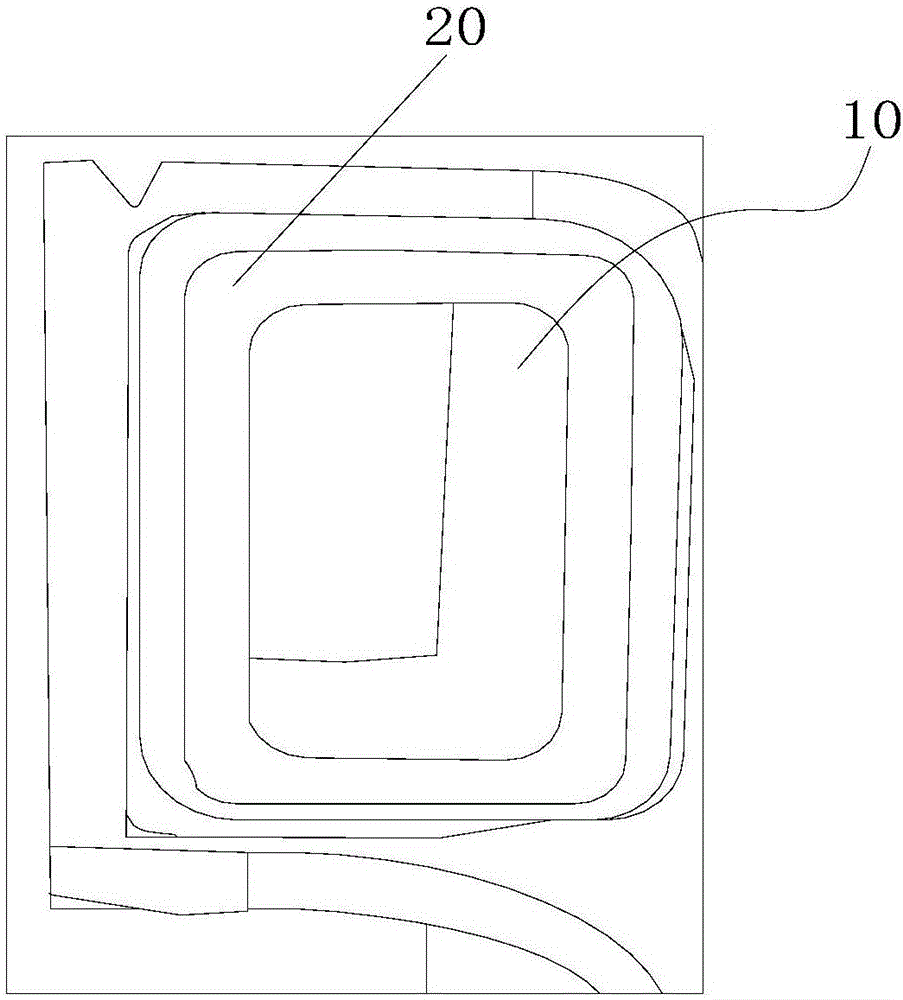

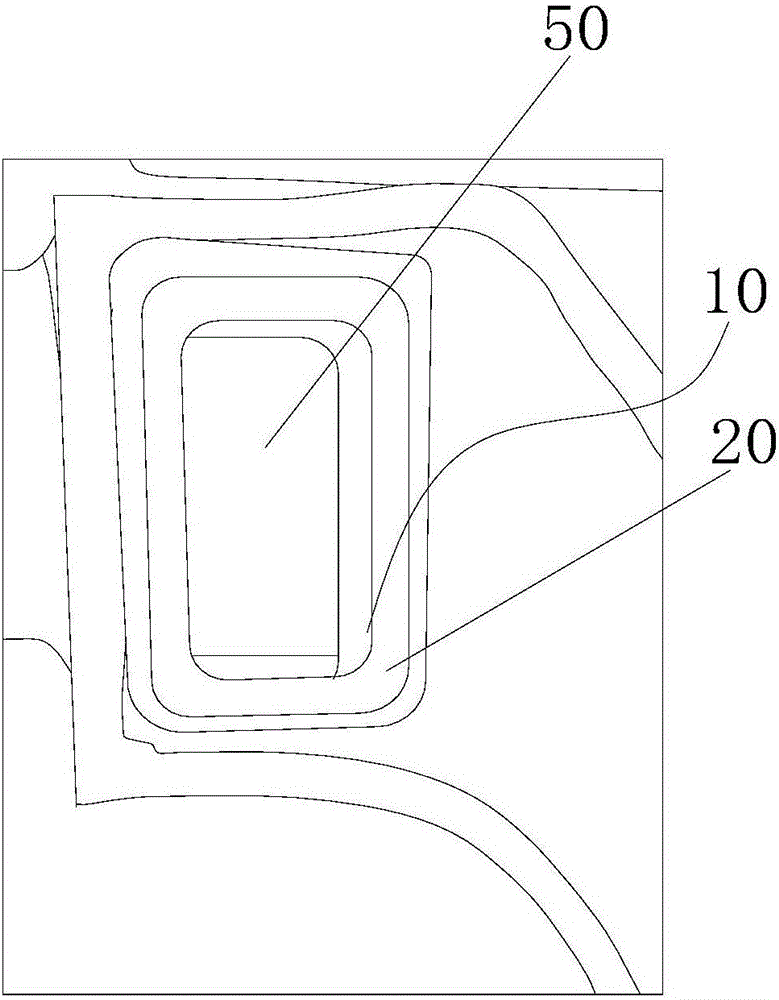

[0021] According to a specific embodiment of the present invention, a box body welding method is provided, wherein the box body is composed of a plurality of substrates, and the welding method includes: setting an escape portion 10 on at least one of the substrates; Welding is performed to form a base body with an opening, on which there is a base plate with a relief portion 10; and the rest of the base plate is welded to the opening of the base body through the escape portion 10 to form a box.

[0022] Applying this configuration method, when welding the box body, by providing the avoidance portion 10 on at least one substrate, after welding some of the plurality of substrates to form a base body with openings, the avoidance portion 10 can be passed Weld the remaining base plate to the opening in the base body, thus completing the welded connection to all welds inside the box.

[0023] Compared with the way in the prior art that multiple non-porous plates are spliced and as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com