Receiving net type winding machine

A technology of winding machine and winding mechanism, which is applied in the direction of electrical components, inductance/transformer/magnet manufacturing, circuits, etc. It can solve problems such as dropping and core damage, and achieve the effect of saving costs and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

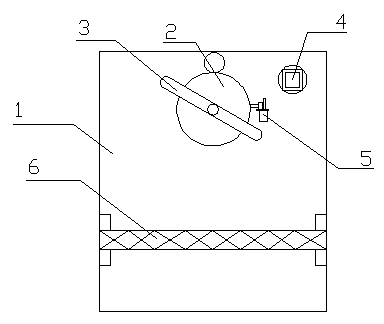

[0010] Such as figure 1 It is a schematic diagram of the structure of a ladle winder. A ladle winder includes a frame 1, a winding mechanism 2, an unloading mechanism 3, an introduction device 4, a shearing mechanism 5, and a winding mechanism 2. , The induction device 4 and the shearing mechanism 5 are fixed on the frame 1, the winding mechanism 2 is provided with the unloading mechanism 3, the bag net 6 is fixedly connected to the frame 1, and the bag net 6 is fixedly connected to the frame through the fixing frame 1 on.

[0011] When working, the iron core is introduced to the winding mechanism 2 by the introduction device 4, so that the winding mechanism 2 curls the iron core into shape, and then uses the shearing mechanism 5 to cut the iron core tape to complete the processing of an iron core, and finally the material is returned The mechanism 3 pulls the iron core out of the winding mechanism 2 and falls into the pocket net 6. The pocket net 6 can replace the hopper, avoid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com