Cleaner head

A technology for vacuum cleaners and vacuum cleaners, applied in the directions of vacuum cleaners, suction nozzles, cleaning equipment, etc., can solve the problems of high cost and increase the storage space of the head of the cleaner, and achieve the effect of high possibility, improved pickup performance, and good pickup performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] The embodiments of the present invention are described below by way of example only. These examples represent the best way to practice the invention currently known to the applicant, although they are not the only way to achieve this goal. This description explains the functions of the example and the sequence of steps to construct and run the example. However, the same or equivalent functions and sequences can be accomplished through different examples.

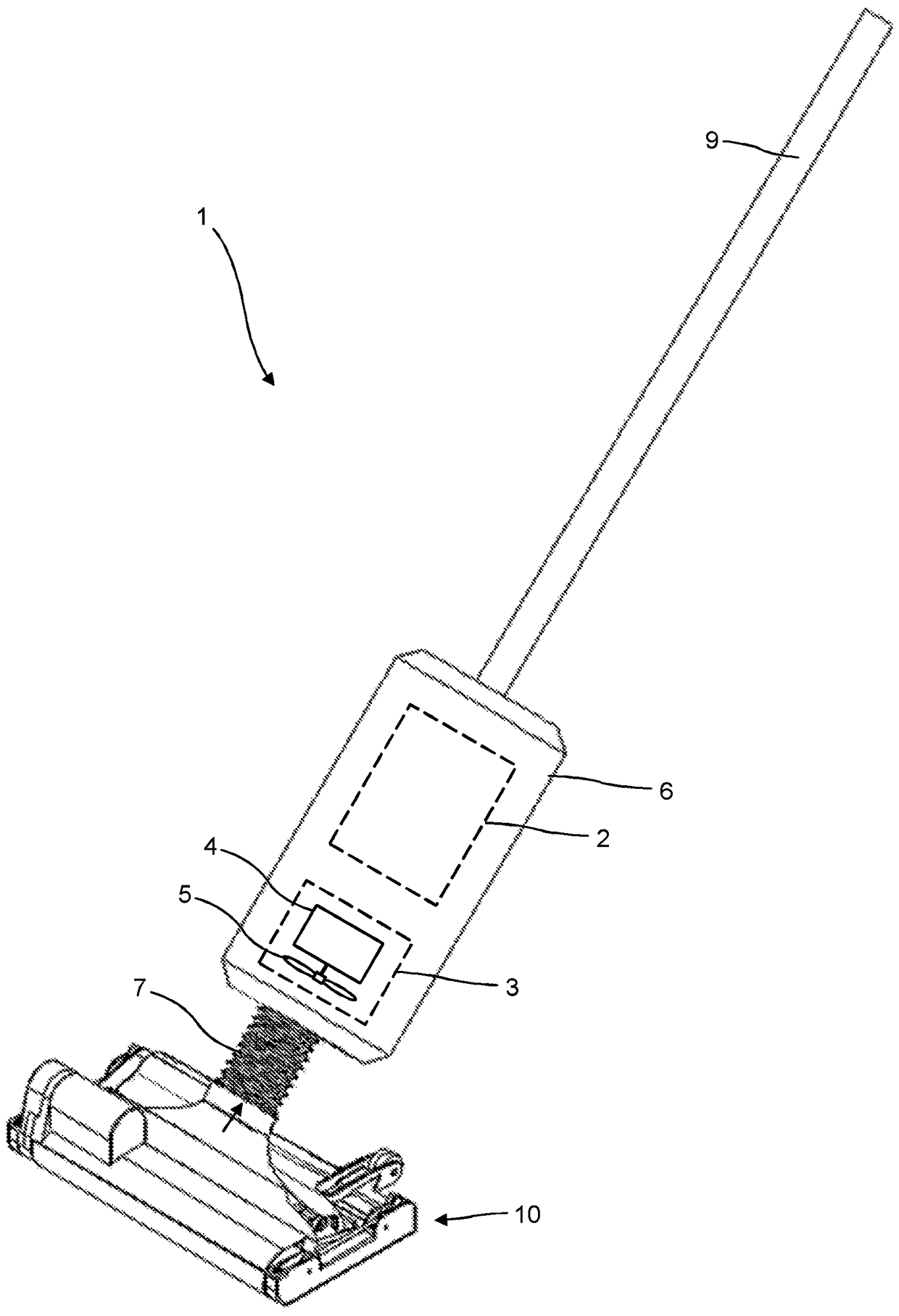

[0064] figure 1 A vacuum cleaner 1 is shown, comprising a cleaner head 10, a separation system 2, a suction source 3 and a tube 7 connected to the cleaner head 10. The separation system 2 and the suction source 3 can be installed in the housing 6. The vacuum cleaner 1 includes a handle 9 for pushing the cleaner head over the floor surface.

[0065] The tube 7 is fluidly connected to the cleaner head 10 and the separation system 2. The tube 7 is configured to transport dirty fluid (such as air) from the cleaner head 10 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com