Universal type high speed intelligent automatic screw fastening mechanism

A universal type, screw technology, used in metal processing, metal processing equipment, manufacturing tools, etc., to achieve the effect of improving work efficiency, small footprint, and simplified mechanism structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

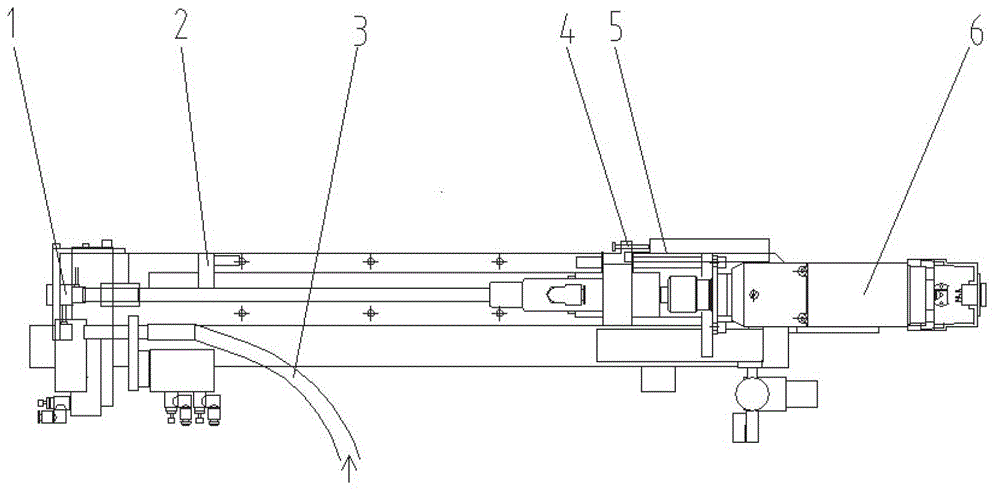

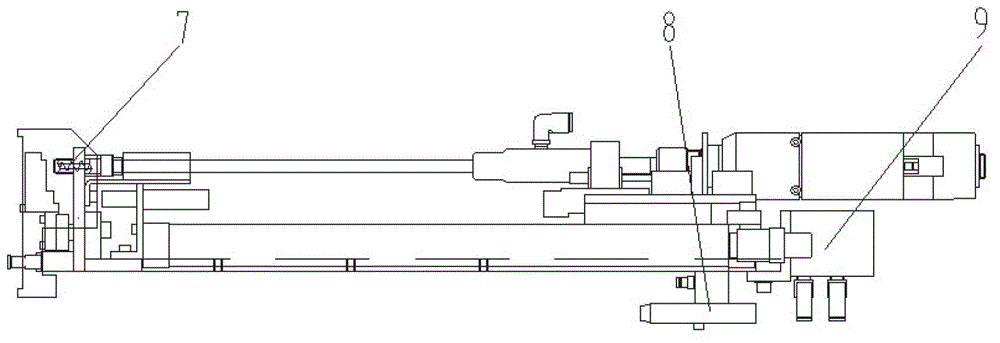

[0021] The universal high-speed intelligent automatic screw locking mechanism will be described in detail below in conjunction with the embodiments.

[0022] The screw is blown by the soft material tube 3 into the screw pushing device 1, and the screw pushing device 1 pushes it to an accurate position, and the screw cylinder 9 controls the vacuum suction pipe to move to the screw direction, and at the same time, the vacuum generator 8 acts to suck the screw, and the screwdriver drives the cylinder Bring the screwdriver head 7 to the designated position for installing the screw, the screwdriver 6 rotates and moves to the screw locking position under the drive of the cylinder, so as to realize the fastening and assembly of the screw.

[0023] When the equipment is working, the screw is blown to the screw pushing device by the matching screw supply mechanism through the soft material tube, and the screw-taking cylinder pushes the vacuum suction pipe to move towards it. At the same...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com