Winding machine with elastic protection function

A protection type, winding machine technology, used in coil manufacturing, electrical components, inductor/transformer/magnet manufacturing, etc., can solve problems such as easy damage to the iron core, and achieve the effect of saving costs and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

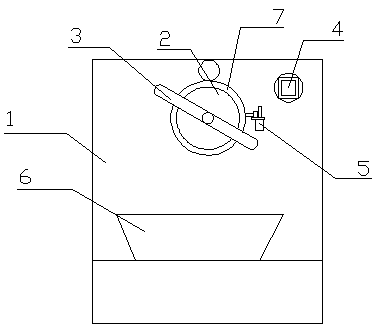

[0010] Such as figure 1 It is a structural schematic diagram of an elastic protective winding machine. A protective winding machine includes a frame 1, a winding mechanism 2, a material return mechanism 3, an introduction device 4, a shearing mechanism 5 and a hopper 6. The winding The mechanism 2, the introduction device 4 and the shearing mechanism 5 are fixed on the frame 1, the winding mechanism 2 is provided with a material return mechanism 3, the hopper 6 is fixedly connected to the frame 1, and the outer edge of the winding mechanism 2 is provided with a protective layer 7. The protective layer 7 is an elastic rubber layer.

[0011] During work, the iron core is introduced into the winding mechanism 2 by the introduction device 4, so that the winding mechanism 2 curls the iron core into shape, and the protective layer 7 on the winding mechanism 2 can utilize its elasticity to protect the iron core from being damaged during the curling process. It will be damaged due to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com