Cover easy to tear and manufacturing method thereof

A manufacturing method and technology of easy-to-tear caps, applied in the direction of caps, flexible coverings, bottle/container caps, etc., can solve the problems of sealing film damage, rupture, sealing film cracks, etc., so that it is not easy to break, guarantee normal use, Good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

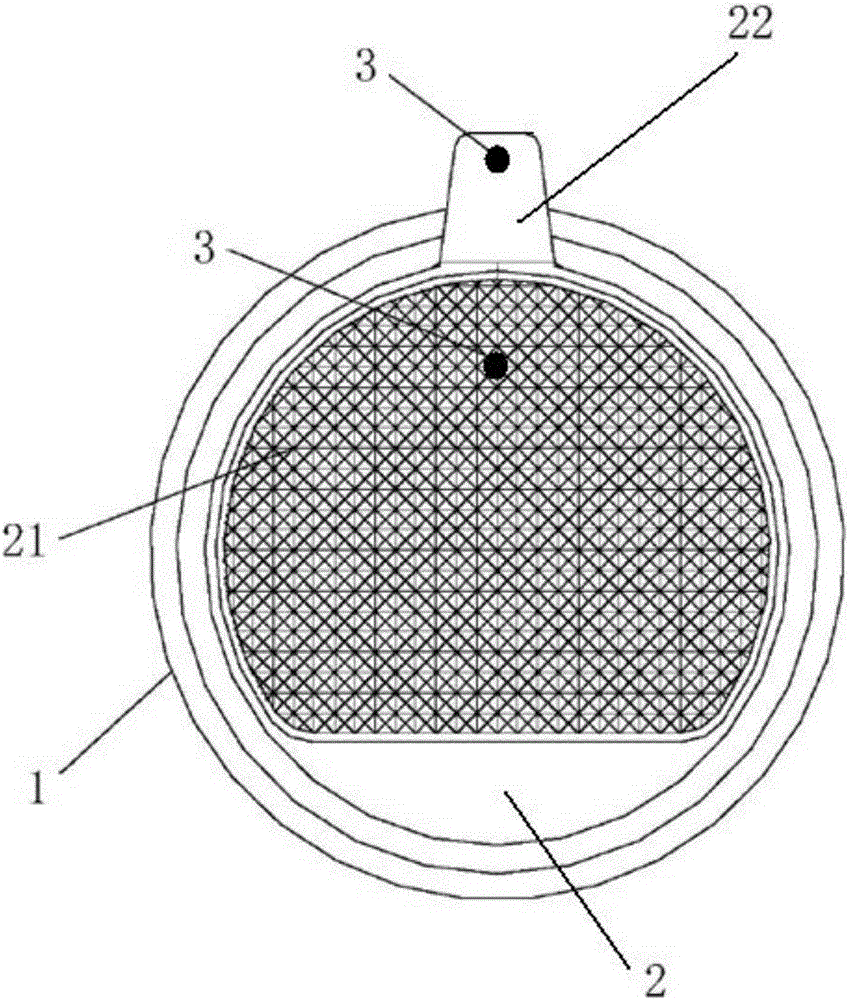

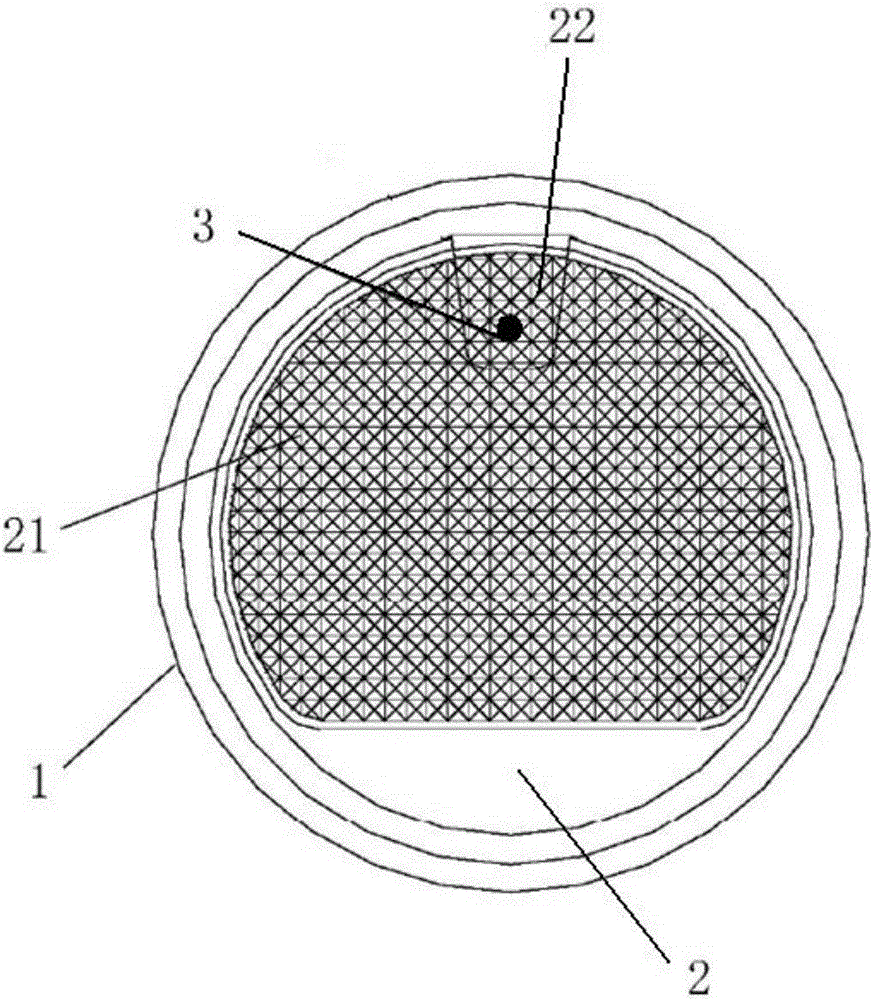

[0055] refer to figure 1 and figure 2 , an easy-tear cover of the present invention, comprising

[0056] The cover body 1 is provided with an extraction hole 11;

[0057] The parafilm 2 includes a parafilm body 21 and a pull-tab 22 arranged at the edge of the parafilm body 21. The seal cover of the parafilm body 21 is mounted on the extraction hole 11, and the pull-tab 22 can be folded under the action of an external force. onto the parafilm body 21;

[0058] It also includes a glue layer 3, the glue layer 3 is arranged on the pull tab 22 and / or the parafilm body 21, for connecting the pull tab 22 folded on the parafilm body 21 with the The parafilm body 21 is bonded. The specific form of the glue in the glue coating layer can be various, for example, it can be heat-sealing glue or hot-melt glue.

[0059] The easy-tearable lid of the present invention is applied to the lid to be installed on the tank body, so as to realize the sealing and opening of the tank body. Durin...

Embodiment 2

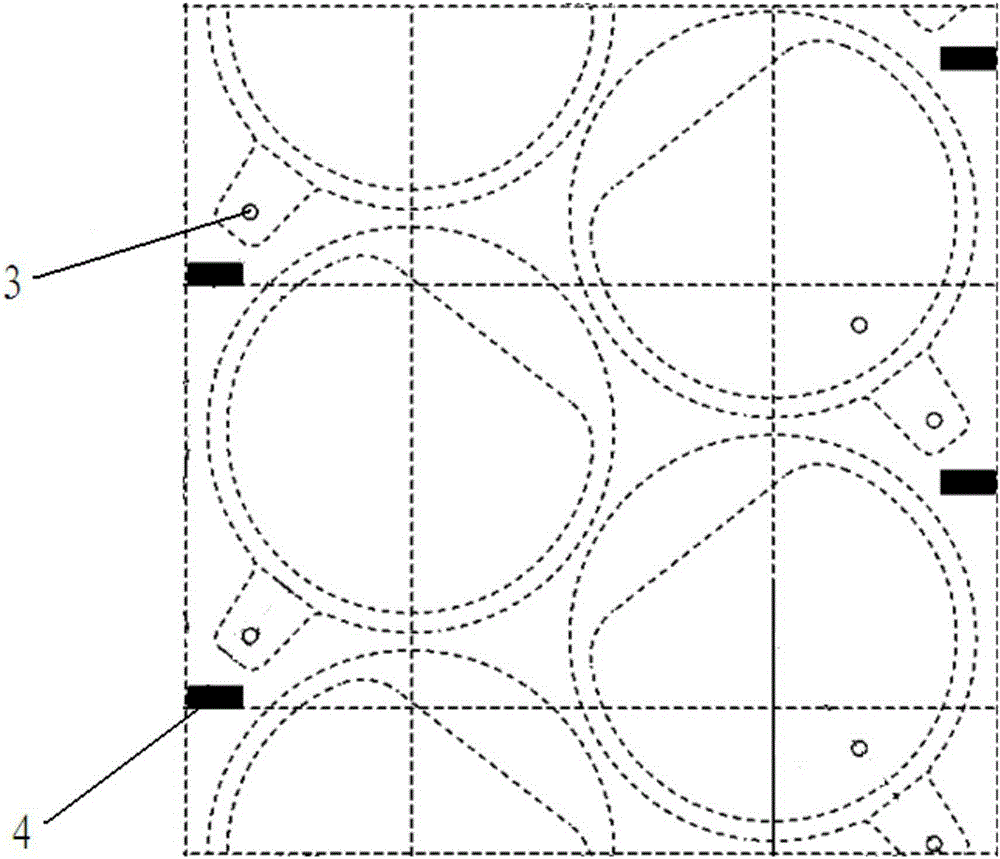

[0068] This embodiment provides a method for manufacturing an easy-tear cover, which includes the following steps:

[0069] S1: printing a cursor 4 on the outer surface of the aluminum foil;

[0070] S2: Determine the gluing area according to the position of the cursor 4, and form the gluing layer 3 in the gluing area;

[0071] S3: forming a varnish layer on the outer surface of the aluminum foil, the varnish layer does not cover the cursor 4; if the varnish layer is transparent, the varnish layer can also cover the cursor 4;

[0072] S4: forming a heat-sealing layer on the inner surface of the aluminum foil; the heat-sealing layer is formed by heat-sealing glue, and when the heat-sealing glue is used to form the heat-sealing layer, the heat-sealing glue is first coated on the inside of the aluminum foil On the surface, drying treatment is carried out to form a heat-sealing layer;

[0073] S5: Cut the aluminum foil into the shape of the required parafilm 2, the parafilm 2 in...

Embodiment 3

[0095] This embodiment provides a method for manufacturing an easy-tear cover, which includes the following steps:

[0096] S1: printing a cursor 4 on the outer surface of the aluminum foil;

[0097] S2: Determine the gluing area according to the position of the cursor 4, and form the gluing layer 3 in the gluing area;

[0098] S3: forming a varnish layer on the outer surface of the aluminum foil;

[0099] S4: Form a heat-sealing layer on the inner surface of the aluminum foil; the heat-sealing layer is formed by using a PE film, and when the heat-sealing layer is formed by using a PE film, first coat the inner surface of the aluminum foil Adhesive, then carry out drying treatment, then heat-compress the PE film on the side of the aluminum foil coated with the adhesive, and then put the aluminum foil compounded with the PE film in the curing chamber for curing to form a heat-sealing layer;

[0100] S5: Cut the aluminum foil into the shape of the required parafilm 2, the para...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com