Manufacturing method for low-cost monocrystalline silicon chips for photovoltaic cells

A cost-effective single-crystal, photovoltaic cell technology, applied in fine working devices, manufacturing tools, stone processing equipment, etc., can solve problems such as increasing production costs, consuming a large amount of electricity, increasing the consumption of carbon footprint of single-crystal silicon wafers, etc. Carbon footprint, effect of reducing overall electricity consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] A method for manufacturing a low-cost monocrystalline silicon wafer for photovoltaic cells provided in this embodiment includes

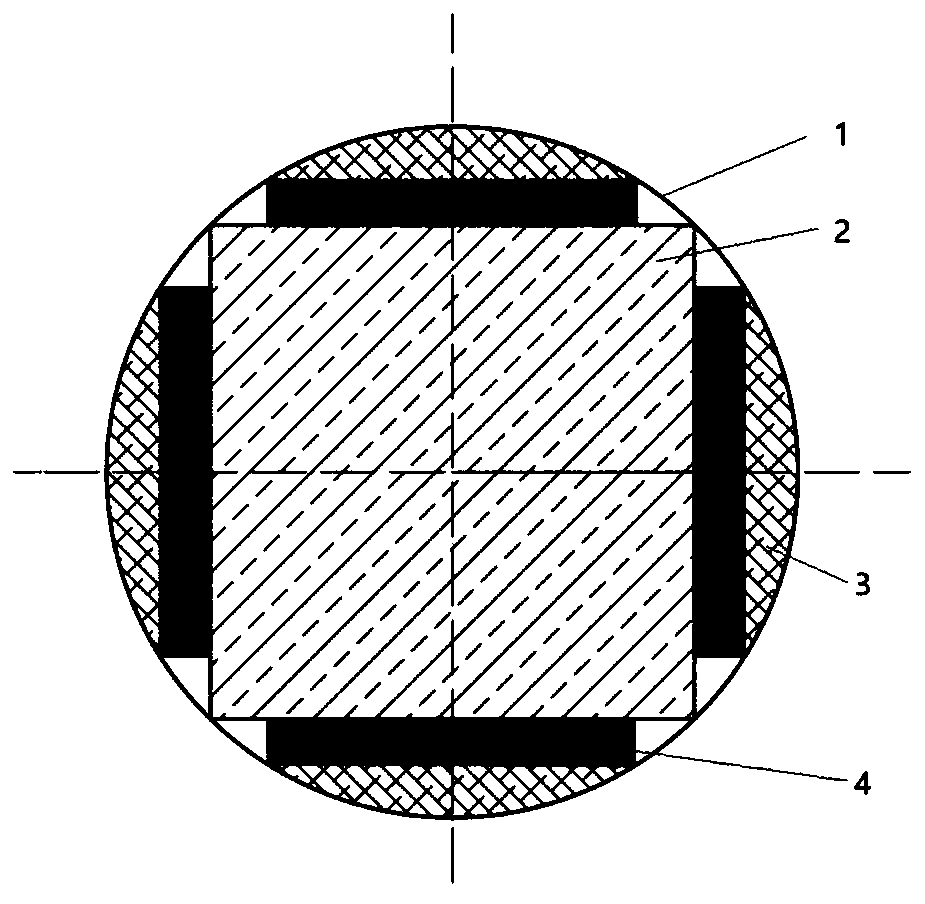

[0025] S1. Cut off a single wafer rod 1 with a length of 650 mm and a diameter of 300 mm, such as figure 1 As shown, the square is divided into two steps: first, set the square line according to the spacing of 210+20+20mm, cut the 300mm round bar 1 into a quasi-square bar 2 with a side length of 250mm, and produce 4 pieces of round arches Material 3; then this quasi-square bar 2 is cut into a square bar with a side length of 210mm, and four monocrystalline slabs 4 with a thickness of 20mm and a length of 650mm are produced;

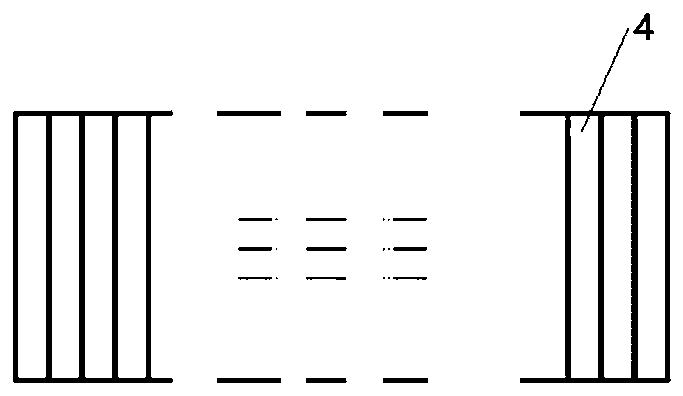

[0026] S2. Bonding a certain number of single crystal slabs 4 together with hydrosol, and using a polycrystalline squarer to square the single crystal slabs 4 into a silicon block with a size of 158mmx158mm and a thickness of 20mm;

[0027] S3. Bond the silicon blocks together with hydrosol to form a composite square ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com