Carbon material for negative electrode of lithium ion battery and preparation method thereof, negative electrode of lithium ion battery, and lithium ion battery

A lithium-ion battery and carbon material technology, applied in battery electrodes, carbon preparation/purification, secondary batteries, etc., can solve the problems of not fully exploiting the utilization value of coal direct liquefaction residue, achieve excellent rate performance and improve rate performance , the effect of good cycle stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

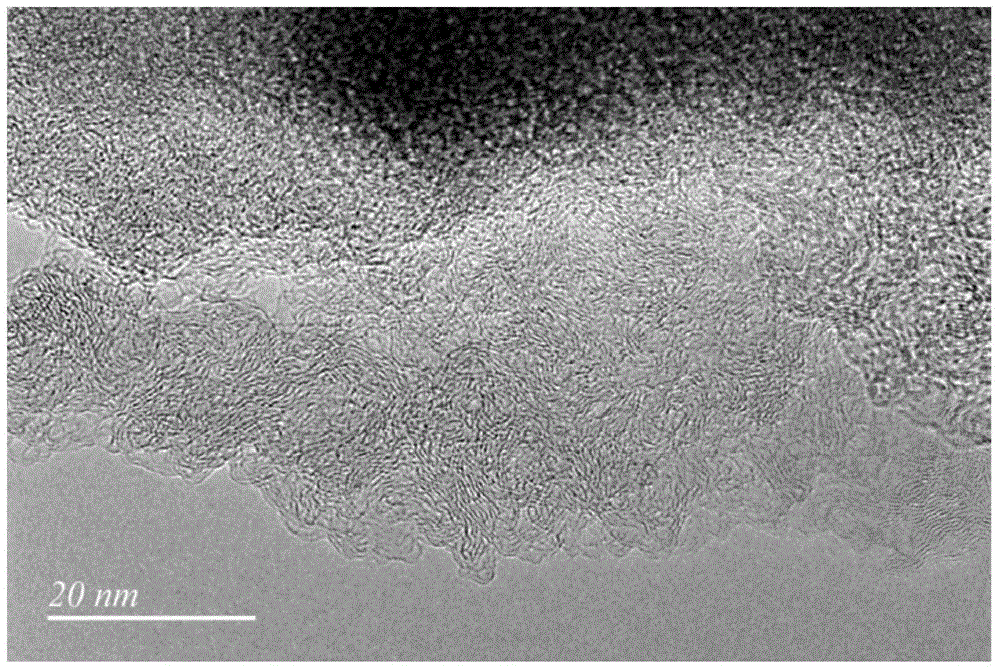

[0017] The invention provides a method for preparing a carbon material used for the negative electrode of a lithium ion battery, the method comprising: (1) thermally polymerizing coal direct liquefaction residue and / or coal tar pitch to obtain a thermally polymerized product; (2) Stabilizing the thermal polymerization product to obtain a stabilized product; (3) pre-calcining the stabilized product and ball milling the calcined product to obtain a carbide; (4) carbonizing the carbide, obtain a carbon material; wherein, before performing the pre-calcination in step (3), the stabilized product is mixed with a hard carbon precursor, or the stabilized product is mixed with an organic solution of the hard carbon precursor and Remove the organic solvent; and / or, before carrying out the carbonization in step (4), the substance to be carbide is mixed with the hard carbon precursor, or the stabilized product is mixed with the organic solution of the hard carbon precursor And remove the ...

Embodiment 1

[0050] This example is used to illustrate the preparation method of the carbon material used for the negative electrode of the lithium ion battery provided by the present invention and the negative electrode of the lithium ion battery.

[0051] 1) Purify the residue of direct coal liquefaction (containing 20% by weight of ash, produced by direct coal liquefaction of Shenhua Group, and the rest of the examples are the same) (to obtain coal liquefaction pitch, containing 91.19% by weight of carbon, 5.65% by weight of hydrogen, and an average molecular weight of 500, the softening point is 150°C, the ash content is less than 200ppm, and the rest of the examples are the same), after being crushed (the particle size is <5mm), put it into the polymerization reactor for thermal polymerization, the thermal polymerization temperature is 400°C, and the time is 8h to obtain thermal polymerization product;

[0052] Crush the thermal polymerization product, grind it finely in an agate mo...

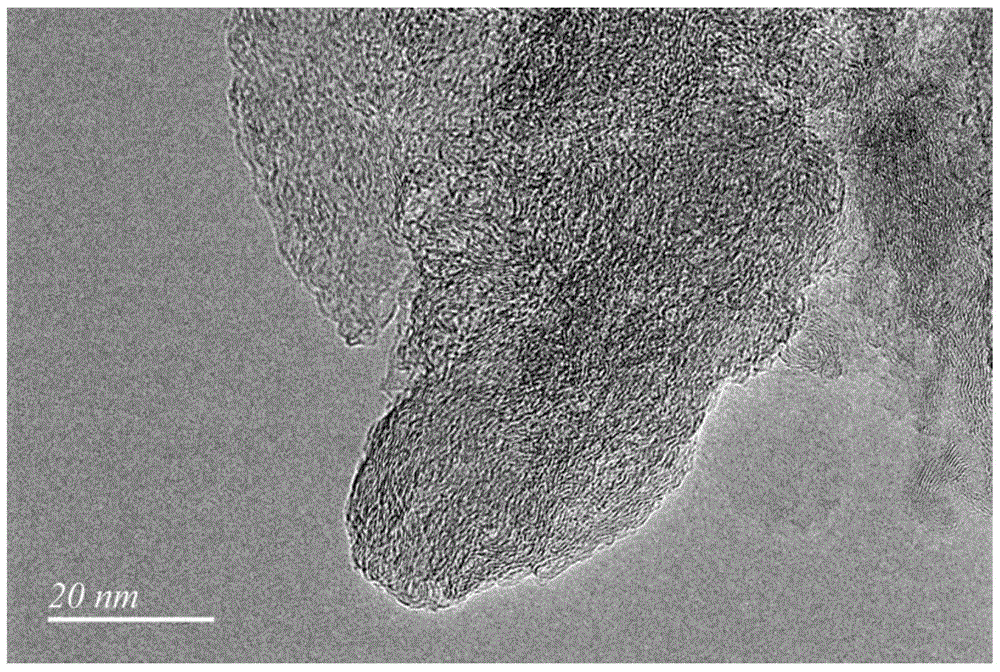

Embodiment 2

[0060] This example is used to illustrate the preparation method of the carbon material used for the negative electrode of the lithium ion battery provided by the present invention and the negative electrode of the lithium ion battery.

[0061] 1) After the coal tar pitch is crushed (with a particle size of <5 mm), it is put into a polymerization reactor for thermal polymerization. The thermal polymerization temperature is 390° C. and the time is 9 hours to obtain a thermal polymerization product;

[0062] Break the thermal polymerization product, grind it in an agate mortar, and sieve it with a 0.5mm sieve to obtain a thermal polymerization product below 0.5mm, weigh 50g and spread it on a tray, place it in a stabilizing furnace, and pass it into Air, adjust the flow rate to 4m 3 / h, after heating to 240°C, keep the temperature for 10h to obtain a stabilized product;

[0063] 10g of the stabilized product was pre-calcined at 800°C for 3 hours, and the pre-calcined product wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com