Binary and ternary transition metal hydrides as well as preparation method and application thereof

A transition metal and hydride technology, applied in metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, physical/chemical process catalysts, etc., can solve problems such as low conductivity of phosphides and poor catalyst stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] (1) Weigh 10 g of cobalt nitrate and 10 g of nickel nitrate, then stir and mix with 40 g of polyethylene glycol, and stir at 60° C. for 48 h; after stirring, add dropwise dilute nitric acid with a mass ratio of 10% to adjust the pH of the solution to 2;

[0025] (2) Put the mixed solution into a hydrothermal reaction kettle, and conduct a hydrothermal reaction at 200°C for 48 hours;

[0026] (3) After the hydrothermal reaction is completed, suction filter and wash the reactant with ultrapure water and ethanol to neutrality, and fully dry at 60°C;

[0027] (4) calcining the dry matter at high temperature for 2 hours to obtain a double metal oxide product;

[0028] (5) The product is loaded into a high-temperature and high-pressure reactor, 150° C., 3 MPa hydrogen pressure, and heated for 2 hours to obtain H 0.3 co 0.5 Ni 0.5 o 3 .

Embodiment 2

[0030] 1.H 0.3 Fe 0.33 co 0.33 Ni 0.33 o 3 preparation of

[0031] (1) Weigh 10g of cobalt nitrate, 10g of nickel nitrate and 13.2g of iron nitrate, then stir and mix with polyethylene glycol, and stir at 60°C for 48h; after stirring, add dropwise dilute nitric acid with a mass ratio of 10% to adjust the pH of the solution to 2;

[0032] (2) Put the mixed solution into a hydrothermal reaction kettle, and conduct a hydrothermal reaction at 200°C for 48 hours;

[0033] (3) After the hydrothermal reaction is completed, suction filter and wash the reactant with ultrapure water and ethanol to neutrality, and fully dry at 60°C;

[0034] (4) calcining the dry matter at high temperature for 2 hours to obtain a trimetallic oxide product;

[0035] (5) The product is loaded into a high-temperature and high-pressure reactor, 150° C., 3 MPa hydrogen pressure, and heated for 2 hours to obtain H 0.3 Fe 0.33 co 0.33 Ni 0.33 o 3 .

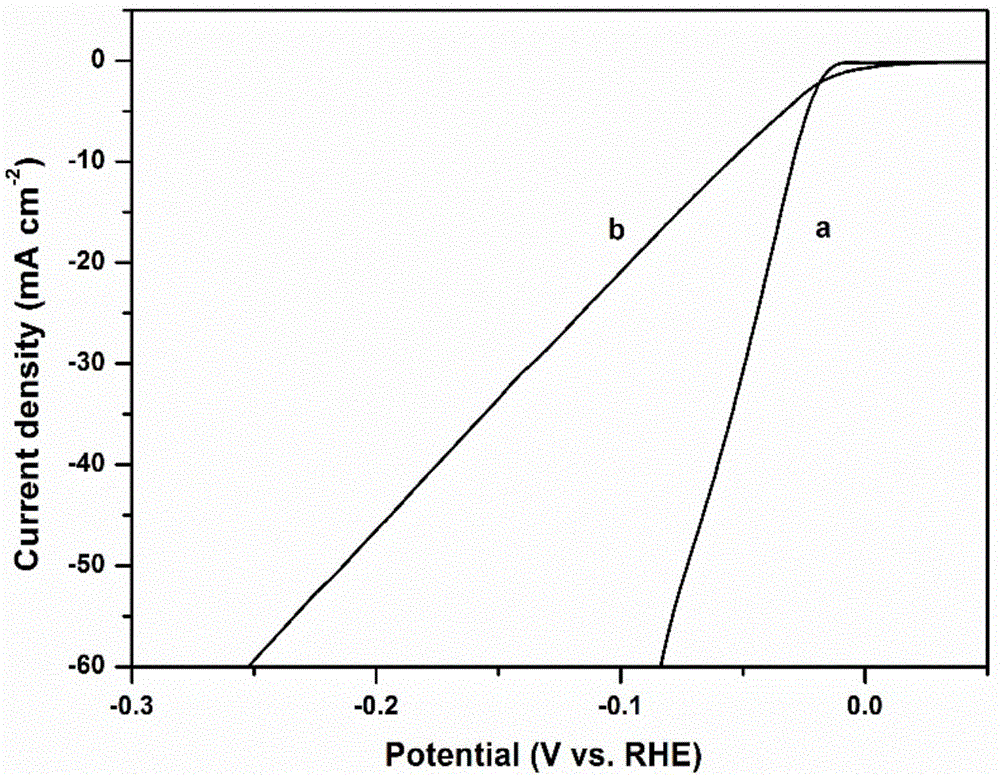

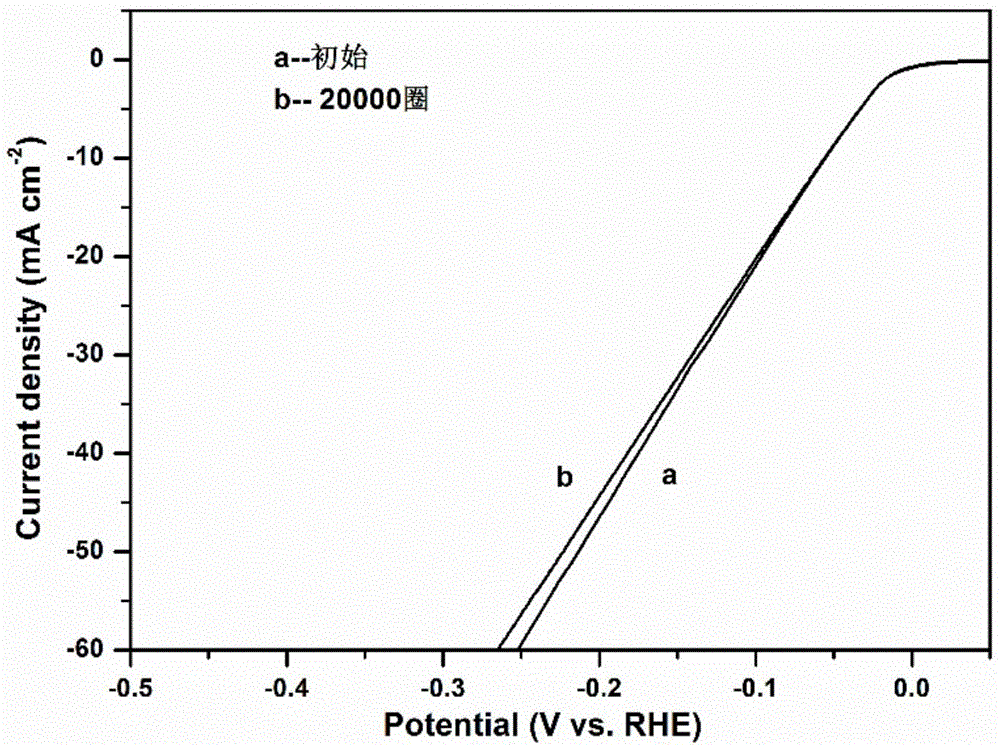

[0036] 2. H 0.3 Fe 0.33 co 0.33 Ni 0.33 o 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com