A kind of preparation method and application of efficient and stable bifunctional catalyst

A bifunctional catalyst and catalyst technology, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problems of rare reports on bifunctional catalysts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] (1) Weigh 30g of manganese nitrate and 10g of nickel nitrate, then stir and mix with 40g of polyethylene glycol, and stir at 60°C for 48h; after stirring, add dilute nitric acid with a mass ratio of 10% dropwise to adjust the pH of the solution to 2;

[0023] (2) Load the mixed solution into a hydrothermal reaction kettle, and conduct hydrothermal reaction at 200°C for 48h;

[0024] (3) the hydrothermal reaction finishes, suction filtration and wash the reactant to neutrality with ultrapure water and ethanol, and fully dry at 60°C;

[0025] (4) calcining the dried product at high temperature for 2h to obtain a bimetallic oxide product;

[0026] (5) put the product into the high temperature and high pressure reaction kettle, 150 ℃, 3MPa hydrogen pressure, heating reaction for 2h to obtain H 0.3 Mn 0.66 Ni 0.34 O 3 .

[0027] (6) 10g H 0.3 Mn 0.66 Ni 0.34 O 3 Disperse into 50mL of ethylene glycol / water solution, add 1.1mL of chloroplatinic acid solution 1g / mL dro...

Embodiment 2

[0029] (1) Weigh 10g of manganese nitrate, 6.6g of nickel nitrate and 12.7g of chromium nitrate, then stir and mix with polyethylene glycol, and stir at 60°C for 48h; after stirring, add dilute nitric acid with a mass ratio of 10% dropwise to adjust the pH of the solution to 2;

[0030] (2) Load the mixed solution into a hydrothermal reaction kettle, and conduct hydrothermal reaction at 200°C for 48h;

[0031] (3) the hydrothermal reaction finishes, suction filtration and wash the reactant to neutrality with ultrapure water and ethanol, and fully dry at 60°C;

[0032] (4) calcining the dried product at high temperature for 2h to obtain a trimetallic oxide product;

[0033] (5) put the product into the high temperature and high pressure reaction kettle, 150 ℃, 3MPa hydrogen pressure, heating reaction for 4h to obtain H 0.5 Mn 0.2 Ni 0.2 Cr 0.6 O 3 .

[0034] (6) 10g H 0.5 Mn 0.2 Ni 0.2 Cr 0.6 O 3 Disperse into 50mL of ethylene glycol / water solution, add dropwise 0.42...

Embodiment 3

[0036] 1. Pt / H 0.3 Mn 0.66 Ni 0.34 O 3 Preparation method of catalyst solution

[0037] Weigh 2.0mg Pt / H 0.3 Mn 0.66 Ni 0.34 O 3 The catalyst (hereinafter referred to as the catalyst) was dispersed in 1 mL of absolute ethanol, 11.2 μL of 5.0 wt% Nafion solution was added, and sonicated for 1 h to make the catalyst dispersed uniformly.

[0038] 2. Electrode spraying method

[0039] The treated glassy carbon electrode is fixed, and the ultrasonic catalyst solution is evenly added dropwise to the glassy carbon electrode to make it evenly distributed in the effective area of the glassy carbon electrode. For follow-up testing.

[0040] 3. Activation of the catalyst

[0041] Using a three-electrode system, the working electrode is the prepared carbon paper electrode; the counter electrode is a carbon rod; the reference electrode is a saturated calomel electrode; the electrolyte is 0.5mol / L H 2 SO 4 solution;

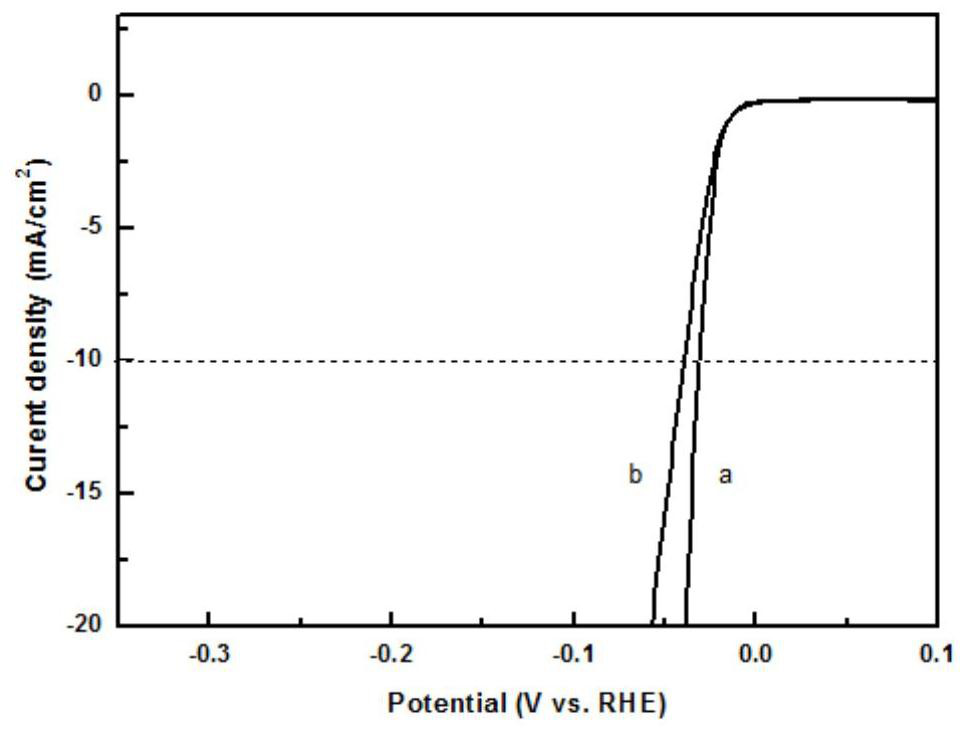

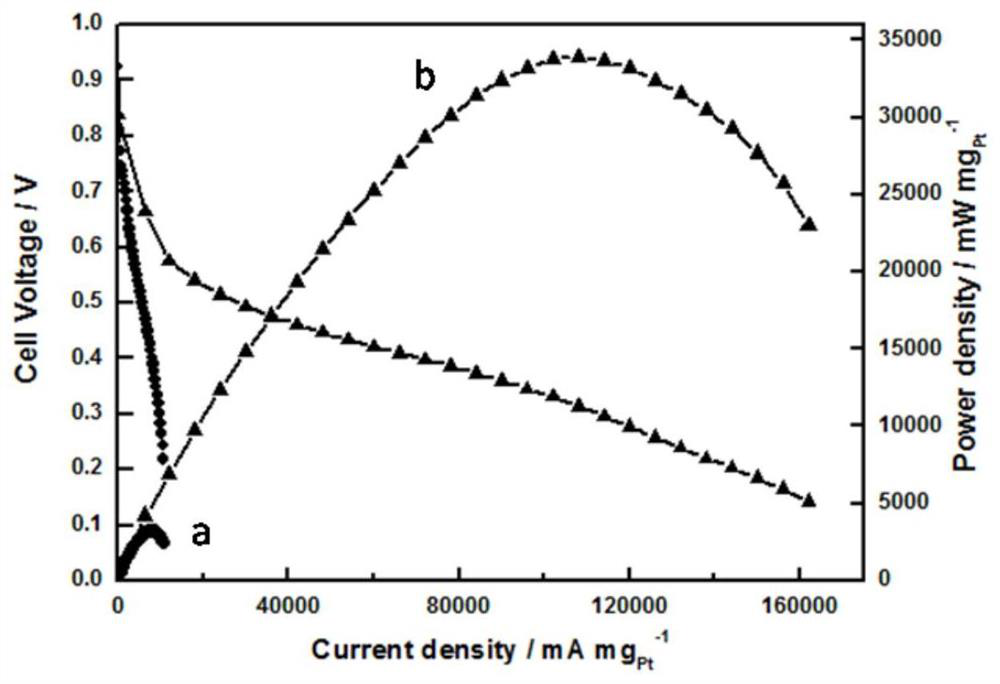

[0042] CV activation: using Gamry electrochemical workstat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com