Combined production device of hydrocarbon production through methanol dehydration and hydrogen and carbon dioxide production through methanol reforming

A methanol dehydration and carbon dioxide technology, applied in hydrogen, inorganic chemistry, carbon compounds, etc., can solve the problems of small-scale, unsuitable, and increased cost of hydrogen production by methanol reforming, and achieve hydrogen production cost reduction, thermal efficiency improvement, and large-scale The effect of efficient hydrogen production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

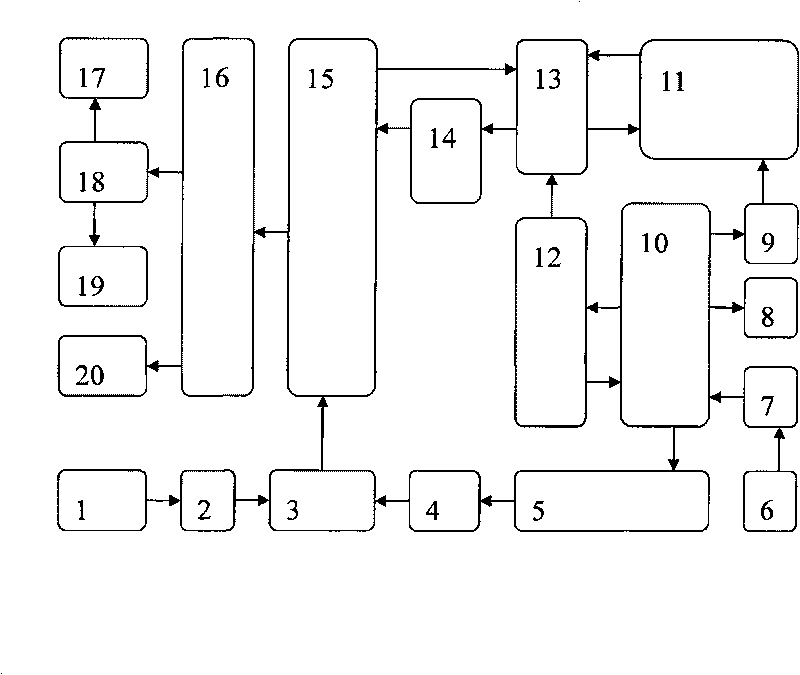

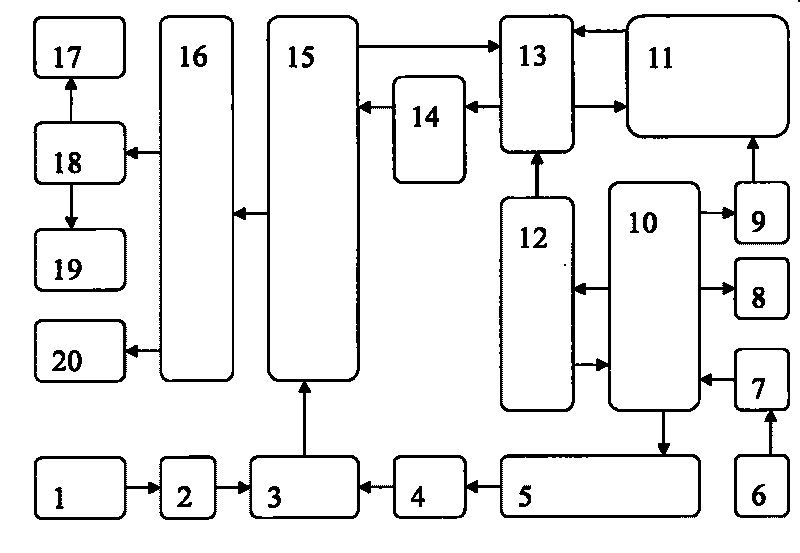

Image

Examples

Embodiment 1

[0009] Example 1: The dehydration hydrocarbon production system produces 10,000 tons of gasoline and liquefied gas per year, and consumes 25,000 tons of methanol. It can be equipped with a reforming system with an annual consumption of 25,000 tons of methanol to produce 34,000 tons of food-grade carbon dioxide, and the rest is hydrogen, more than 5,000 tons, for the production of thermal power and other purposes. It is suitable for building in small towns or supporting beverage and food enterprises.

Embodiment 2

[0010] Example 2: The dehydration hydrocarbon production system produces 100,000 tons of clean gasoline and liquefied gas annually, and consumes 250,000 tons of methanol. It can be equipped with a reforming system with an annual consumption of 250,000 tons of methanol to produce 340,000 tons of carbon dioxide, some of which are used to produce food-grade carbon dioxide and other carbon dioxide products of various specifications, and some can be transported back to the methanol plant for recycling methanol production. More than 50,000 tons of hydrogen can be used to produce thermoelectricity, and can also be refined for other purposes. It is suitable for supporting services for central cities and development zones.

[0011]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com