A kind of aluminum alloy/borohydride system for hydrogen production and preparation method thereof

A borohydride and aluminum alloy technology, applied in the field of hydrogen production, can solve the problems of increasing the cost of hydrogen production or strong corrosion of the system, and achieve the effects of low corrosion, good hydrolysis performance and low hydrogen production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] An aluminum alloy / borohydride system for hydrogen production prepared by a combination of ball milling and tableting. Under the protection of argon, the same component of the system was weighed and mixed by different methods to prepare the aluminum alloy / borohydride system.

[0030] System composition 1: Al, 30wt%; NaBH 4 , 50wt%; Li, 5wt%; CoCl 2 , 15wt%;

[0031] Method 1: Al, Li and CoCl 2 Mixing ball milling for 500min, rotating speed 400r / min, ball-to-material ratio 30:1; then mix with NaBH 4 Aluminum alloy / borohydride system made by mixed pressing;

[0032] Method 2: All system components are mixed and ball milled for 500 minutes at a speed of 400 r / min, with a ball-to-material ratio of 30:1; and then pressed into tablets to form an aluminum alloy / borohydride system.

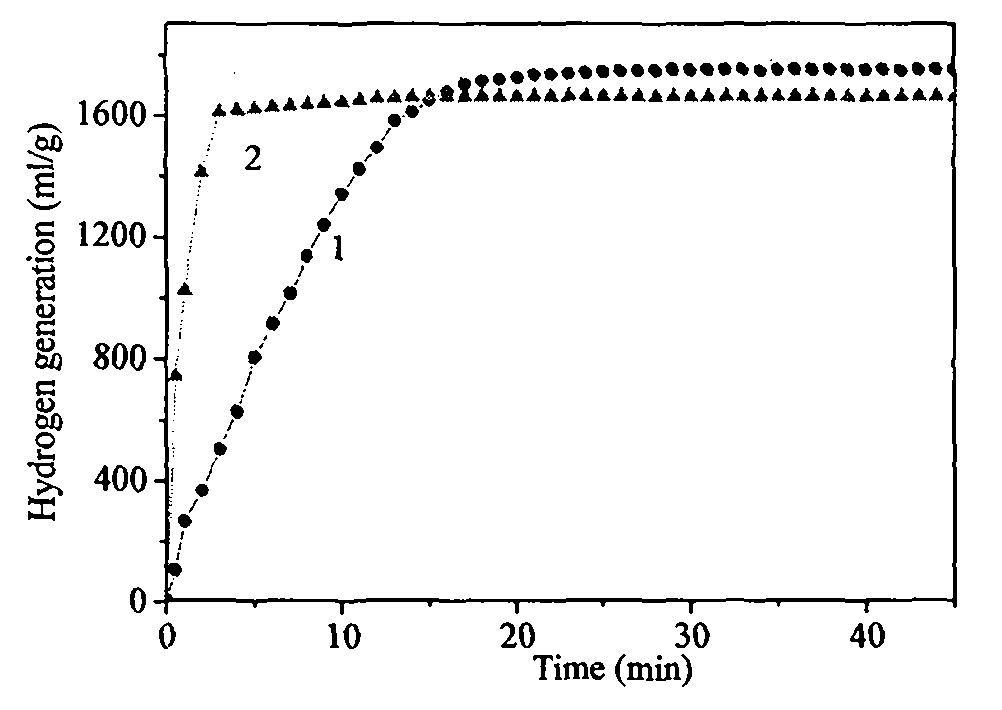

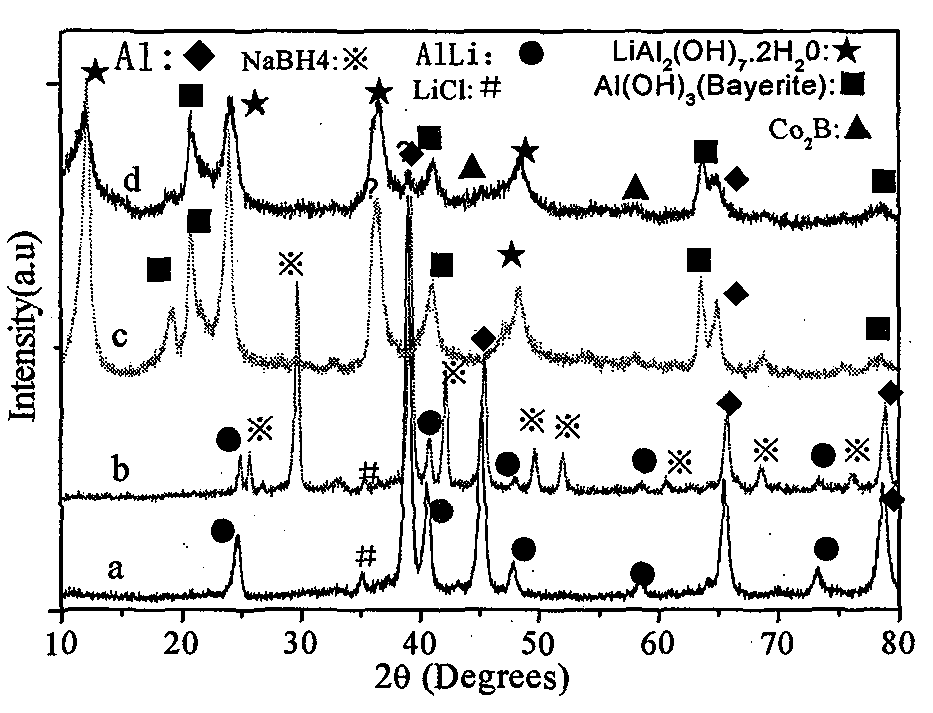

[0033] The system has very good hydrolysis properties in hot water, see figure 1 , the XRD results before and after hydrolysis of the system are shown in figure 2 .

Embodiment 2

[0035] An aluminum alloy / borohydride system for hydrogen production prepared by a combination of ball milling and tableting. Under the protection of argon, the system components were weighed, and the aluminum alloy / borohydride system was prepared by using method 1 in Example 1.

[0036] System composition 2: Al, 20wt%; NaBH 4 , 60wt%; Li, 5wt%; CoCl 2 , 15wt%;

[0037] System composition 3: Al, 60wt%; NaBH 4 , 20wt%; La, 15wt%; Ni, 5wt%;

[0038] System composition 4: Al, 40wt%; NaBH 4 , 40wt%; Li, 10wt%; Ni, 10wt%;

[0039] System composition 5: Al, 50wt%; NaBH 4 , 30wt%; Ca, 15wt%; Co, 5wt%;

[0040]System composition 6: Al, 35wt%; NaBH 4 , 45wt%; Sr, 10wt%; NiCl 2 , 10wt%;

[0041] System component 7: Al, 25wt%; NaBH 4 , 55wt%; Li, 15wt%; Co(NO 3 ) 2 , 5wt%;

[0042] System composition 8: Al, 40wt%; NaBH 4 , 40wt%; Li, 10wt%; CoCl 2 , 10wt%;

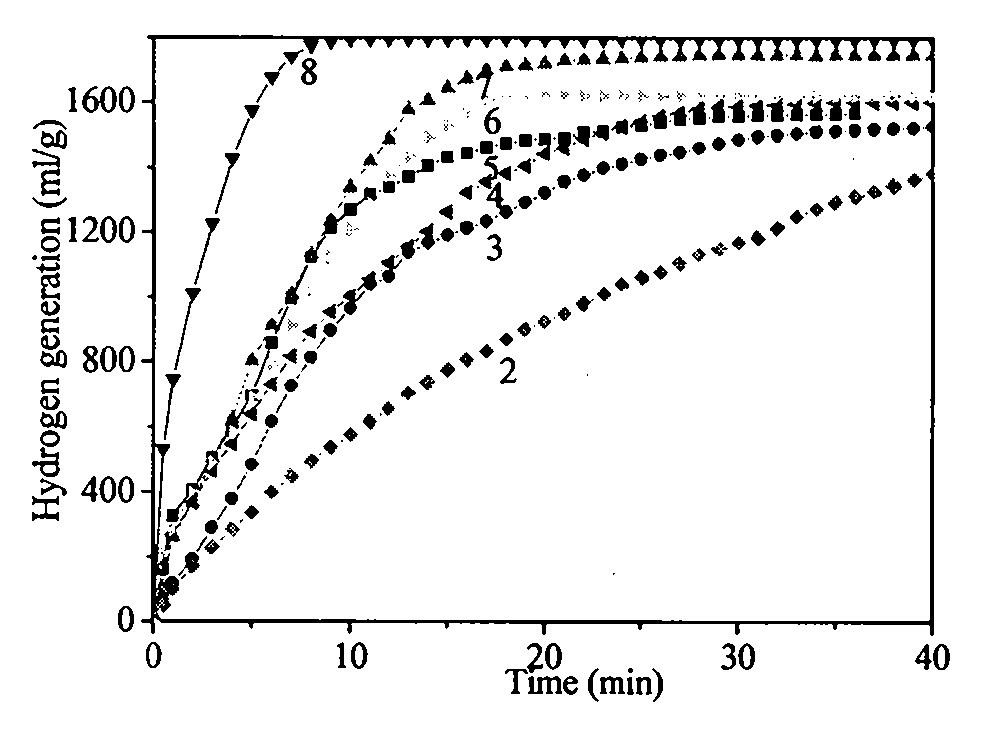

[0043] The aluminum alloy is prepared by mechanical ball milling method. Firstly, the components are weighed, and t...

Embodiment 3

[0045] An aluminum alloy / borohydride system for hydrogen production by hydrolysis, prepared by combining ball milling and tableting. Under the protection of argon, the system components were weighed, and the aluminum alloy / borohydride system was prepared by using method 1 in Example 1.

[0046] System composition 9: Al, 30wt%; BH 3 NH 3 , 40wt%; Li, 15wt%; CoCl 2 , 15wt%;

[0047] System composition 10: Al, 60wt%; KBH 4 , 20wt%; Ca, 10wt%; Ni(NO 3 ) 2 , 10wt%;

[0048] System composition 11: Al, 40wt%; LiBH 4 , 30wt%; La, 20wt%; Ni, 10wt%;

[0049] The aluminum alloy is prepared by mechanical ball milling method. Firstly, the components are weighed, and then mechanically ball milled under the protection of argon. The ball milling time is 400min, the speed is 350r / min, and the ball-to-material ratio is 30:1; then the aluminum alloy and borohydride are mixed and pressed into tablets. Aluminum alloy / borohydride system. The system has very good hydrolysis performance in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com