One-dimensional nanometer photocatalyst as well as preparation method and application thereof

A nano-photocatalyst and catalyst technology, which is applied in the field of photocatalytic materials, can solve the problems of in-depth research on unfavorable catalyst structure regulation of structural relations and high temperature, and achieve high-efficiency photo-splitting water hydrogen production performance, simple preparation method, and high stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

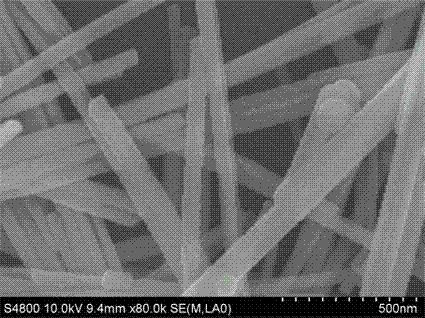

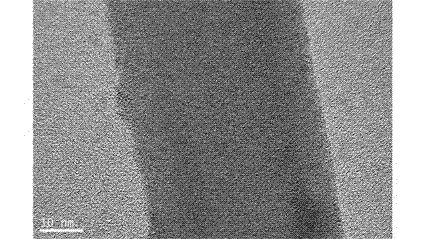

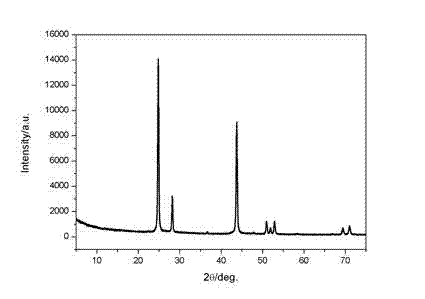

[0040] CdS:MoS 2 Preparation of Composite Nanophotocatalyst

[0041] (1) MoS 2 Preparation of the precursor ammonium tetrathiomolybdate (ATTM): Dissolve 0.05 mol of ammonium molybdate in 300 mL of concentrated ammonia water to prepare a saturated solution; take 21.0 mL of the saturated solution into a three-necked flask, and add 70.0 mL of ammonium sulfide solution. The reaction was carried out at 80 °C for 1 h under magnetic stirring. Cool naturally to room temperature, add ethanol to crystallize for 3 h to obtain MoS 2 Precursor ATTM.

[0042] (2) CdS precursor Cd(S 2 CNEt 2 ) 2 Preparation: 3.0805 g cadmium nitrate (Cd(NO 3 ) 2 ?4H 2 O) and 4.8094 g copper reagent (C 5 h 10 NS 2 Na?3H 2 O) Dissolve in 40 mL and 30 mL of water, then slowly add the copper reagent aqueous solution to the Cd(NO 3 ) 2 In aqueous solution, the CdS precursor Cd(S 2 CNEt 2 ) 2 .

[0043] (3) Preparation of CdS nanorods: 35 mL of ethylenediamine was added to a 50 mL autoclave, and ...

Embodiment 2

[0052] (1) MoS 2 Preparation of the precursor ammonium tetrathiomolybdate (ATTM): Dissolve 0.05 mol of ammonium molybdate in 300 mL of concentrated ammonia water to prepare a saturated solution; take 21.0 mL of the saturated solution into a three-necked flask, and add 70.0 mL of ammonium sulfide solution. The reaction was carried out at 80 °C for 1 h under magnetic stirring. Cool naturally to room temperature, add ethanol to crystallize for 3 h to obtain MoS 2 Precursor ATTM.

[0053] (2) CdS precursor Cd(S 2 CNEt 2 ) 2 Preparation: 3.0805 g cadmium nitrate (Cd(NO 3 ) 2 ?4H 2 O) and 4.8094 g copper reagent (C 5 h 10 NS 2 Na?3H 2 O) Dissolve in 40 mL and 30 mL of water, then slowly add the copper reagent aqueous solution to the Cd(NO 3 ) 2 In aqueous solution, the CdS precursor Cd(S 2 CNEt 2 ) 2 .

[0054] (3) Preparation of CdS nanorods: 35 mL of ethylenediamine was added to a 50 mL autoclave, and then 0.9872 g of Cd(S 2 CNEt 2 ) 2 , and reacted at 180 °C ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com